Antimicrobial particles

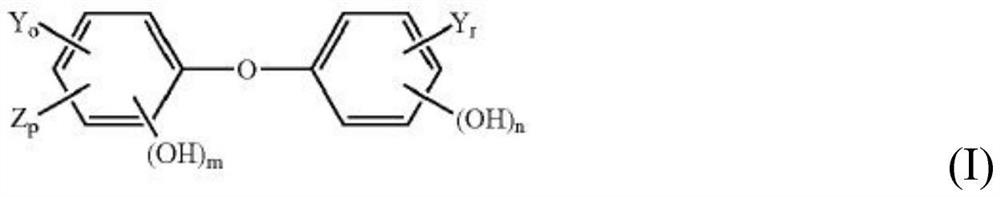

A technology of anti-microbial and anti-microbial agents, applied in the direction of chemicals, biocides, animal repellants, etc. for biological control, can solve the problems of poor anti-microbial efficacy, high use cost, disappointment, etc., and achieve high anti-microbial Effects of Efficacy, Increased Deposition Rate, Efficient Delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0090] Preparation of antimicrobial particles

[0091] For supports that can be conveniently processed as a melt, a rotational molding process can be used. The mixture of molten carrier and other materials making up the particles is prepared, for example, in a batch or continuous mixing process. The molten mixture can be pumped to a rotary forming machine, such as a Sandvik ROTOFORM 3000 with a 750mm wide, 10m long belt. The rotary forming apparatus may have a rotating cylinder. The cylinder may have 2mm diameter holes arranged at 10mm spacing in the transverse direction and 9.35mm spacing in the longitudinal direction. The cylinder may be positioned approximately 3mm above the belt. The belt speed and the rotation speed of the drum can be set to about 10 m / min. The molten mixture can pass through holes in the rotating drum and be deposited on a moving conveyor positioned below the rotating drum.

[0092] The molten mixture may be cooled on a moving conveyor to form a p...

Embodiment 1

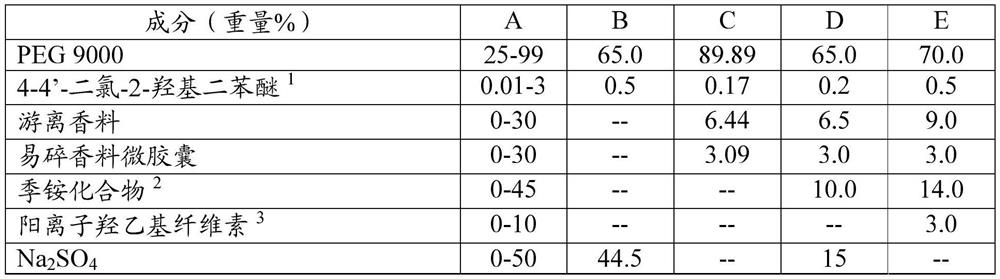

[0121] Example 1: Antimicrobial particles

[0122] The following are exemplary antimicrobial particles A-E according to the present invention:

[0123] Table 1

[0124]

[0125]

[0126] 1 by trade name HP100, supplied by BASF, contains 30% 4-4'-dichloro-2-hydroxydiphenyl ether active in 1,2-propanediol solution. Concentrations provided herein are pure active levels, not raw material levels.

[0127] 2 C18 unsaturated DEEHMAMS (diethyl ester hydroxyethyl methyl ammonium methyl methyl sulfate), available from EVONIK, has an iodine number of about 42.

[0128] 3 Polymer PK, available from Dow Chemical, is a cationic hydroxyethyl cellulose with a weight average molecular weight of 400 kDa, a charge density of 0.18 and an average weight percent nitrogen / anhydroglucose repeat unit of 0.28%.

Embodiment 2

[0129] Example 2: Antimicrobial particles in granular laundry detergent products

[0130] The antimicrobial particles of the present invention from Example 1 were incorporated into the following granular laundry detergent products of Formulations I-V:

[0131] Table 2

[0132] Composition (wt%) I II III IV C 11 -C 13 Linear Alkylbenzene Sulfonate (LAS)

[0133] 1 Any of the antimicrobial beads A-E of the invention from Example 1 or mixtures thereof.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com