Thermochromic sheet as well as preparation process and application thereof

A thermochromic, sheet technology, applied in the direction of films/sheets without carriers, film/sheet adhesives, synthetic resin layered products, etc. Circuit damage and other problems, to avoid circuit obstacles, good viewing visual effects, and wide discoloration temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

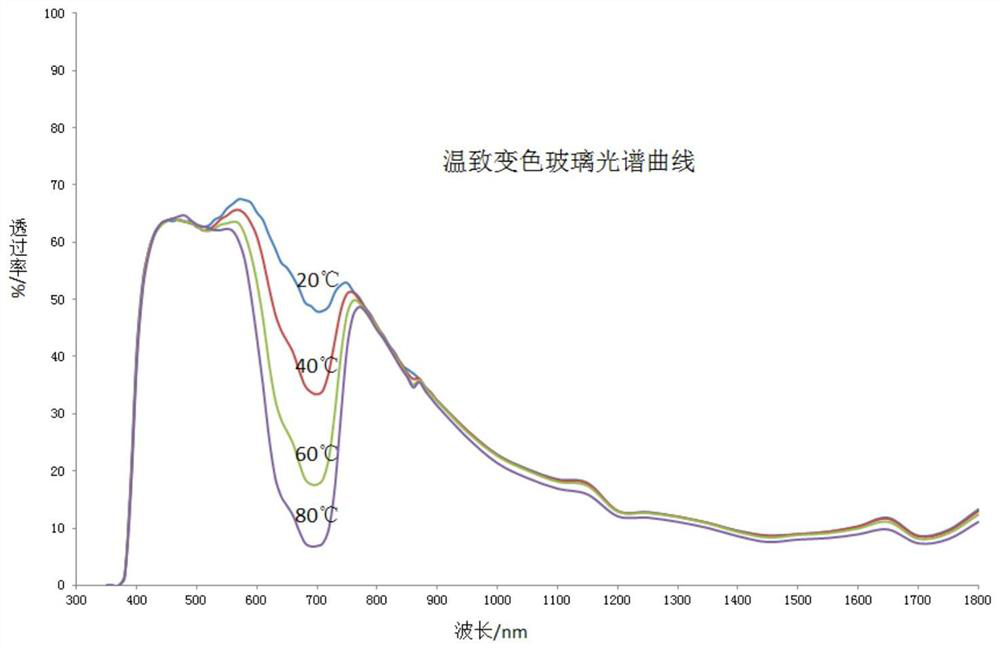

[0034] A thermochromic sheet, comprising 68.2 parts of PVB resin powder, 10 parts of discoloration auxiliary, 20 parts of triethylene glycol diisooctanoate, 0.2 part of nano-dispersion liquid containing indium tin oxide (ITO), and 0.6 part of antioxidant parts, UV-P 1.0 parts, the discoloration assistant includes Fe(II) phosphate and butanediol, and the weight parts of the two are 0.77 parts and 9.23 parts respectively. The antioxidants are tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propanoate]pentaerythritol (1010) and tris[2.4-di-tert-butylphenyl]phosphite (168) Mix in a 1:1 ratio. All components are blended and extruded to prepare a sheet, and then a 5mm ultra-white + 0.76mm thermochromic sheet + 5mm ultra-white laminated glass is made by the laminated glass production method. At different temperatures, the ultraviolet rays of the laminated glass are The transmittance, infrared transmittance and visible light transmittance were tested, and the results are shown in Ta...

Embodiment 2

[0039] A thermochromic sheet, comprising 60.2 parts of PVB resin powder, 18 parts of discoloration auxiliary, 20 parts of triethylene glycol diisooctanoate, 0.2 part of nano-dispersion liquid containing indium tin oxide (ITO), and 0.6 part of antioxidant parts, UV-P 1.0 parts, the discoloration assistant includes Fe(II) phosphate and butanediol, and the weight parts of the two are 1.38 parts and 16.62 parts respectively. The antioxidants are tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propanoate]pentaerythritol (1010) and tris[2.4-di-tert-butylphenyl]phosphite (168) Mix in a 1:1 ratio. All components are blended and extruded to prepare a sheet, and then a 5mm ultra-white + 0.76mm thermochromic sheet + 5mm ultra-white laminated glass is made by the laminated glass production method. At different temperatures, the ultraviolet rays of the laminated glass are The transmittance, infrared transmittance and visible light transmittance were tested, and the results are shown in T...

Embodiment 3

[0043] A thermochromic sheet, comprising 53.2 parts of PVB resin powder, 25 parts of discoloration auxiliary, 20 parts of triethylene glycol diisooctanoate, 0.2 part of nano-dispersion liquid containing indium tin oxide (ITO), and 0.6 part of antioxidant parts, UV-P 1.0 parts, the discoloration assistant includes Fe(II) phosphate and butanediol, and the weight parts of the two are 1.92 parts and 23.08 parts respectively. The antioxidants are tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propanoate]pentaerythritol (1010) and tris[2.4-di-tert-butylphenyl]phosphite (168) Mix in a 1:1 ratio. All components are blended and extruded to prepare a sheet, and then a 5mm ultra-white + 0.76mm thermochromic sheet + 5mm ultra-white laminated glass is made by the laminated glass production method. The light transmittance experiment was carried out, and the experimental results are shown in Table 3.

[0044] Table 3 embodiment three ultra-white laminated glass performance test results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com