Super-amphiphobic self-cleaning brightening composite coating and preparation method thereof

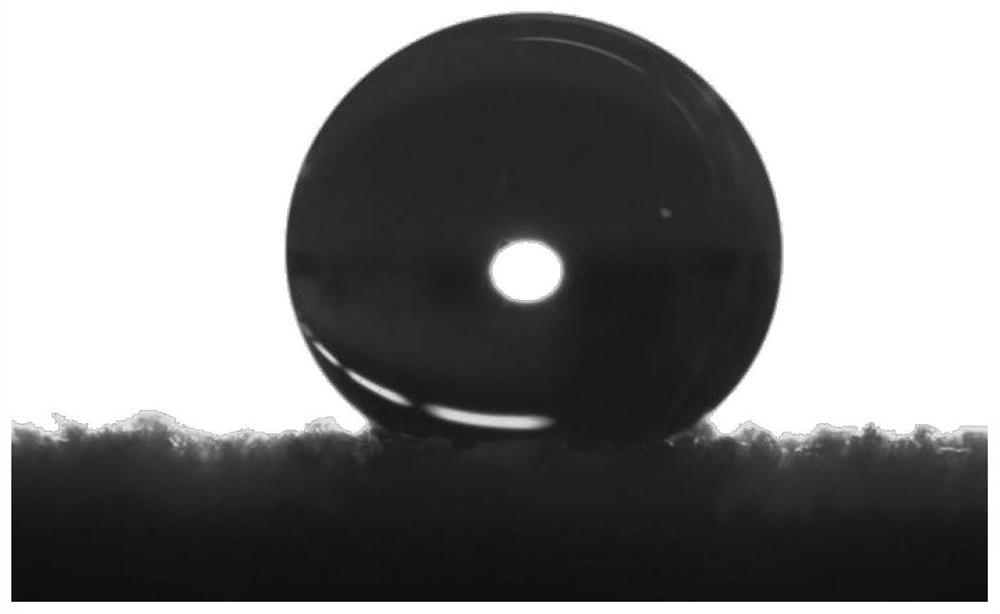

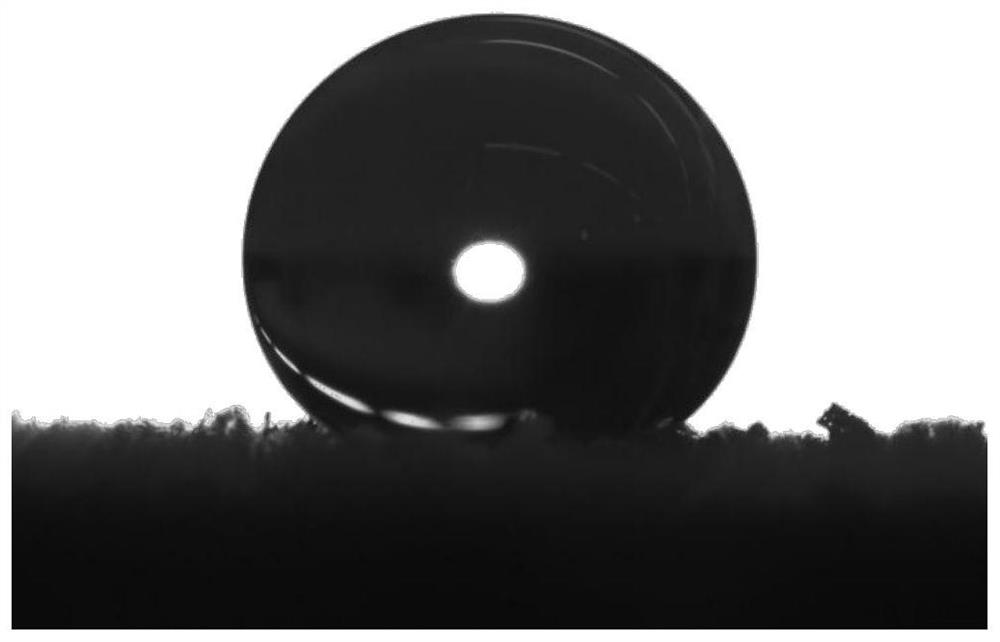

A composite coating and self-cleaning technology, applied in anti-corrosion coatings, epoxy resin coatings, reflection/signal coatings, etc., can solve problems affecting the effect of brightening, surface cracking, insufficient lighting, etc., to increase reflectivity and diffuse reflection , resistance to impact damage, and the effect of increasing roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing a super-amphiphobic self-cleaning and brightening composite coating, comprising the following steps:

[0046] S1: Add resin and additives into 20 parts of organic solvent, and stir at 200rpm;

[0047] S2: adding the reflective material to the stirring vessel in step S1 in three stages, and stirring for 10 minutes after each stage;

[0048] S3: carry out ultrasonic dispersion for 0.5h;

[0049] S4: adding a coupling agent and a fluorosilane agent, and performing ultrasonic dispersion for 1 hour to obtain a component A stock solution;

[0050] S5: The first component stock solution obtained in step S4 is placed in a constant temperature water bath at 50°C and stirred for 2 h to obtain the first component;

[0051] S6: Take the resin curing agent as the B component and stir and mix with the A component to obtain a composite coating.

