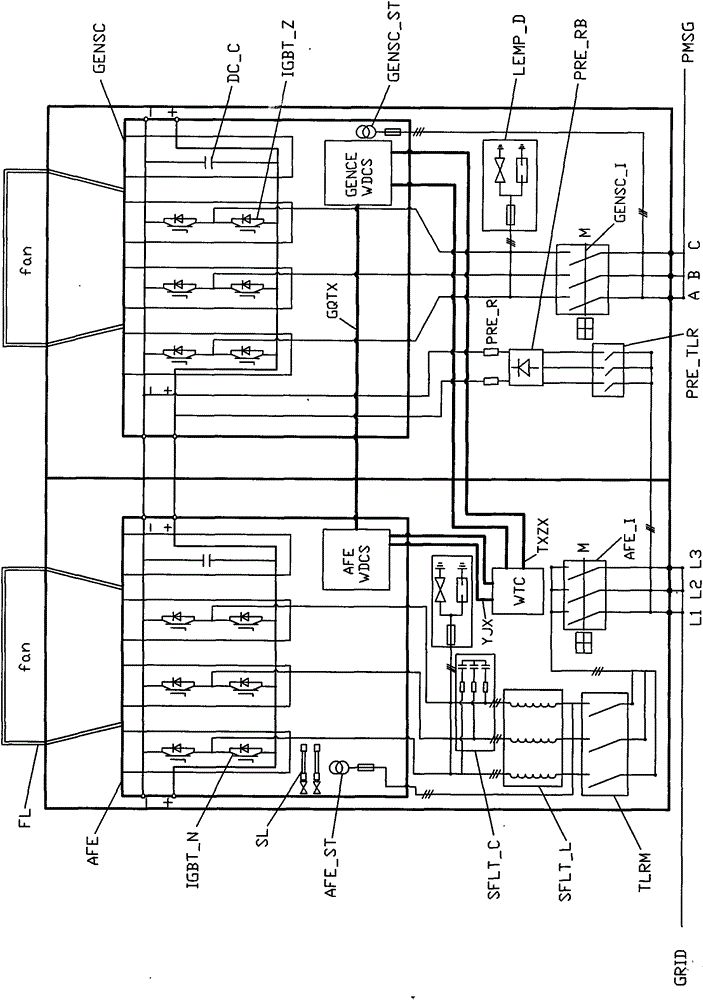

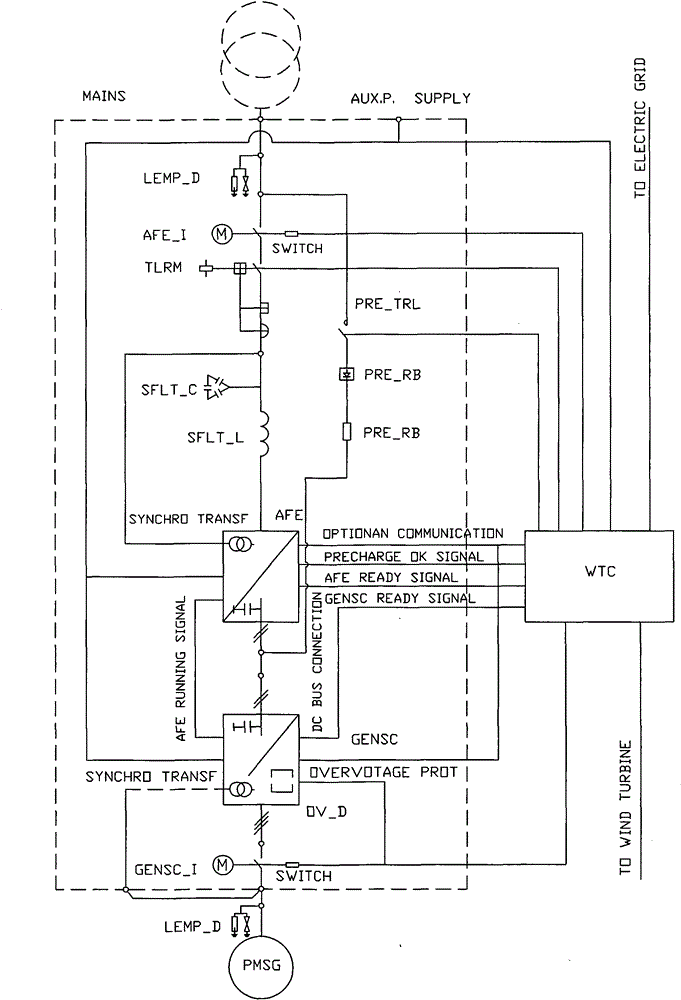

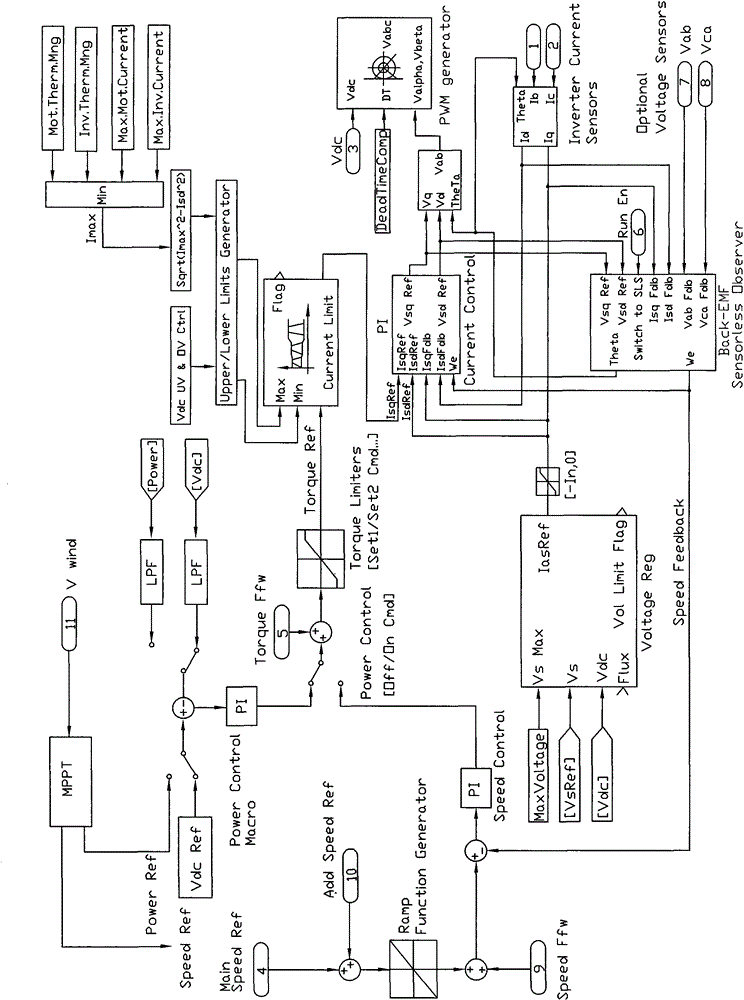

Megawatt-level permanent magnet direct-drive wind-force generating converter and control method

A control method and converter technology, applied in wind power converter equipment and control, megawatt-level permanent magnet direct drive wind power converter and control field, can solve the problem of low safety, limited monitoring facilities, system Poor safety and other issues, to achieve the effect of compact mechanical structure, convenient maintenance and disassembly, and safe and reliable communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Embodiment The megawatt-level permanent magnet direct-drive wind power converter adopts the following risk prevention measures:

[0047] a. The fault operation protection of the converter and the overvoltage protection of DC adopt the hardware and software protection of the converter itself;

[0048] b. The overvoltage and overcurrent protection of the converter is realized by using the hardware setting and software control of the inverter unit AFE and the rectifier unit GENSC, combined with the rectifier unit side break protection GENSC_I and the inverter unit side break protector AFE_I;

[0049] c. For the overcurrent protection of the generator PMSG, the maximum current control is realized by starting the torque-controlled current limiter of the rectifier unit GENSC, and at the same time superimposed protection is realized by the overcurrent protection accessory of the rectifier unit side breaker GENSC_I;

[0050] d. The overvoltage protection of the generator PMSG i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com