UV curing pressure-sensitive adhesive and preparation method thereof

A technology of curing pressure and polybasic acid, which is applied in the field of pressure-sensitive adhesives, can solve the problems of pressure-sensitive adhesive pollution and other problems, and achieve the effects of small environmental pollution, low energy consumption, and improved cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

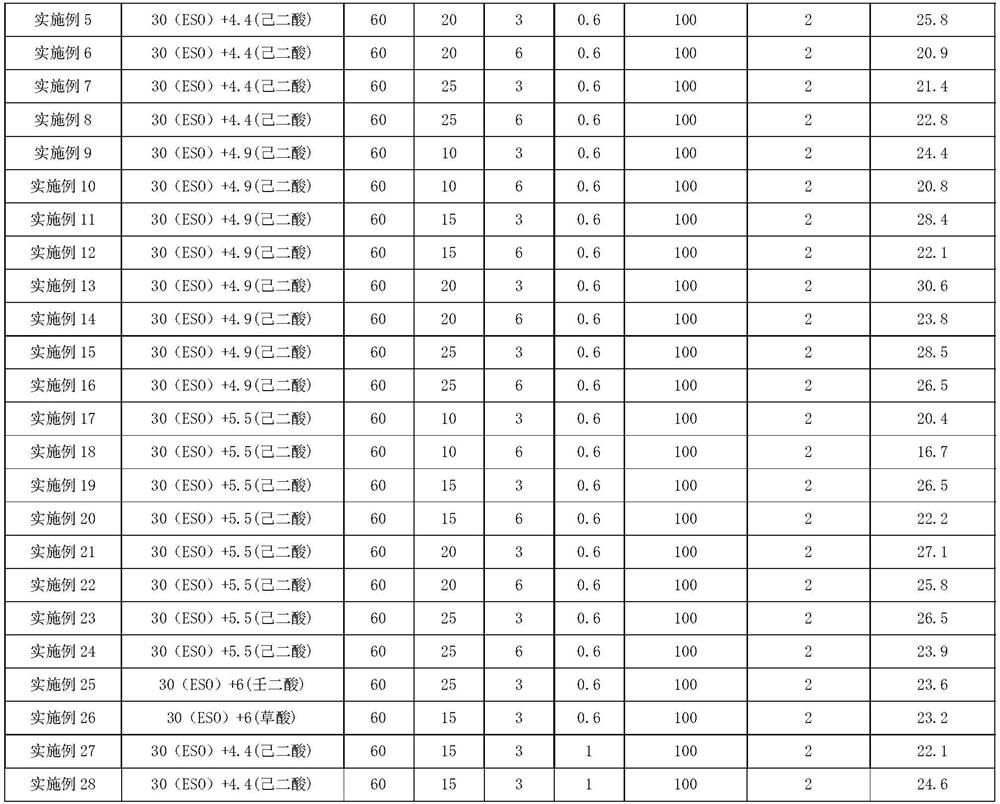

Examples

Embodiment 1

[0023] The UV-curable pressure-sensitive adhesive of this embodiment is formed by ultraviolet light curing of a composition comprising the following components: 34.4 parts by weight of epoxy soybean oil (ESO)-adipic acid intermediate (30 parts by weight of epoxy soybean oil, 4.4 parts by weight of adipic acid), 60 parts by weight of isooctyl acrylate (2-EHA), 10 parts by weight of acrylic acid (AA), 3 parts by weight of hydroxyethyl acrylate (HEA) and 0.6 parts by weight of 1173 photoinitiator.

[0024] The preparation method of the UV curing pressure-sensitive adhesive of the present embodiment comprises the following steps:

[0025] (1) Preparation of epoxy soybean oil-polyacid intermediate: by epoxy soybean oil (ESO) 30 weight parts, adipic acid 4.4 weight parts, epoxy soybean oil, adipic acid are mixed and stirred and heated, and the temperature is set at 180 ℃, stop heating after reaching the reaction temperature for 6 minutes, and cool to obtain the epoxidized soybean oi...

Embodiment 2

[0030] The UV-curable pressure-sensitive adhesive of this example is formed by UV-curing a composition similar to that of Example 1, except that the amount of hydroxyethyl acrylate used in the composition of this example is 6 parts by weight.

[0031] The preparation method of the UV-curable pressure-sensitive adhesive of this embodiment is the same as that of Embodiment 1 except for the amount of hydroxyethyl acrylate added.

[0032] For the preservation of the UV-cured pressure-sensitive adhesive strips in this embodiment, the 180° peel strength of the adhesive strips was tested on an electronic tensile machine according to the GB / T 2792-2014 standard. The test results are shown in Table 1.

Embodiment 3

[0034] The UV-curable pressure-sensitive adhesive of this example is formed by curing a composition similar to that of Example 1 through ultraviolet light, except that the amount of acrylic acid used in the composition of this example is 15 parts by weight.

[0035] The preparation method of the UV-curable pressure-sensitive adhesive of this embodiment is the same as that of Embodiment 1 except for the amount of acrylic acid added.

[0036] For the preservation of the UV-cured pressure-sensitive adhesive strips in this embodiment, the 180° peel strength of the adhesive strips was tested on an electronic tensile machine according to the GB / T 2792-2014 standard. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com