Method for connecting metal and carbon fiber composite material through electric activation-assisted ultrasonic waves

A composite material and ultrasonic technology, applied in metal processing equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of resin aging and short effective bonding time, and achieve the effect of promoting plastic flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

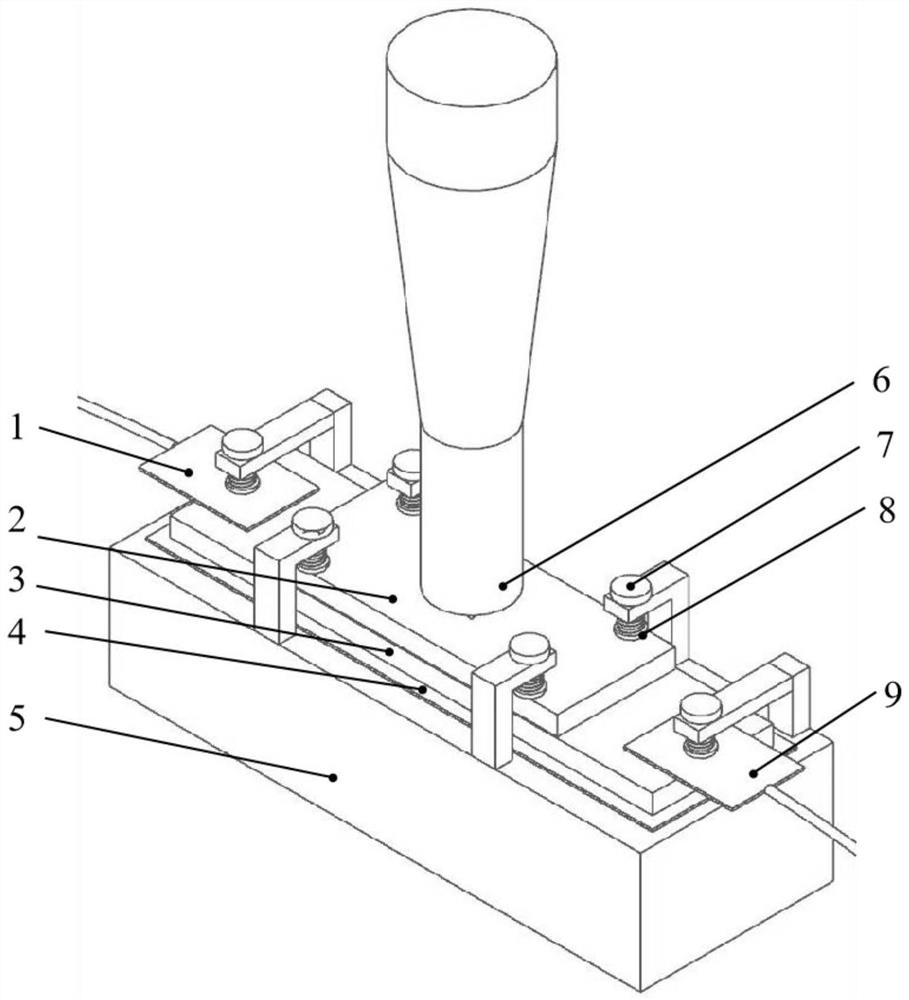

[0029] A method for connecting metal and carbon fiber composite materials by electro-activation assisted ultrasonic wave, comprising the following steps:

[0030] Step 1, perform surface treatment on the composite surface of carbon fiber composite material PEEK and magnesium alloy AZ31B;

[0031] Step 2, laying the metal plate after the surface treatment in step 1 on the insulating backing plate and fixing, and then placing the carbon fiber plate after the surface treatment in step 1 on the metal plate and fixing;

[0032] Step 3, connect and fix the copper electrode connected by the pulse power supply to both ends of the metal plate;

[0033] Step 4, applying a pulse current to the metal plate, the current is 80A, the frequency is 500Hz, the duty cycle is 60%, and the surface temperature of the metal plate is monitored at the same time;

[0034] Step 5: Perform ultrasonic spot welding. During the welding process, the power of the ultrasonic vibration system is 4000W, the vib...

Embodiment 2

[0036] A method for connecting metal and carbon fiber composite materials by electro-activation assisted ultrasonic wave, comprising the following steps:

[0037] Step 1, surface treatment is performed on the carbon fiber composite material PEEK and the aluminum alloy 5052 composite surface;

[0038] Step 2, laying the metal plate after the surface treatment in step 1 on the insulating backing plate and fixing, and then placing the carbon fiber plate after the surface treatment in step 1 on the metal plate and fixing;

[0039] Step 3, connect and fix the copper electrode connected by the pulse power supply to both ends of the metal plate;

[0040] Step 4, applying pulse current to the metal plate, the current is 50A, the frequency is 600Hz, the duty cycle is 50%, and the surface temperature of the metal plate is monitored at the same time;

[0041] Step 5: Perform ultrasonic spot welding. During the welding process, the power of the ultrasonic vibration system is 4000W, the v...

Embodiment 3

[0043] A method for connecting metal and carbon fiber composite materials by electro-activation assisted ultrasonic wave, comprising the following steps:

[0044] Step 1, surface treatment of carbon fiber composite material PA6 and stainless steel SS304 composite surface;

[0045] Step 2, laying the metal plate after the surface treatment in step 1 on the insulating backing plate and fixing, and then placing the carbon fiber plate after the surface treatment in step 1 on the metal plate and fixing;

[0046] Step 3, connect and fix the copper electrode connected by the pulse power supply to both ends of the metal plate;

[0047] Step 4, applying pulse current to the metal plate, the current is 100A, the frequency is 1200Hz, the duty ratio is 70%, and the surface temperature of the metal plate is monitored at the same time;

[0048] Step 5, ultrasonic spot welding is performed. During the welding process, the power of the ultrasonic vibration system is 4000W, the vibration freq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com