Building stone machining device through saw cutting

A processing device and sawing device technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of water waste and failure to turn off water supply in time, and achieve cleanliness, reduce adhesion residue, and save water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

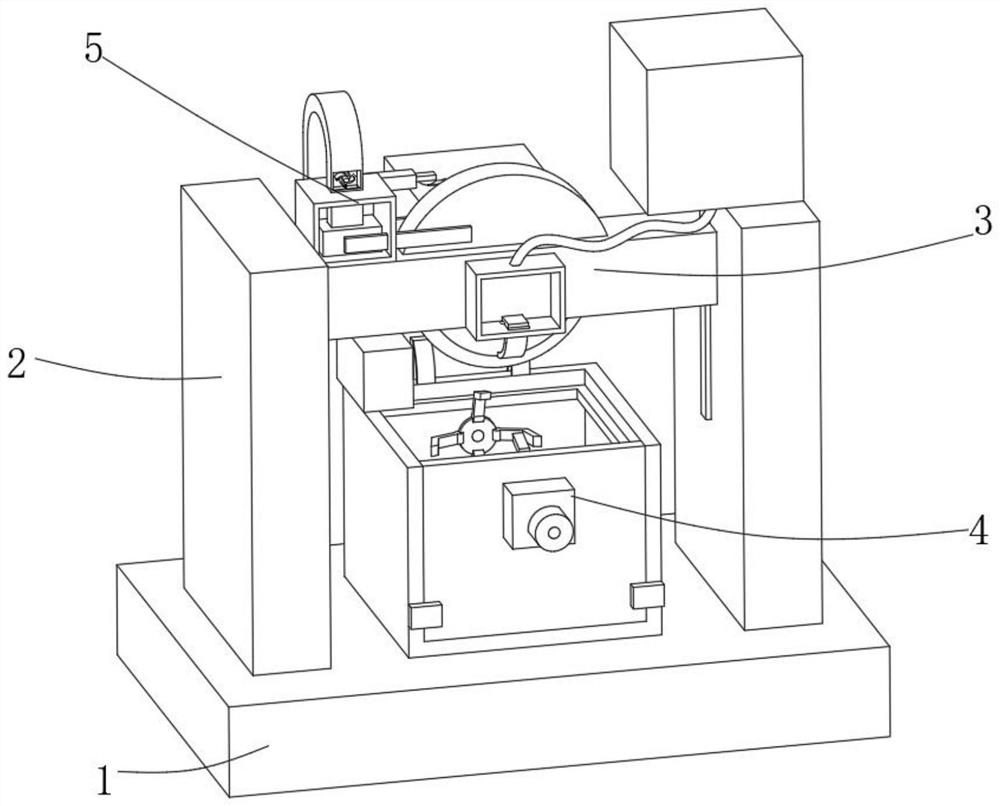

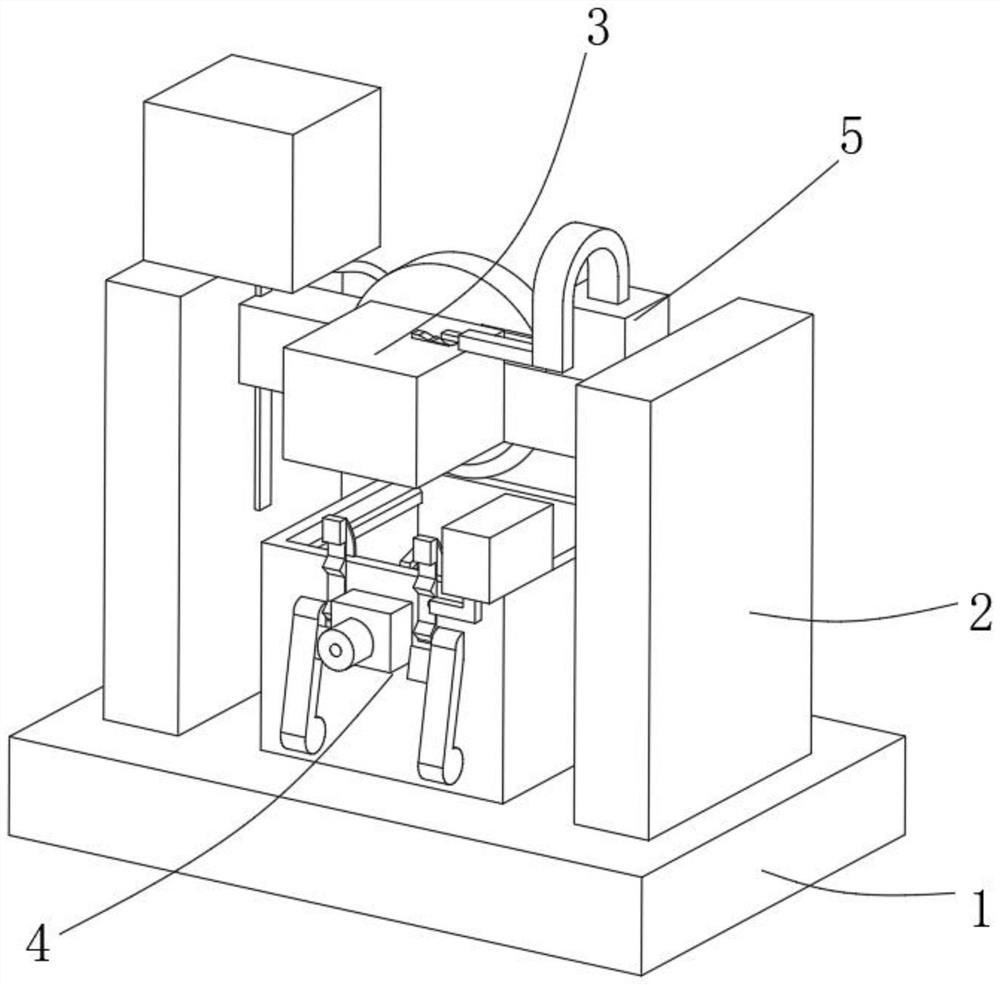

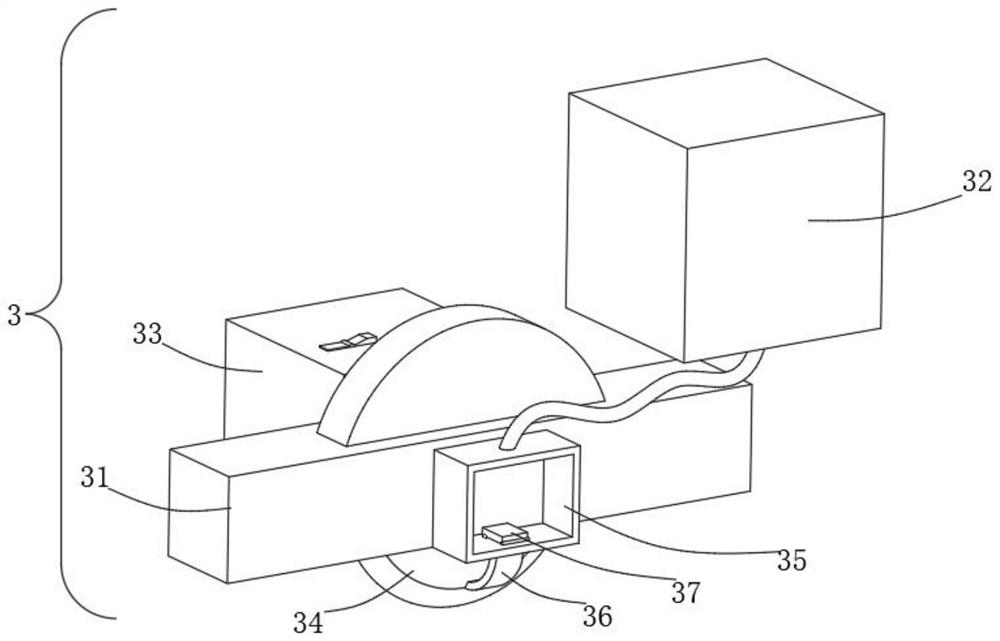

[0030] see Figure 1-9 , the present invention provides a technical solution: a construction stone processing device by sawing, comprising a base 1, two support plates 2 are symmetrically fixed on both sides of the upper surface of the base 1, and the two support plates 2 are slidably connected There is a sawing device 3. The sawing device 3 includes a cross bar 31 and a water storage tank 1 32. The two sides of the cross bar 31 are respectively slidably connected with the two bracket plates 2. The back of the cross bar 31 is fixed with a motor 33. A control switch 2 is provided, the inside of the crossbar 31 is connected with a cutting saw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap