Red anthraquinone compound and application thereof

A technology of anthraquinones and compounds, which is applied in the field of water-based polyurethane emulsion synthesis, to achieve obvious color rendering effect, improved performance, and stable color paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

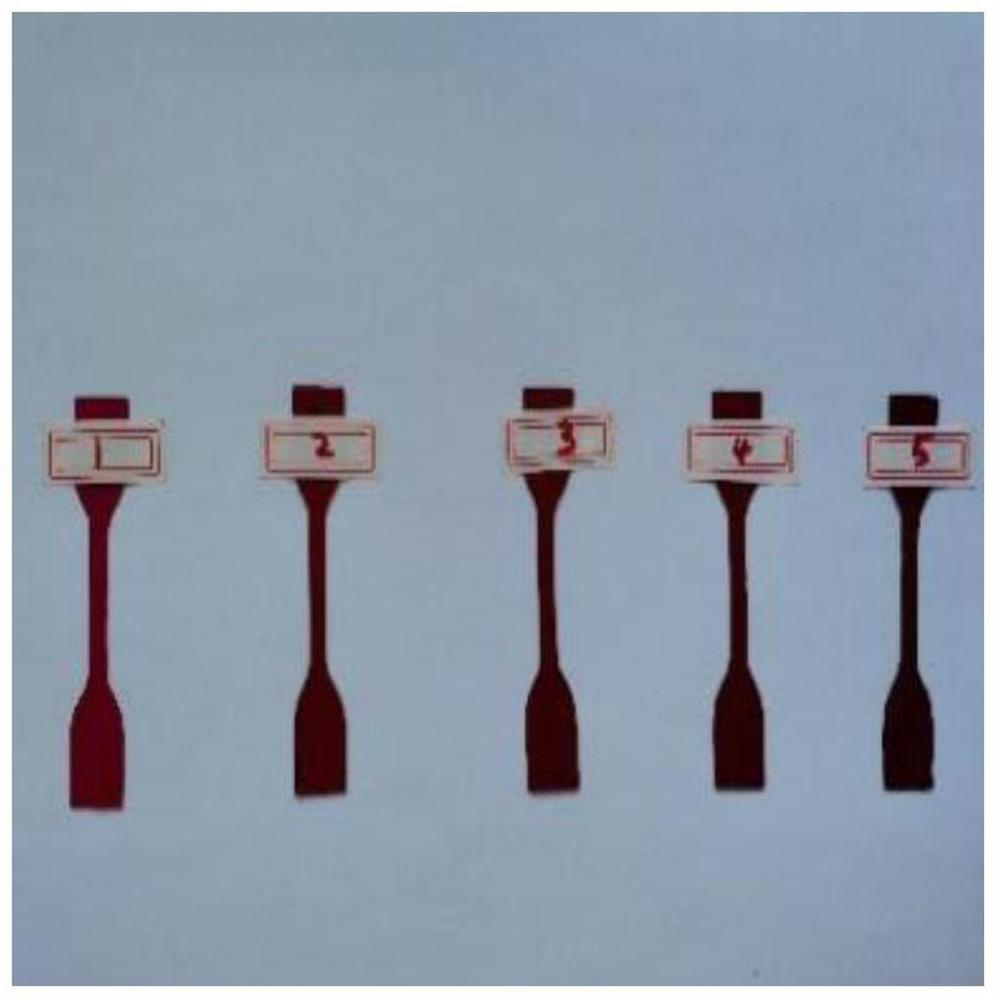

Image

Examples

preparation example Construction

[0026] Its preparation method comprises the following steps:

[0027] (1) Add 1,5-dichloroanthraquinone into a three-necked flask, slowly add 3-amino-1-propanol at room temperature, and stir to fully mix and dissolve it.

[0028] (2) After mixing and dissolving, continue to stir and start heating. After raising the temperature to 100-120°C, start constant temperature heating for 10-13h.

[0029] (3) After the reaction, add deionized water to wash the precipitate, and finally recrystallize to obtain the product.

[0030] The red water-based polyurethane color paste is prepared by using the red anthraquinone compounds provided by the present invention, and the present invention provides the following examples.

example 1

[0031] Example 1: Preparation of red water-based polyurethane color paste

[0032] 1. After the polytetrahydrofuran ether diol is decompressed to remove moisture, 20g and 14g of isophorone diisocyanate (IPDI) are weighed, added to the there-necked flask, heated to 85~90°C for reaction, the reaction system is fed with nitrogen protection React at 85~90℃ for 1~2h;

[0033] 2. Cool the reaction system obtained in step 1 to 60°C, dissolve 0.037g DYE-R and 1.94g 1,4-butanediol in a small amount of acetone, then add the reaction system, drop a drop of catalyst stannous octoate, and then heat up to 75 React at ~85℃ for 2~3h under nitrogen protection, add acetone during the reaction to adjust the viscosity, and adjust the viscosity of the reaction system to 15.0mPa·s-30mPa·s;

[0034] 3. Cool the reaction system in step 2 to 60°C, add 1.6g of 2,2-dimethylolbutyric acid, then add acetone to adjust the viscosity, adjust the viscosity of the reaction system to 15.0mPa·s-30mPa·s, and int...

Embodiment 2

[0037] Example 2: Preparation of red water-based polyurethane color paste

[0038] 1. After the polytetrahydrofuran ether diol is decompressed to remove moisture, 20g and 14g of isophorone diisocyanate (IPDI) are weighed, added to the there-necked flask, heated to 85~90°C for reaction, the reaction system is fed with nitrogen and protected at React at 85~90℃ for 1~2h;

[0039] 2. Cool down the reaction system in step 1 to 60°C, dissolve self-made 0.11g DYE-R and 1.92g 1,4-butanediol in a small amount of acetone, add the reaction system, then drop a drop of catalyst, and heat up to 75~85°C The reaction is carried out for 2 to 3 hours, and acetone is added to adjust the viscosity during the reaction, and the viscosity of the reaction system is adjusted to 15.0mPa·s-30mPa·s;

[0040] 3. Cool the reaction system in step 2 to 60°C, add 1.6g of 2,2-dimethylolbutyric acid, then add acetone to adjust the viscosity, introduce nitrogen protection and react at 75~85°C for 2~3h, the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com