Preparation method and application of cobalt-free positive electrode precursor material of lithium ion battery

A technology for lithium-ion batteries and lithium-rich cathode materials, which is applied in battery electrodes, positive electrodes, secondary batteries, etc., to avoid local segregation and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

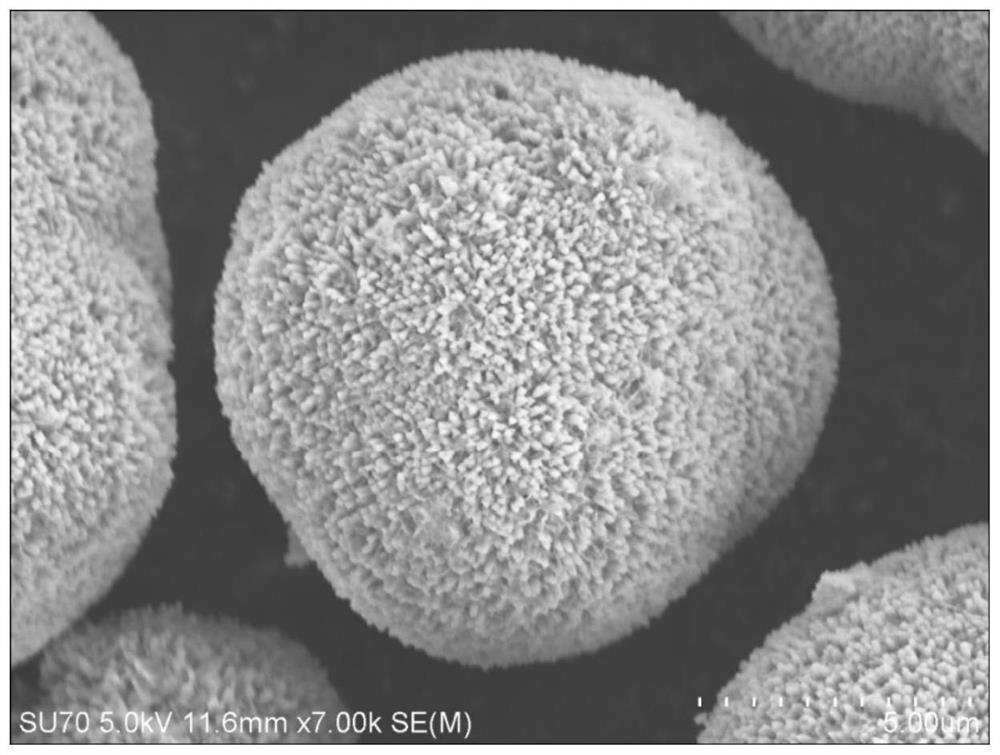

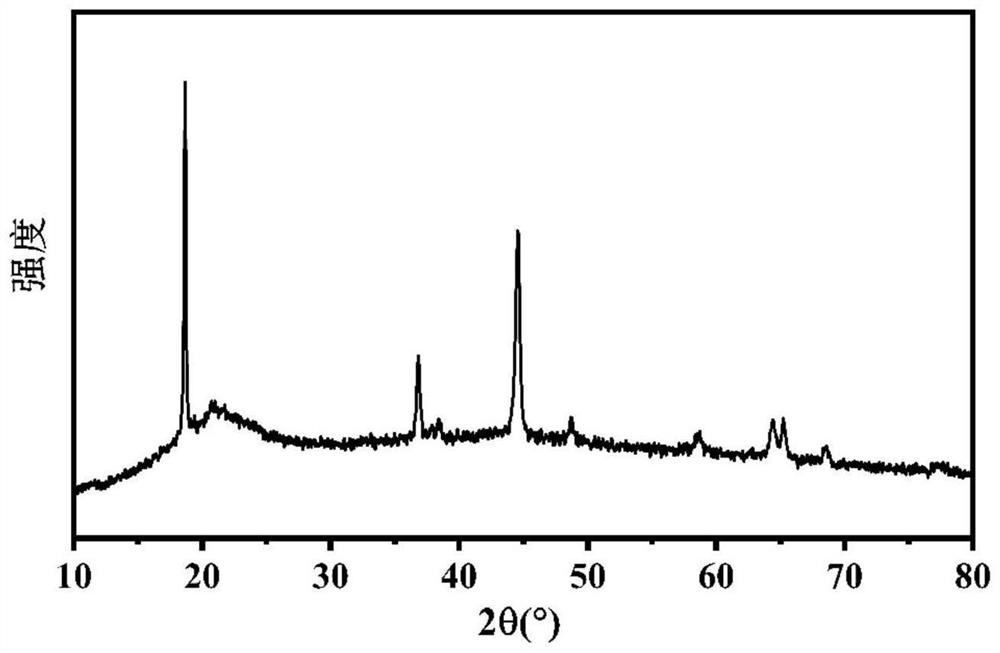

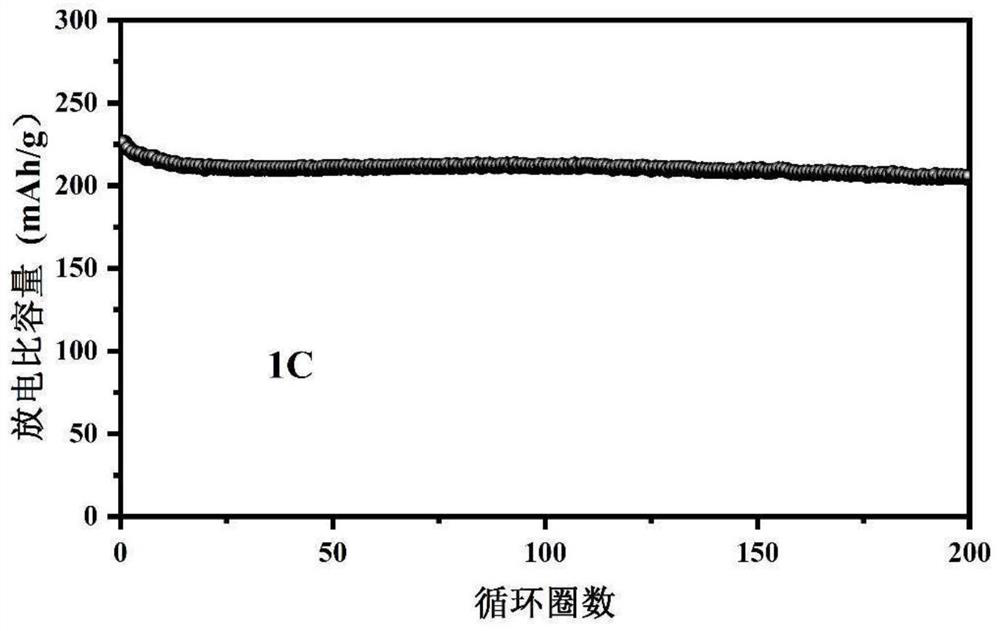

[0032] Manganese sulfate monohydrate (256.12g) and nickel sulfate hexahydrate (133.44g) whose molar ratio is Mn:Ni=3:1 are dissolved in deionized water to prepare a mixed metal salt solution of 1mol / L; sodium carbonate ( 212g) was dissolved in deionized water to prepare a 1 mol / L precipitant solution; sodium tartrate (4g) was dissolved in deionized water to prepare a complexing agent solution. Add the mixing of dilute sulfuric acid and tartaric acid to adjust the initial reaction solution pH to be 3.0, drop the prepared metal salt solution and precipitant solution into the reactor (10L) containing the complexing agent solution and deionized water (4L), stir The pump speed was 800 rpm / min, the reaction temperature was 60 °C, and the co-precipitation reaction was completed and then aged for 6 h. The precipitate was filtered and washed for 3 times, and then vacuum-dried at 60 °C for 24 h to obtain the precursor material. The dried precursor material was pre-calcined at 500 °C fo...

Embodiment 2

[0038] Dissolve manganese sulfate monohydrate (255.47g), nickel sulfate hexahydrate (133.42g), and ferrous sulfate heptahydrate (2.17g) with a molar ratio of Mn:Ni:Fe=197:65:1 in deionized water to prepare into a 1mol / L mixed metal salt solution; dissolving sodium carbonate (212g) in deionized water to prepare a 1mol / L precipitant solution; dissolving sodium tartrate (4g) in deionized water to prepare a complexing agent solution . Adding sulfuric acid or tartaric acid to adjust the initial reaction solution pH is 3.27, the prepared metal salt solution and the precipitant solution are dropped into the reactor (10L) equipped with the complexing agent solution, the stirring pump speed is 750rpm / min, and the reaction temperature is At 60°C, the co-precipitation reaction was completed and then aged for 5h. The precipitate was filtered and washed for 3 times, and then vacuum-dried at 60 °C for 24 h to obtain the precursor material. The dried precursor material was pre-calcined at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com