Embodiment 1

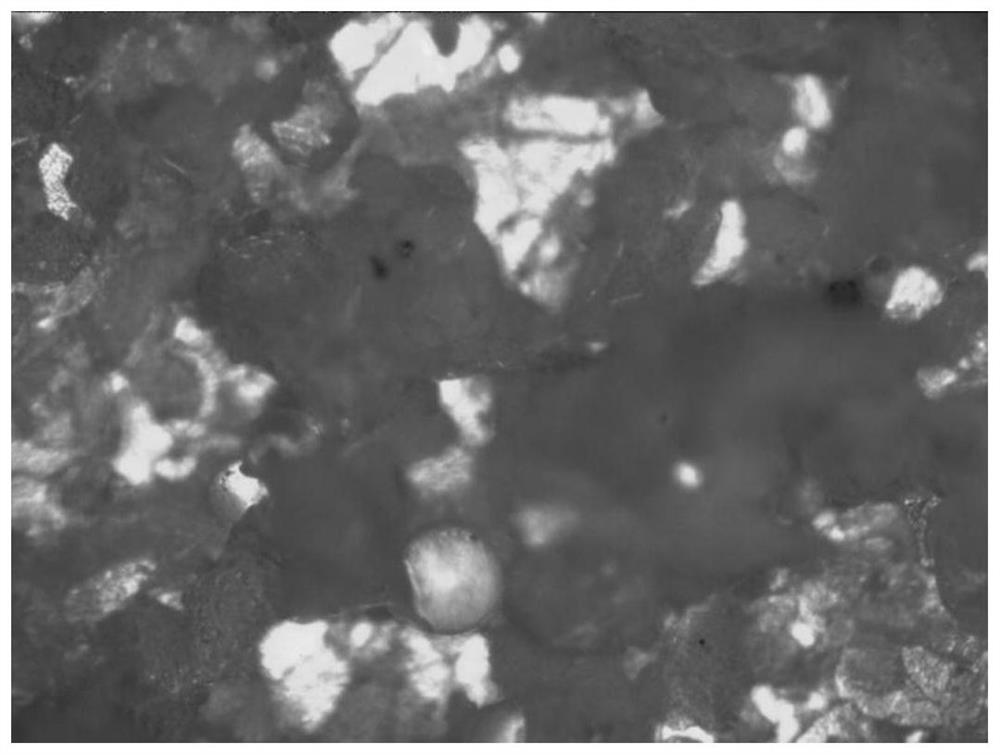

[0053] Component A: Disperse 10 parts of epoxy resin in 20 parts of anhydrous ethanol solution, stir at 200 rpm for 10 minutes at 40 °C, then add 27 parts of glass microbead powder, continue stirring for 10 minutes, and then add 6 parts Pearlescent powder, continue to stir for 10min, add 2 parts of titanium dioxide, stir for 10min, ultrasonically disperse at 50 ° C for 0.5h, after the ultrasonic dispersion is completed, add 2 parts of coupling agent, 5 parts of ammonia water, 5 parts of ethyl orthosilicate, 0.5 Parts of perfluorodecyl triethoxysilane and 5 parts of deionized water were dispersed in ultrasonic waves at 50°C for 1 hour, and then placed in a constant temperature water bath at 50°C and stirred for 2 hours to obtain component A.

[0054] The composition of component B is 10 parts of resin curing agent.

Embodiment 2

[0056] Component A: Disperse 10 parts of epoxy resin in 20 parts of ethyl acetate solution, under the condition of rotating speed of 200rpm, mechanically stir at 20°C for 10min, then add 27 parts of glass microbead powder, continue stirring for 10min and then add 6 parts Pearlescent powder, continue to stir for 10min, add 2 parts of titanium dioxide, after stirring for 10min, ultrasonically disperse at 20°C for 0.5h, add 2 parts of coupling agent, 5 parts of ammonia water, 5 parts of ethyl orthosilicate, 0.5 parts of perfluoro Decyl triethoxysilane, 5 parts of deionized water, ultrasonically dispersed for 1 hour, placed in a constant temperature water bath at 20° C. and stirred for 2 hours to prepare component A.

[0057] The composition of component B is 10 parts of resin curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com