Sonar control circuit

A control circuit and sonar technology, applied in the direction of comprehensive factory control, sound wave re-radiation, electrical digital data processing, etc., can solve the problem of sound wave sample point calculation without complex signal processing, low processing performance, less data acquisition and monitoring channels, etc. problems, to achieve the effect of rich communication interfaces, strong processing performance, and fast real-time response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

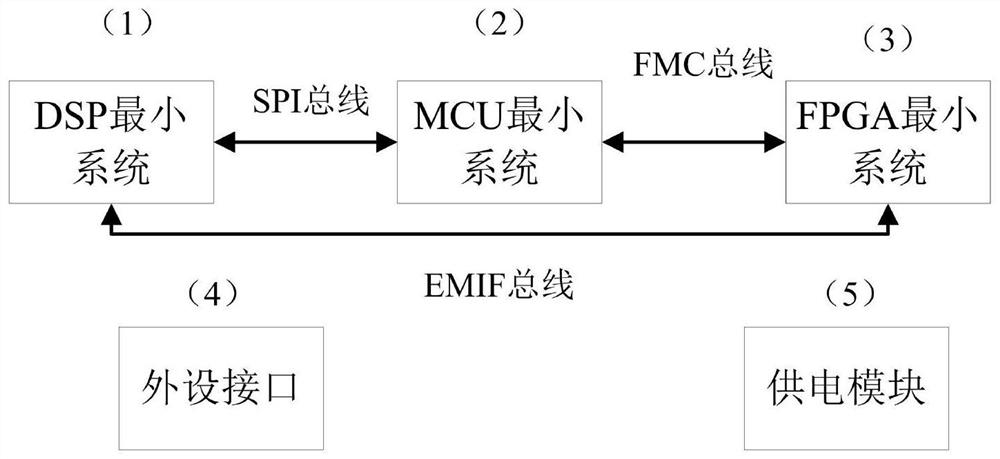

see Figures 1~10 As shown, this embodiment specifically discloses and provides a technical solution for a sonar control circuit, including:

DSP minimum system 1: The main function is to realize complex sample emission signal generation, PWM generation, and complex signal processing;

MCU minimum system 2: The main function is to realize data communication, acquisition and recording;

FPGA minimum system 3: The main function realizes multi-channel data acquisition and control;

Peripheral interface 4: Provide all data collection, transmission and recording;

Power supply module 5: Provide stable and reliable power supply for the entire sonar control circuit.

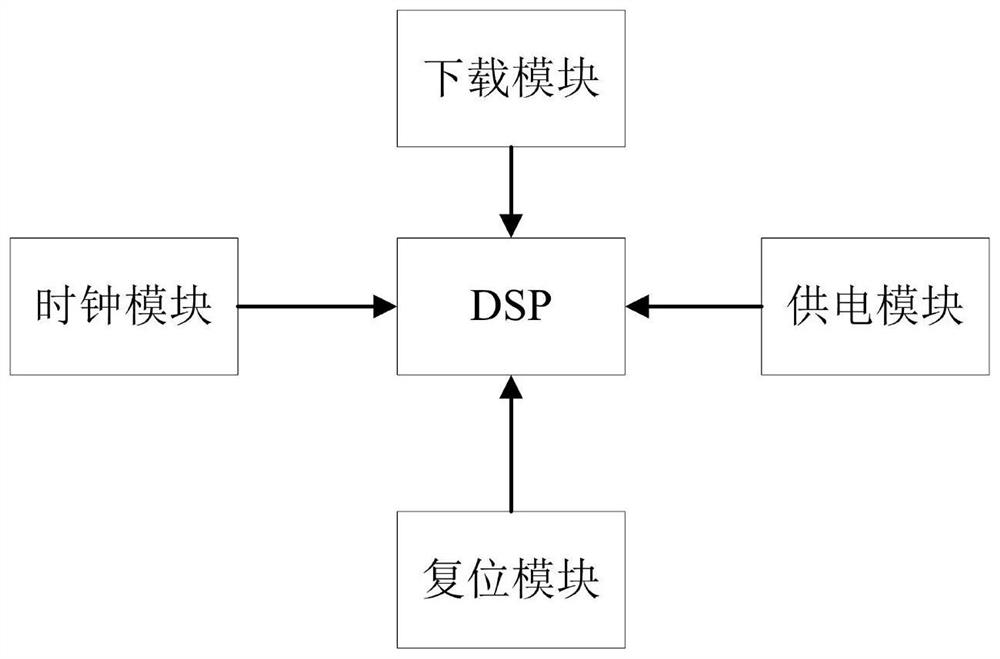

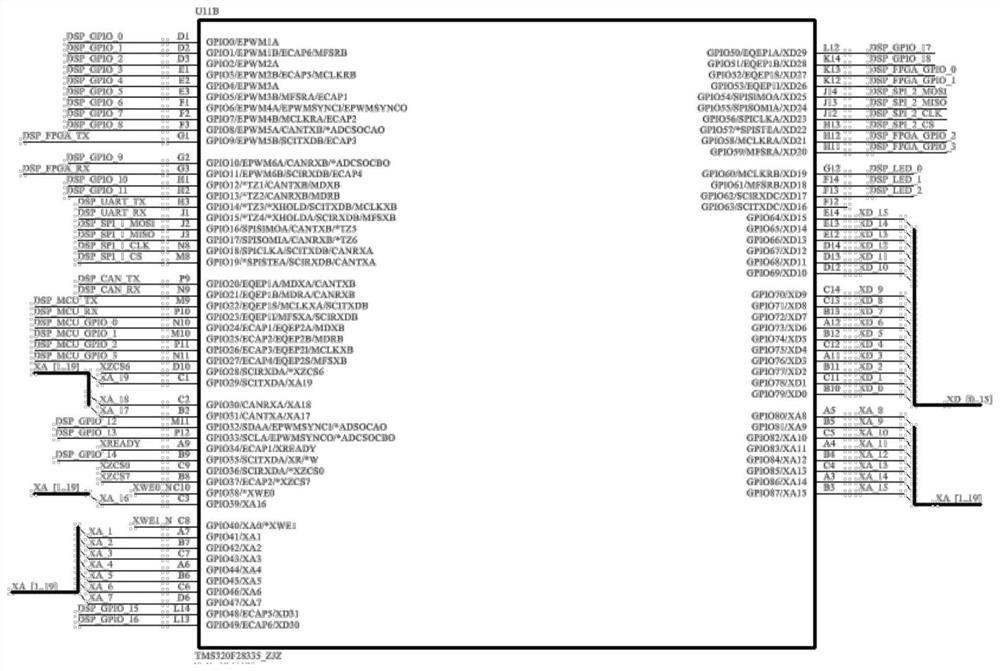

[0031] DSP minimum system 1 such as figure 2 As shown: the DSP minimum system 1 and the MCU minimum system 2 communicate through the SPI bus, and the MCU minimum system 2 and the FPGA minimum system 3 realize data transmission through the FMC parallel bus. Data communication is implemented between the DSP minimum sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com