Polyvinyl butyral blending enhanced polyvinylidene chloride membrane and preparation method thereof

A technology of polyvinyl butyral and polyvinylidene chloride, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problem that polyvinylidene chloride membranes have poor mechanical properties and cannot be used as micro-ultrafiltration membranes Material and other issues, to achieve the effect of controllable pore size, low cost, and enhanced tensile elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

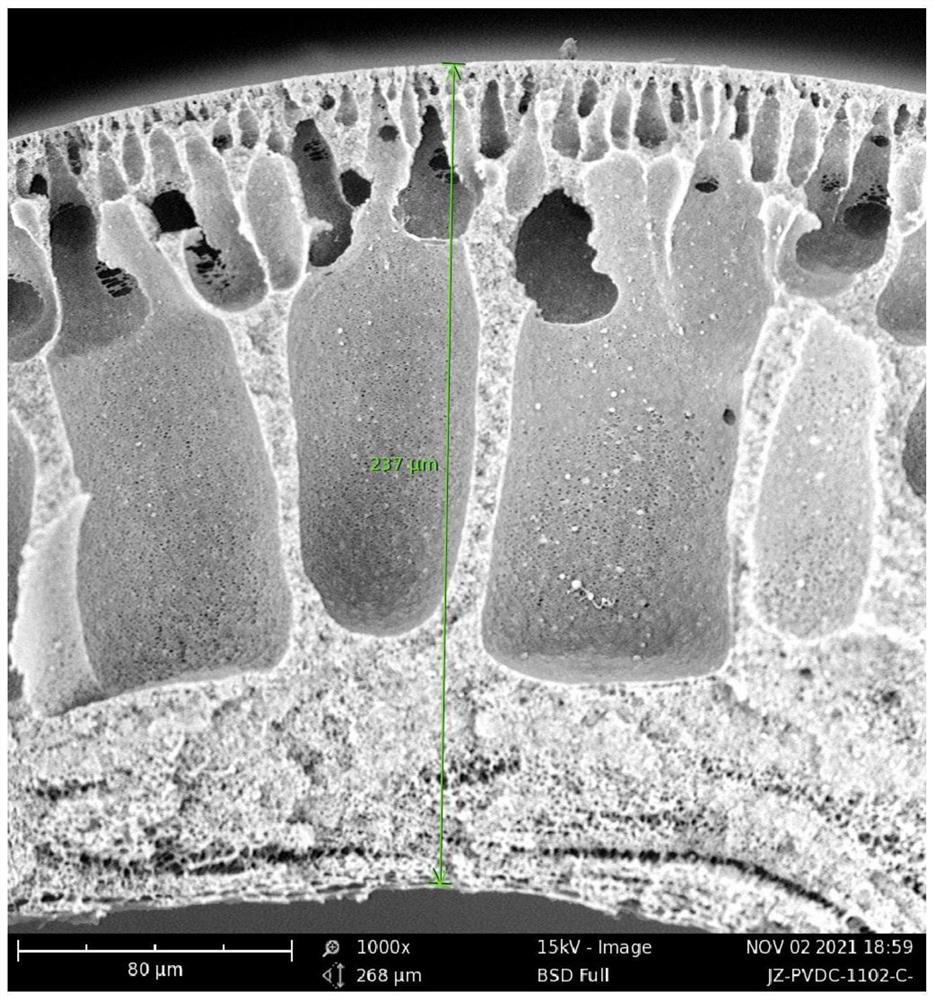

[0035] Mix 360g of PVDC with a degree of polymerization of 1900, 40g of PVB with a viscosity of 400mPa.s, 200g of polyvinylpyrrolidone with a molecular weight of 10000, 100g of ethylene glycol, and 1300g of dimethylacetamide at 50°C, stir and dissolve for 24 hours, and remove Soak to obtain the casting solution, apply the casting solution on a clean glass plate with a 100 μm thick spatula at 40°C, and after standing for 10 seconds, completely immerse the film in a mixed solution of ethylene glycol and dimethylacetamide at 40°C The medium gel is solidified and shaped for 60s, then taken out and placed in pure water, soaked at room temperature for 12 hours, then transferred to an oven for 12 hours at 40°C;

[0036] Using a scanning electron microscope to observe the cross-section of the filter membrane, the photo is as follows figure 1 shown.

