Method for comprehensively recovering lignite rich in rare elements

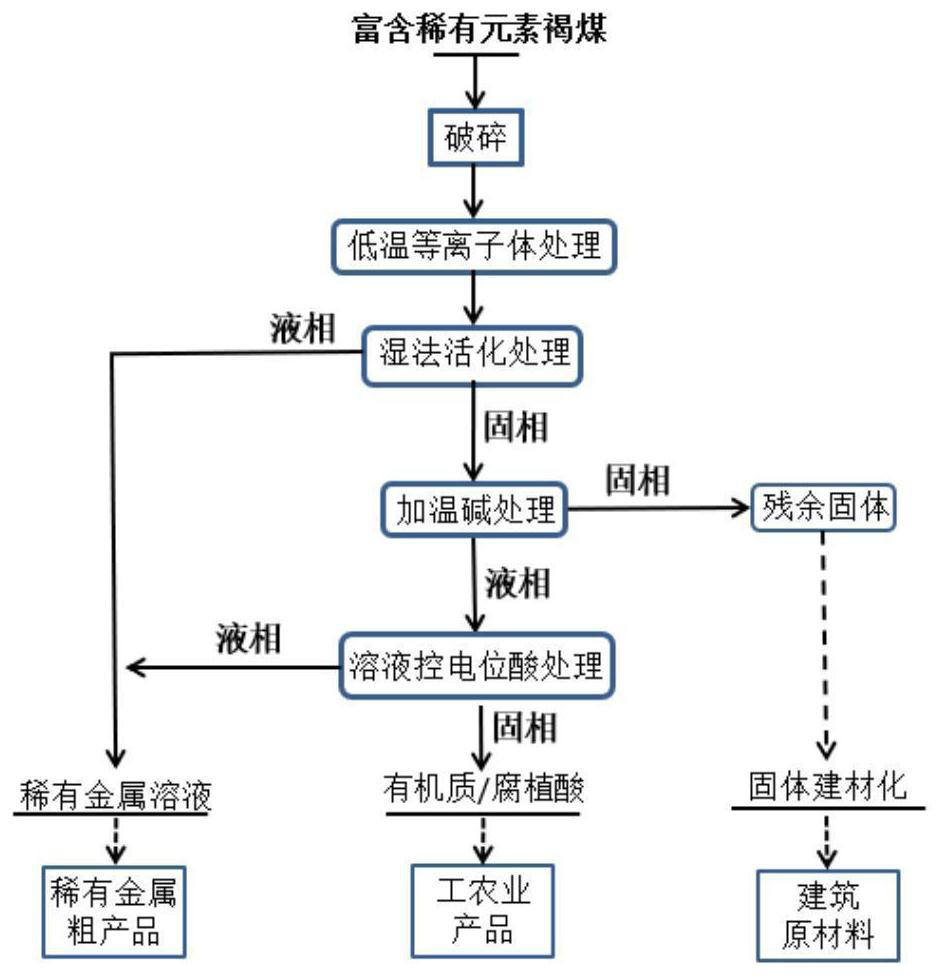

A technology for rare elements and rare earth elements, applied in the field of comprehensive recovery of lignite rich in rare elements, can solve the problems of low lignite ash volatilization rate, difficult to guarantee atmosphere, long volatilization time, etc. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

