Method for improving weather resistance of color layer on surface of photovoltaic module

A photovoltaic module and color layer technology, applied in photovoltaic power generation, duplication/marking methods, electrical components, etc., can solve the problems of wasting resource costs, wasting time costs, etc., and achieve the effects of improving weather resistance, reducing costs, and reducing operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

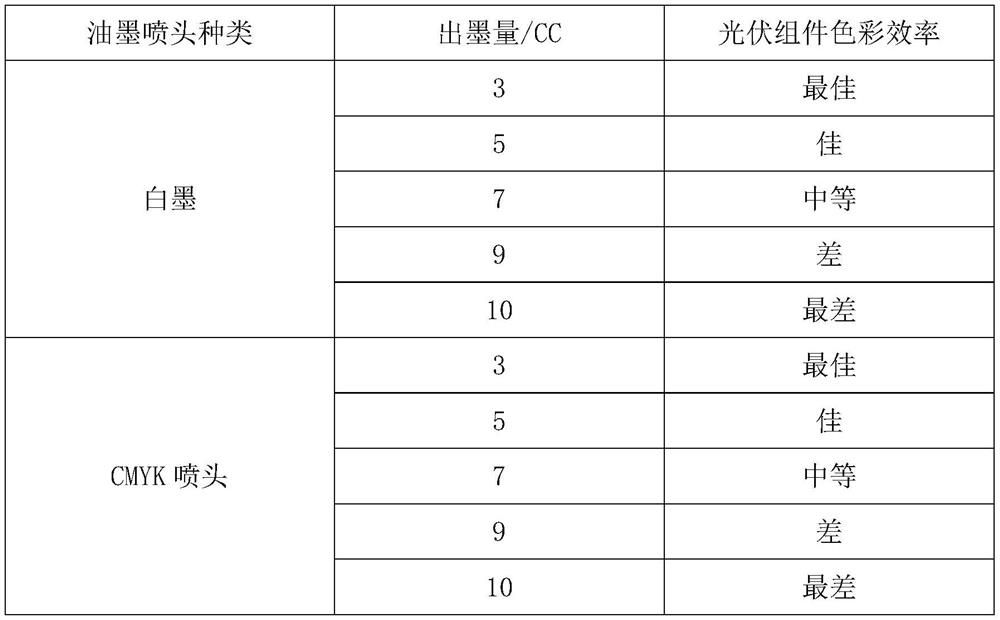

[0041] A method for improving the weather resistance of a color layer on the surface of a photovoltaic module, comprising the following steps:

[0042] S1: Use the ink nozzle and the transparent varnish nozzle to spray the photovoltaic modules at the same time;

[0043] S2: After the color and varnish are simultaneously discharged on the surface of the photovoltaic module, UV curing is performed on the surface of the photovoltaic module.

[0044] The ink nozzle described in step 1 is a magenta nozzle;

[0045] In step 1, the ink output of the magenta nozzle is 3CC per square meter of photovoltaic modules, and the ink output of the transparent varnish nozzle is 3CC per square meter of photovoltaic modules;

[0046] In step 2, ultraviolet curing is to use an ultraviolet lamp with a wavelength of 415 nanometers to irradiate the surface of the photovoltaic module.

[0047] The irradiation time of UV curing in step 2 is 1 second.

Embodiment 2

[0049] A method for improving the weather resistance of a color layer on the surface of a photovoltaic module, comprising the following steps:

[0050] S1: Use the ink nozzle and the transparent varnish nozzle to spray the photovoltaic modules at the same time;

[0051] S2: After the color and varnish are simultaneously discharged on the surface of the photovoltaic module, UV curing is performed on the surface of the photovoltaic module.

[0052] The ink nozzle described in step 1 is a cyan nozzle;

[0053] In step 1, the ink output of the cyan nozzle is 5CC per square meter of photovoltaic modules, and the ink output of the transparent varnish nozzle is 5CC per square meter of photovoltaic modules;

[0054] In step 2, ultraviolet curing is to use an ultraviolet lamp with a wavelength of 420 nanometers to irradiate the surface of the photovoltaic module.

[0055] The irradiation time for UV curing in step 2 was 0.5 seconds.

Embodiment 3

[0057] A method for improving the weather resistance of a color layer on the surface of a photovoltaic module, comprising the following steps:

[0058] S1: Use the ink nozzle and the transparent varnish nozzle to spray the photovoltaic modules at the same time;

[0059]S2: After the color and varnish are simultaneously discharged on the surface of the photovoltaic module, UV curing is performed on the surface of the photovoltaic module.

[0060] The ink nozzle described in step 1 is a black nozzle;

[0061] In step 1, the ink output of the yellow nozzle is 7CC per square meter of photovoltaic modules, and the ink output of the transparent varnish nozzle is 7CC per square meter of photovoltaic modules;

[0062] In step 2, ultraviolet curing is to irradiate the surface of the photovoltaic module with an ultraviolet lamp with a wavelength of 365 nanometers.

[0063] The irradiation time of UV curing in step 2 was 3 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com