Processing preparation system for blending cigarette sheets

A preparation system and sheet technology, which is applied in the preparation of tobacco, tobacco, conveyor control devices, etc., can solve the problem of loose and poor core wrapping of tobacco sheets and sheets, failure to ensure consistent ratio of turnover boxes, uneven premixing of sheets and tobacco leaves, etc. problems, to achieve the effect of ensuring stability and temperature uniformity, ensuring product quality, and reducing the extreme difference in moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

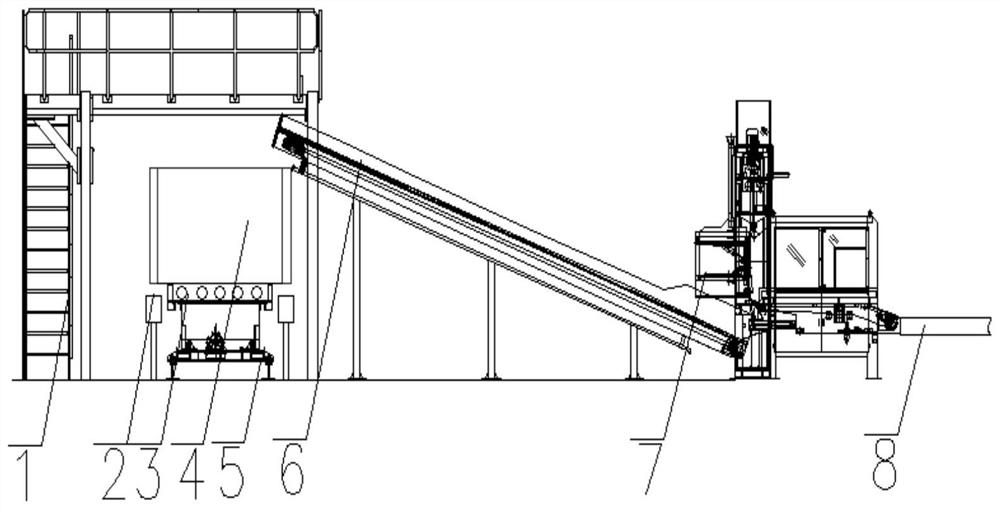

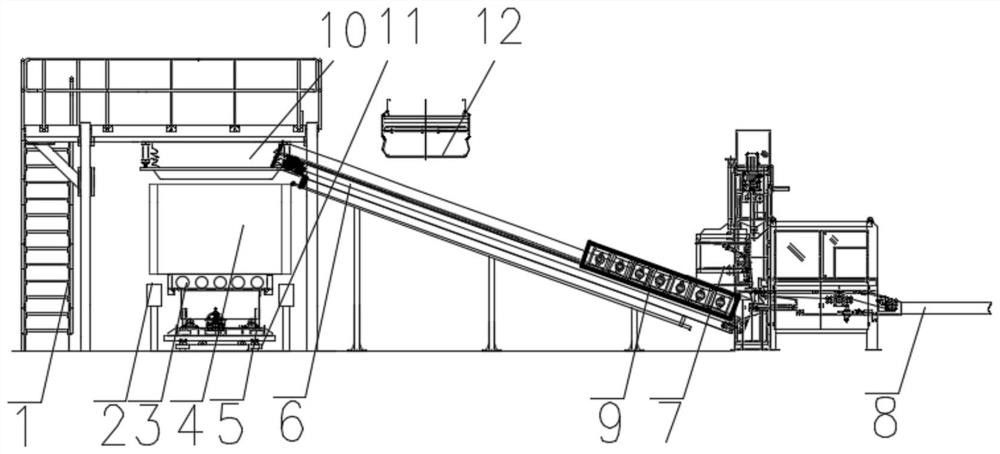

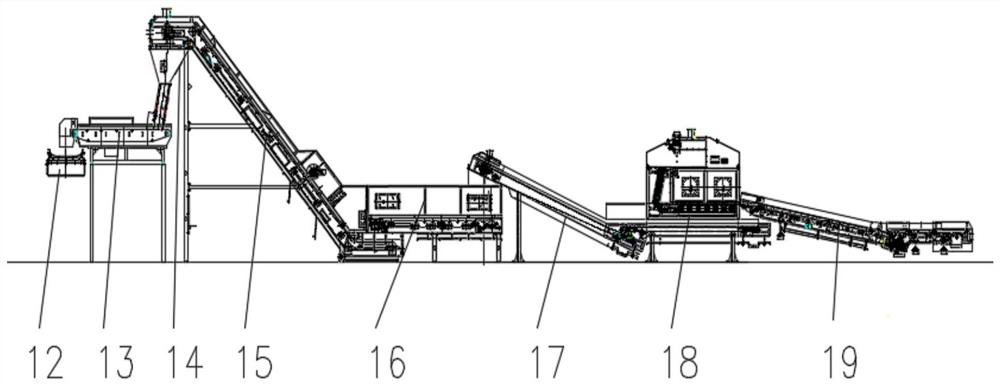

[0040] Below in conjunction with the accompanying drawings in the embodiments of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely

[0053]

[0066] Optionally, the lifting base 5 is installed on the floor scale 11, and the floor scale 11 weighs the object on the lifting base 5. lift

[0078] The receiving cylinder extends into the opening of the turnover box 4 to ensure that all the materials through the receiving barrel enter the opening of the turnover box 4,

[0079] Preferably, the material of the fixing frame is white steel, which is not easy to corrode and has a longer service life.

[0087] The main material conveying belt 6 and the blending belt 12 are associated with each other, and start and stop synchronously according to the output signal of the floor scale 11. cut

[0088] The various embodiments in this specification are described in a progressive manner, and what each embodiment focuses on is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com