Embodiment 2

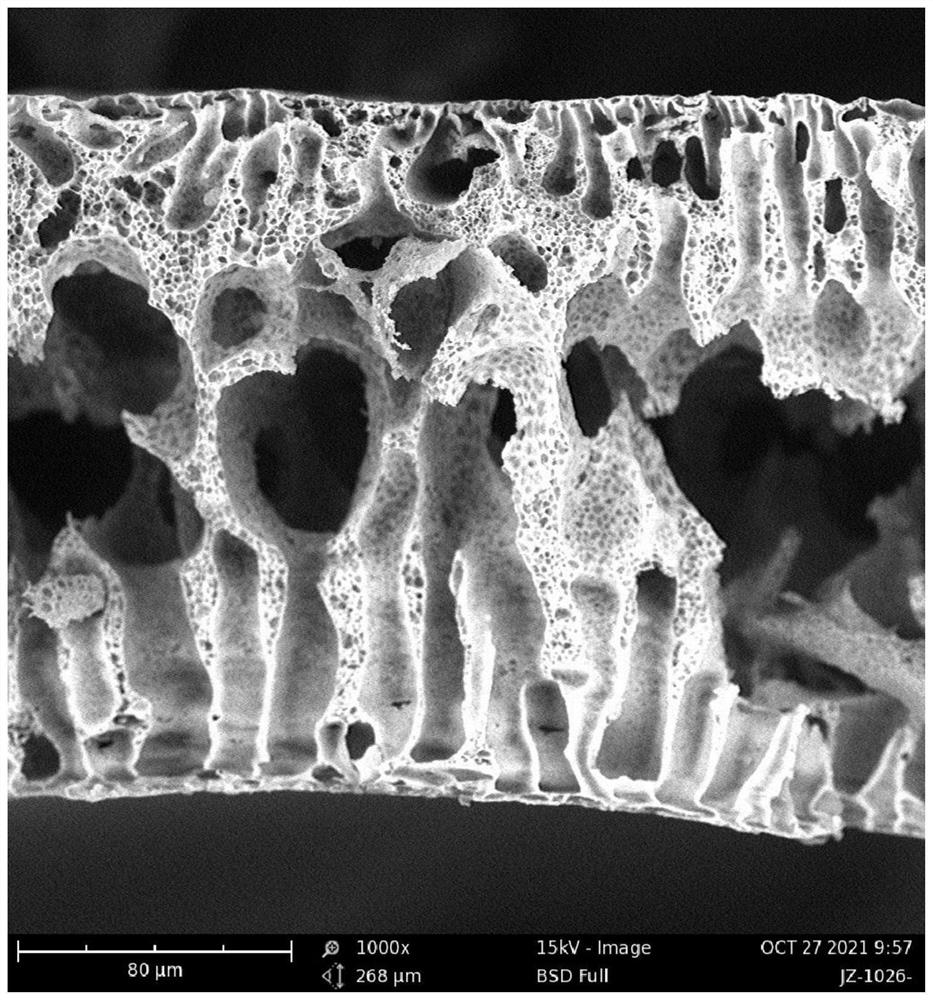

[0038] Mix 360g of PVDC with a polymerization degree of 1900, 40g of PVB with a viscosity of 3000mPa.s, 200g of polyvinylpyrrolidone with a molecular weight of 10000, 100g of ethylene glycol, and 1300g of dimethylacetamide at 50°C, stir and dissolve for 24 hours, and defoam To obtain the casting solution, apply the casting solution on a clean glass plate with a 100 μm thick spatula at 40°C, and after standing for 10 seconds, completely immerse the film in a mixed solution of ethylene glycol and dimethylacetamide at 40°C The gel was solidified and shaped for 60 seconds, then taken out and soaked in pure water at room temperature for 12 hours, then transferred to an oven for 12 hours at 40°C.

