Application of high-sulfur coal and method for recycling Au (S2O3) 23-by using roasted product of high-sulfur coal

A technology for roasting products and high-sulfur coal, applied in chemical instruments and methods, alkali metal oxides/hydroxides, and other chemical processes, can solve problems that threaten life and property safety, farmland heavy metal pollution, and air pollution, and achieve The preparation process is simple, the environment is friendly, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

(1) Take the original high-sulfur coal for crushing and grinding, sieve into 200-mesh samples and dry at 70 °C;

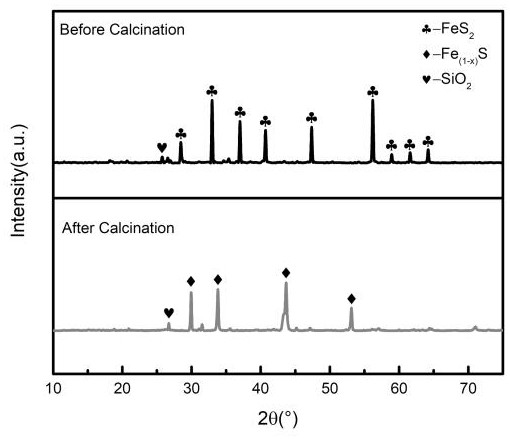

(2) Put a corundum boat in the tube resistance furnace, pour 10g of weighed high-sulfur coal powder, and roast the high-sulfur coal at 1000°C for 2h in a nitrogen atmosphere.

[0020] Take four 0.5g roasted high-sulfur coals prepared in this example and add them to 100 mL containing Au(S) respectively. 2 O 3 ) 2 3- In the solution, Au(S 2 O 3 ) 2 3- The concentration of Au (S 2 O 3 ) 2 3- The adsorption rate reached 80%.

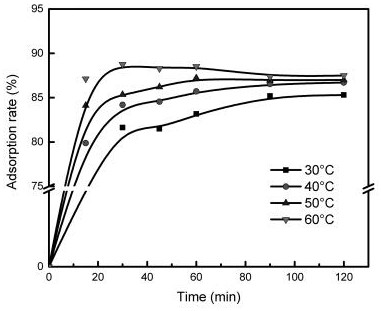

[0021] from figure 1 It can be seen that with the increase of temperature, the loading of gold complex ions by high-sulfur coal also increases, indicating that the experiment in a higher temperature environment is more conducive to the progress of adsorption and the improvement of equilibrium adsorption capacity. In the first 30 minutes, the adsorption efficiency increased rapidly, reaching more than 80%, and then th...

Embodiment 2

Embodiment 3

[0028] Get 0.5g of roasting high-sulfur coal prepared in this example and add it to 100mL containing Au (S 2 O 3 ) 2 3- In the solution, Au(S 2 O 3 ) 2 3- The concentration of Au(S) was 80 ppm, the pH value of the solution was adjusted to 10, and the temperature was 2 O 3 ) 2 3- The adsorption rate reached 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com