High-thermal-conductivity self-repairing thermal interface material and preparation method thereof

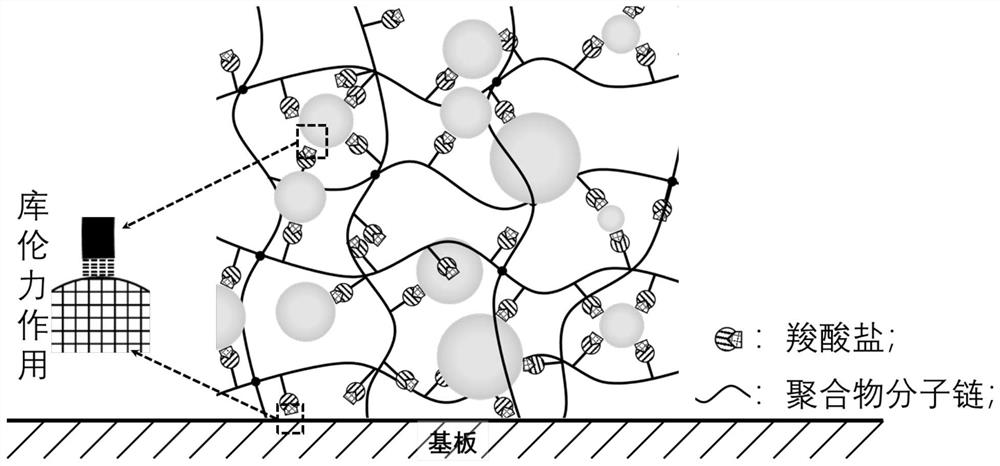

A thermal interface material and self-healing technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve problems such as cracks, damage and heat dissipation, and achieve high thermal conductivity, improve dispersion, and increase thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

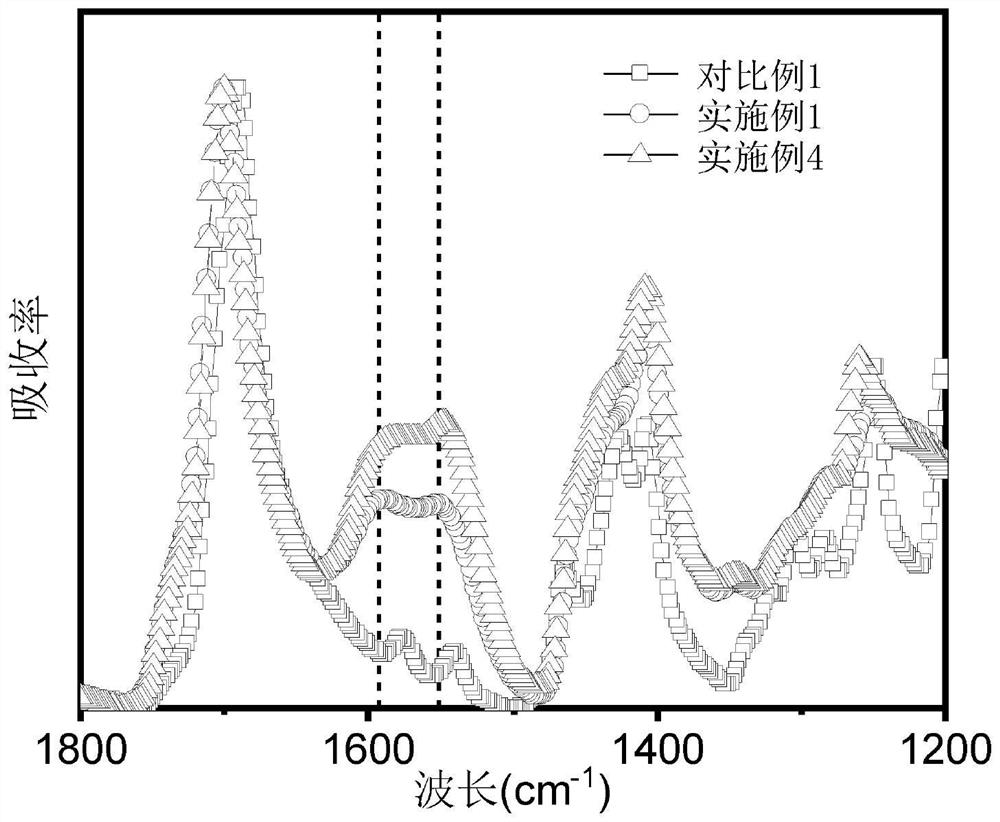

Embodiment 1

[0056] (1) the aluminum powder (78.4g) of particle diameter 20um, the zinc oxide (3.6g) of particle diameter 2um are stirred at 1000rpm rotating speed in planetary mixer for 10min, then take out blended aluminum powder / zinc oxide for subsequent use;

[0057] (2) the temperature of reaction was increased to 150°C, 30g of lipoic acid was added to the round-bottomed flask equipped with a mechanical stirring device, a reflux condenser and an inert protection device, and then the above-mentioned blended aluminum powder / zinc oxide filler and 0.18g were added successively. N,N'-methylenebisacrylamide, and stirring for 10min to obtain a thermally conductive elastomer;

[0058] (3) Pour the mixture obtained in step (2) into polytetrafluoroethylene molds of different sizes, cool and demold, and obtain samples of different sizes for later use.

Embodiment 2

[0060] Except that in step (1), the aluminum powder (78.4g) with a particle size of 20um and zinc oxide with a particle size of 2um (3.6g) were replaced with aluminum powder (84g) with a particle size of 20um and zinc oxide (6g) with a particle size of 2um. All are the same as Example 1.

Embodiment 3

[0062] In step (1), aluminum powder (78.4g) with a particle size of 20um and zinc oxide with a particle size of 2um (3.6g) were replaced with aluminum powder with a particle size of 20um (89.6g) and zinc oxide with a particle size of 2um (8.4g) , and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com