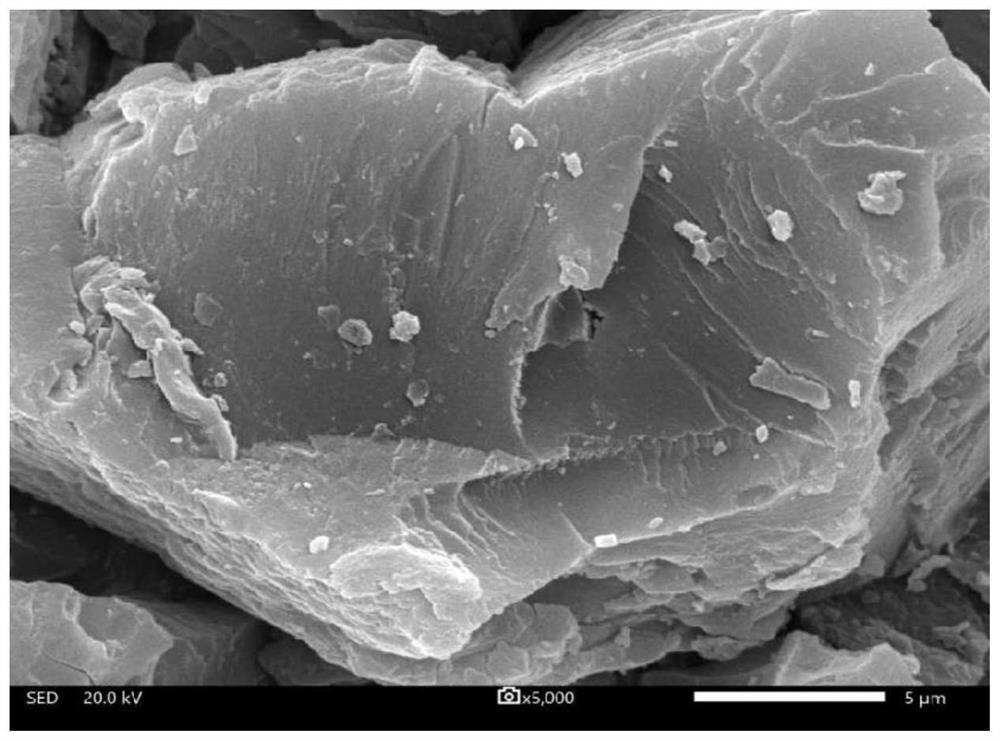

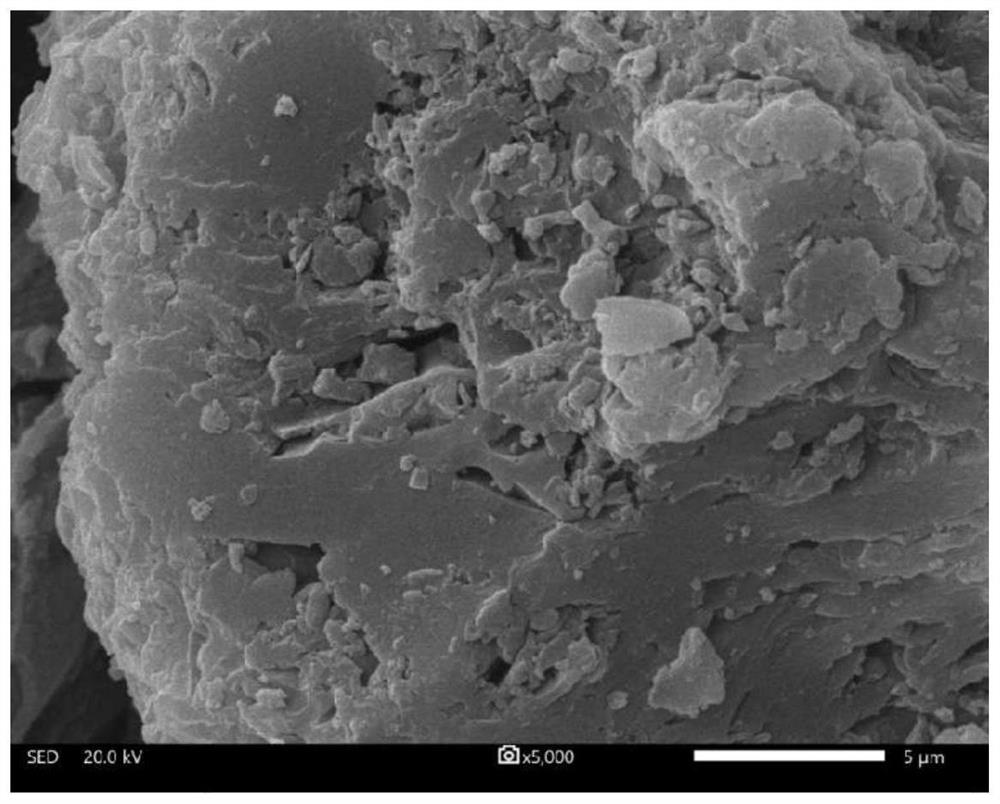

[0046] For a lignite containing germanium 106ppm and rare earth 58ppm in Inner Mongolia (the moisture content is about 20%), the raw coal is first broken into small particles below 80 mesh, and then the coal sample is subjected to low temperature plasma treatment, and the lignite raw material is put into the low temperature plasma In the processing device, pass O 2 , the control discharge power is 200W, the thickness of lignite is 3mm, the speed of the container in the cabin is 20rpm, and it is treated at 100 ℃ for 2h. After the treatment, the treated coal sample is obtained; The activator mixed at 100:1 was slowly added dropwise to the treated coal sample, the solid-liquid ratio was 1:3, the solution temperature was controlled at 25 °C, and the solution was stirred for 10 hours. It is used to continue extracting rare metals; after washing the solid after solid-liquid separation, add 5% sodium hydroxide solution (10% of which is sodium tripolyphosphate), the solid-liquid ratio...

Embodiment 2

[0050] Other conditions are the same as those in Example 1, the difference is: during low-temperature plasma treatment, N 2 , the reaction atmosphere is nitrogen atmosphere; finally, the total dissolution rate of germanium is 93.83%, the total dissolution rate of rare earth is 83.05%, and the yield of organic matter is 41.29%. Through the comparison between Comparative Example 3 and Example 1, it is found that in the low temperature plasma treatment, the effect of using oxygen is better than that of using nitrogen.

Embodiment 3

[0054] The other conditions are the same as those in Example 1, except that the low-temperature plasma treatment time is 6h;

[0055] Finally, the total dissolution rate of germanium was 94.23%, the total dissolution rate of rare earth was 82.94%, and the yield of organic matter was 40.02%. Through Comparative Example 3 and Example 1, it is found that long-term low-temperature plasma treatment will lead to a significant decrease in the yield of organic matter, and the dissolution rate of rare earth has begun to decline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com