Embodiment 3

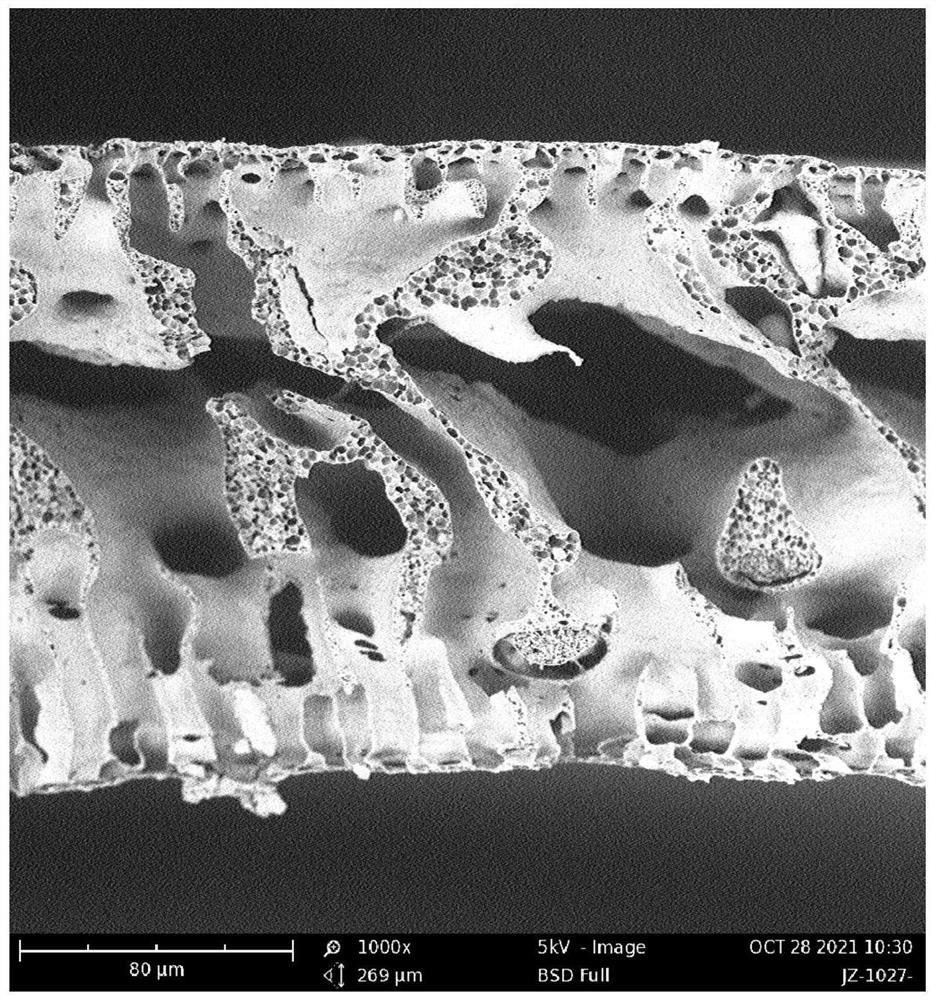

[0040]Mix 360g of PVDC with a degree of polymerization of 1900, 100g of PVB with a viscosity of 400mPa.s, 180g of polyvinylpyrrolidone with a molecular weight of 10,000, 100g of ethylene glycol, and 1260g of dimethylacetamide at 50°C, stir and dissolve for 24 hours, and defoam to obtain a casting Film solution, at 40°C, apply the film casting solution on a clean glass plate with a 100 μm thick spatula, and then completely immerse the film in a mixed solution of ethylene glycol and dimethylacetamide at 40°C for gel curing and forming for 60s , then taken out and soaked in pure water at room temperature for 12 hours, then transferred to an oven for drying at 40°C for 12 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com