High-entropy alloy coating material with high wear resistance

A high-entropy alloy and coating material technology, which is applied in the direction of metal material coating technology, coating, and energy efficiency improvement, can solve the problems of inability to apply, prepare high-entropy alloy coatings, and inability to carry out large-scale production, and achieve Meet performance requirements, reduce production costs, improve hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

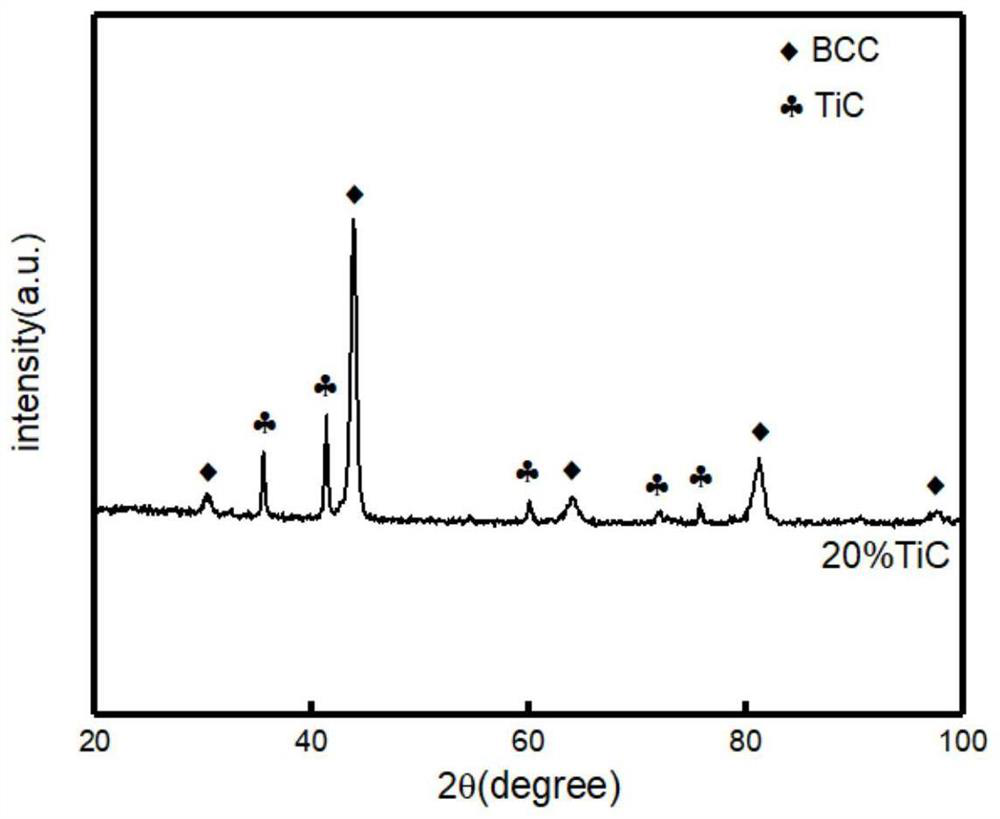

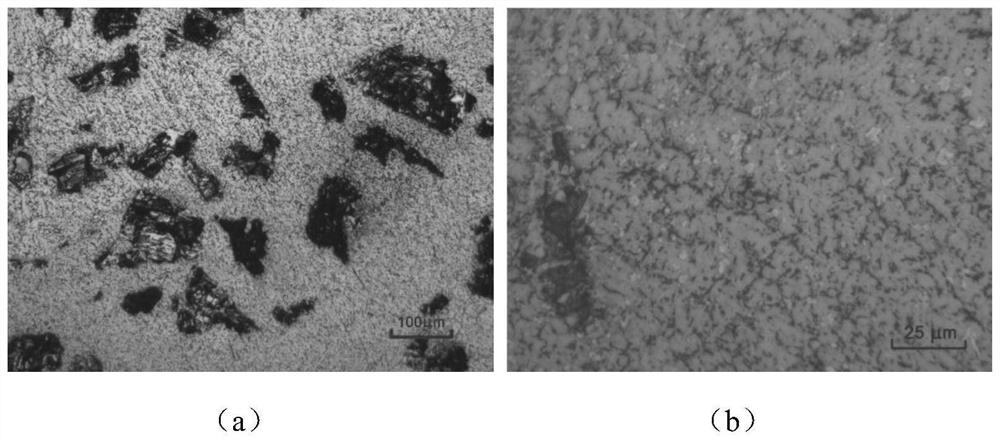

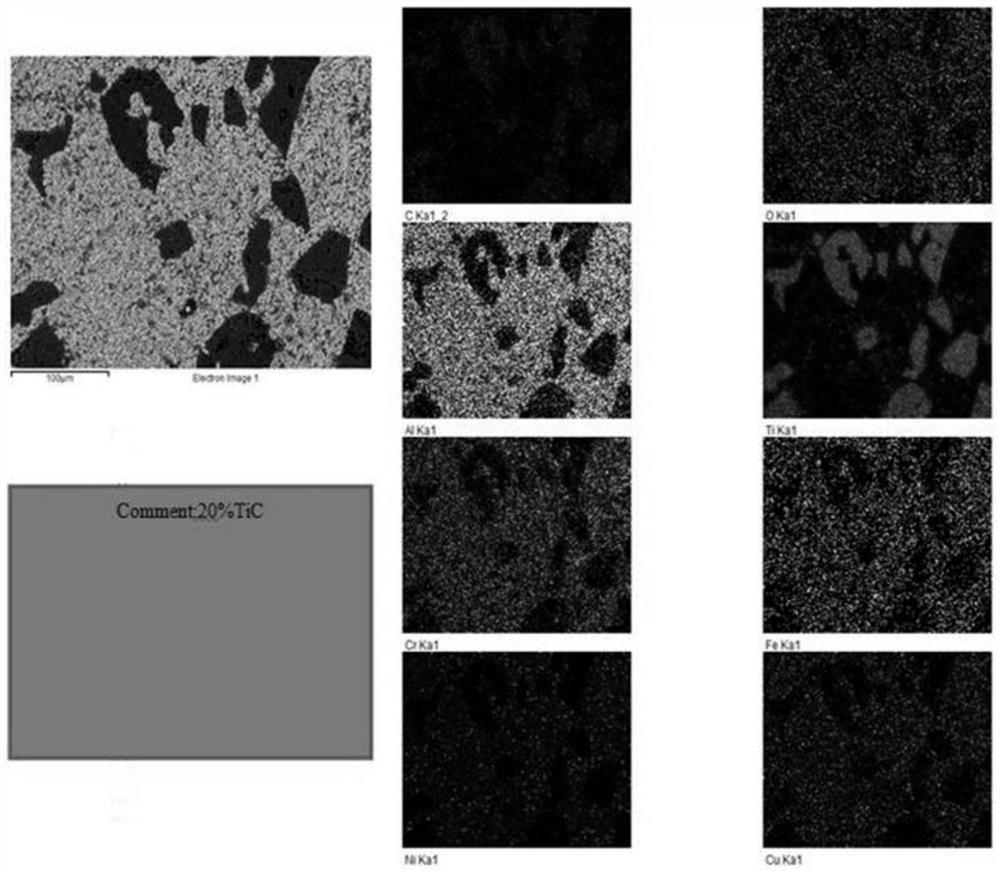

[0050] Example: Preparation of high wear-resistant high-entropy alloy coating

[0051] 1) According to the content of Al, Cr, Cu, Fe and Ni in the coating composition, according to the mass percentage of Al 14.41%, Cr 15.41%, Cu18.84%, Fe 16.55%, Ni 34.79%, it is prepared and smelted into an alloy melt , Prepare alloy powder by gas atomization method, atomization temperature is about 1500 ℃, atomization pressure is about 4.5MPa, equipment model YC2017-0062# vacuum air atomization equipment. This powder has good fluidity, uniform distribution of elements, and excellent physical properties. Add TiC powder, use YC2019-0061# vacuum ball mill mixer to mix powder under vacuum condition for 36h, the rotation speed is 3000r / min, to form Al with TiC mass fraction of 20% 1.8 CrCuFeNi 2 +TiC powder;

[0052] 2) Put the mixed alloy powder into a dryer for drying, the heating rate is 4°C / min, and dry for 1 hour to obtain dry powder. The purpose of drying is to remove the residual moistu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com