Low-cost high-strength full-biodegradable agricultural mulching film and in-situ reaction extrusion plasticizing compatibilization preparation process thereof

A kind of agricultural mulching film, in situ reaction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A low-cost and high-strength fully biodegradable agricultural mulching film in-situ reaction extrusion plasticization and compatibilization preparation process, comprising the following steps:

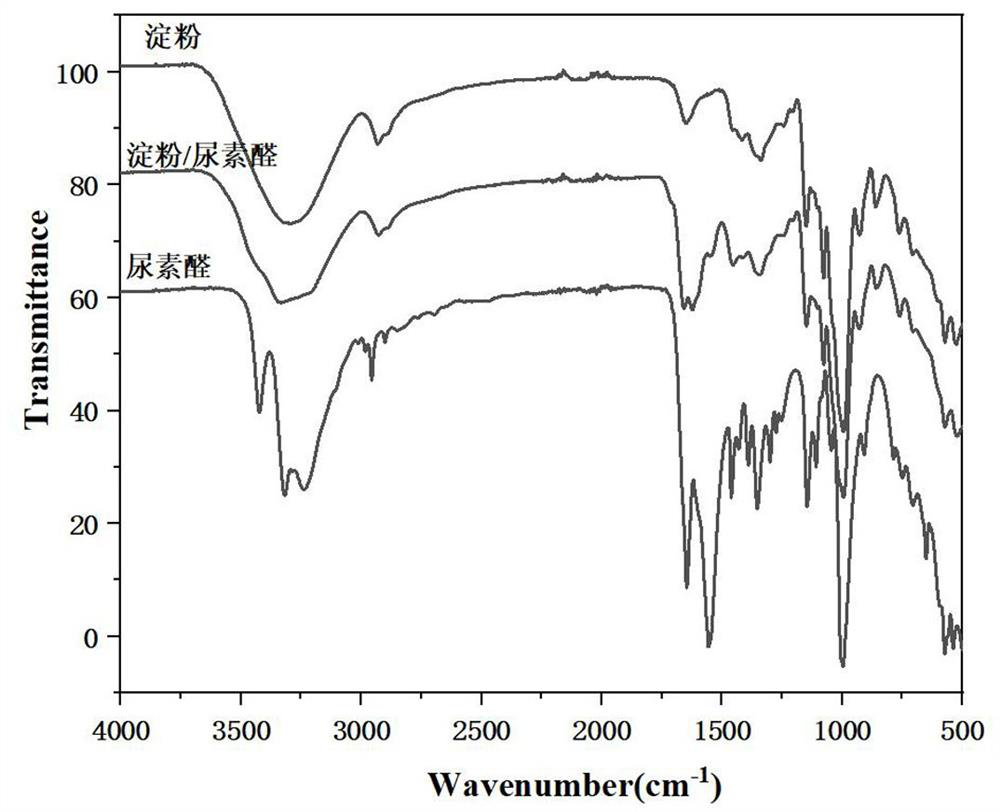

[0071] (1) add 20g formaldehyde and 24g urea respectively, adjust the pH of the system=9, and react at 50°C for 2h to obtain a methylol urea solution;

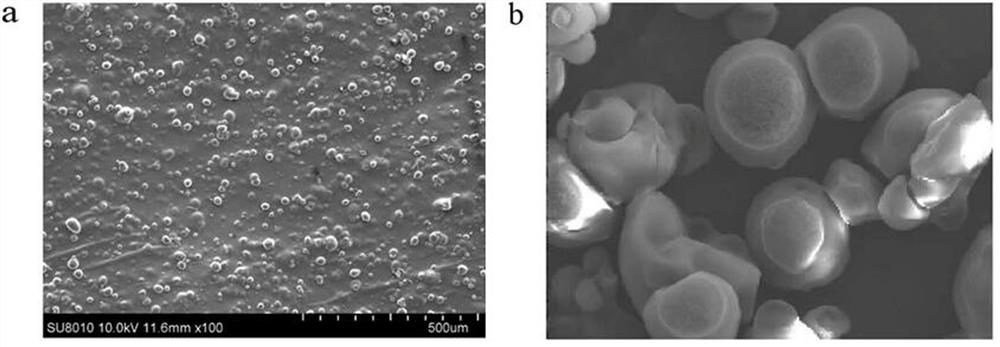

[0072] (2) 10 parts of methylol urea solutions obtained in step (1) are mixed with 10 parts of tapioca starch powder to obtain 20 parts of methylol urea plasticized tapioca starch;

[0073] (3) 20 parts of methylol urea plasticized tapioca starch obtained in step (2), 65 parts of PBAT, 1 part of chain extender X-U993, 4 parts of compatibilizer maleic anhydride, 10 parts of talcum powder were mixed until uniform ;

[0074] (4) adding the homogeneously mixed raw material obtained in step (3) into a twin-screw extruder for extrusion, the temperature of each zone of the twin-screw extruder is set at 130° C., and the extrudate is co...

Embodiment 2

[0077] A low-cost and high-strength fully biodegradable agricultural mulching film in-situ reaction extrusion plasticization and compatibilization preparation process, comprising the following steps:

[0078] (1) add 20g formaldehyde and 24g urea respectively, adjust the pH of the system=9, and react at 50°C for 2h to obtain a methylol urea solution;

[0079] (2) 8 parts of methylol urea solutions obtained in step (1) are mixed with 12 parts of tapioca starch powder to obtain 20 parts of methylol urea plasticized tapioca starch;

[0080] (3) 20 parts of methylol urea plasticized tapioca starch obtained in step (2), 65 parts of PBAT, 1 part of chain extender X-U993, 4 parts of compatibilizer maleic anhydride, 10 parts of talcum powder were mixed until uniform ;

[0081] (4) adding the homogeneously mixed raw material obtained in step (3) into a twin-screw extruder for extrusion, the temperature of each zone of the twin-screw extruder is set at 130° C., and the extrudate is col...

Embodiment 3

[0084] A low-cost and high-strength fully biodegradable agricultural mulch film and its in-situ reaction extrusion, plasticization and compatibilization preparation process, comprising the following steps:

[0085] (1) add 20g formaldehyde and 24g urea respectively, adjust the pH of the system=9, and react at 50°C for 2h to obtain a methylol urea solution;

[0086] (2) 6 parts of methylol urea solutions obtained in step (1) are mixed with 14 parts of starch powders to obtain 20 parts of methylol urea plasticized tapioca starch;

[0087] (3) 20 parts of methylol urea plasticized tapioca starch obtained in step (2), 65 parts of PBAT, 1 part of chain extender X-U993, 4 parts of compatibilizer maleic anhydride, 10 parts of talcum powder were mixed until uniform ;

[0088] (4) adding the homogeneously mixed raw material obtained in step (3) into a twin-screw extruder for extrusion, the temperature of each zone of the twin-screw extruder is set at 130° C., and the extrudate is cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com