Circuit board with stepped blind holes

A ladder type, circuit board technology, applied in printed circuit, printed circuit manufacturing, printed circuit components, etc., can solve the problem that the working heat of the circuit board is easily piled up at the cross-linking place of the blind hole, the smooth surface of the circuit layer has insufficient impact resistance, Lack of circuit board substrate installation and adaptation capabilities to achieve the effect of improving assembly safety, improving relative physical strength, and ensuring installation and adaptation capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

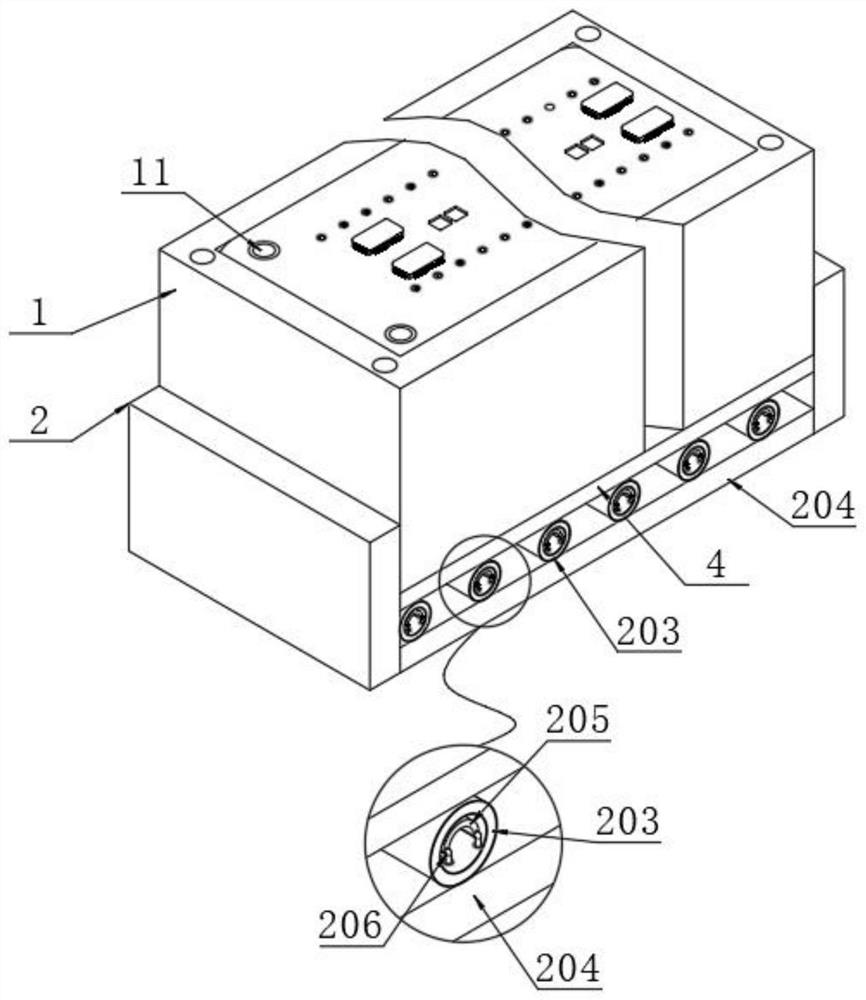

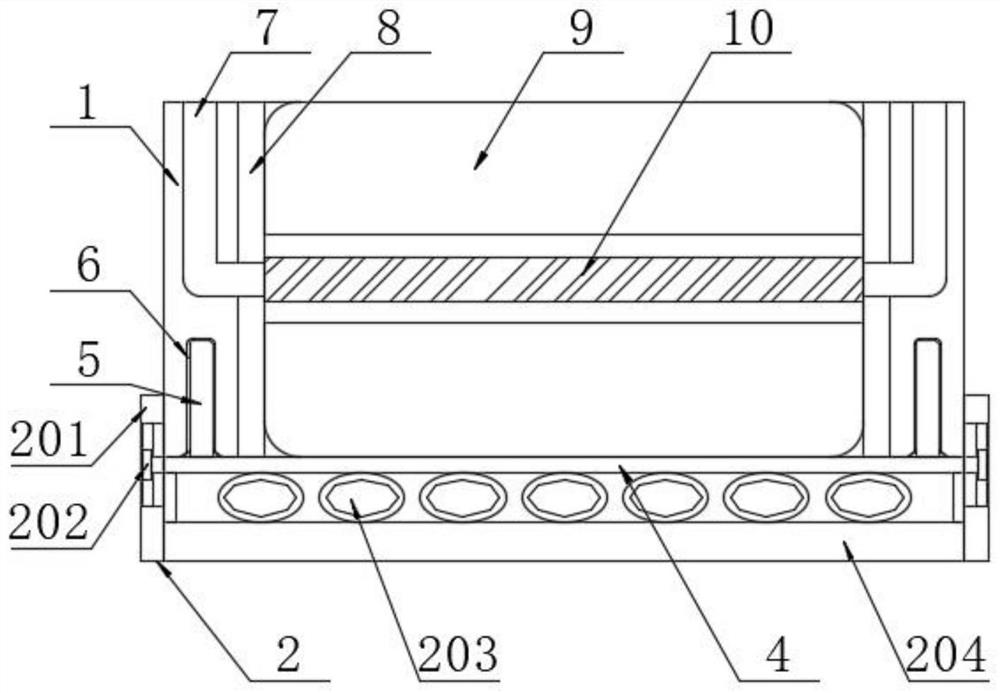

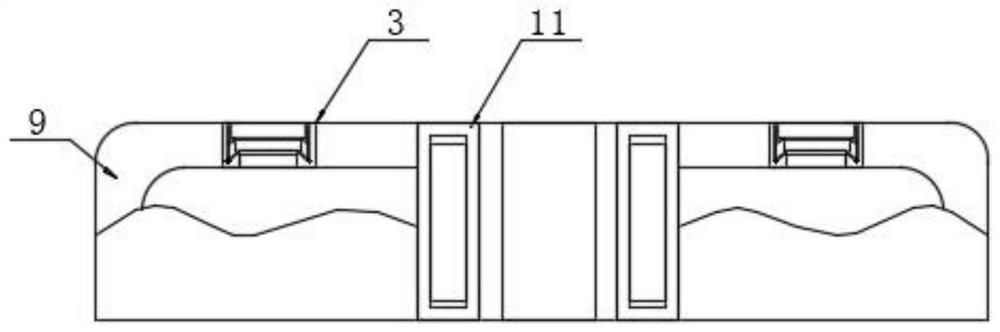

[0046] see Figure 1-7 As shown, the present invention provides a technical solution: a circuit board with stepped blind holes, comprising a circuit board main body 9 and an movably connected fixing frame 1 , the top of the circuit board main body 9 is provided with a number of stepped blind holes by laser. The blind hole mechanism 3, and the inner cavity of the stepped blind hole mechanism 3 is provided with a drainage channel 302, and the inner cavity of the stepped blind hole mechanism 3 is provided with a tapered groove 305, and the tapered groove 305 is coated with modified paint, The top of the circuit board main body 9 is embedded with a plurality of assembly sets 11 , the blind hole mechanism 3 includes a blind hole seat 301 , the blind hole seat 301 is cast on the top of the circuit board main body 9 , and the inner cavity of the blind hole seat 301 is punched and opened. There are three stepped holes 304, and the blind hole seat 301 has a tapered groove 305, and the ...

Embodiment 2

[0049] like Figure 5 As shown, the difference from Embodiment 1 is that the blind hole mechanism 3 includes a blind hole seat 301, and the inner cavity of the blind hole seat 301 is sequentially sleeved with three hole cavity sleeves 306 from top to bottom, and the blind hole seat Both sides of the top of 301 are provided with drainage channels 302, and the drainage channels 302 communicate with the corresponding position hole sleeve 306 through the branch hole 303, and the built-in diameter of the hole sleeve 306 decreases sequentially from top to bottom, and the hole sleeve 306 The inner cavity is coated with modified paint.

[0050] The specific embodiment is as follows: this embodiment mainly realizes the pre-assembly of the blind hole seat 301 through three mutually nested cavity sleeves 306, thereby effectively improving the assembly accuracy of the cavity sleeve 306 and realizing the size of the cavity sleeve 306. It can be prepared to meet the production and assembly...

Embodiment 3

[0052] like Figure 1-3 As shown in FIG. 6, a circuit board containing stepped blind holes includes a circuit board body 9 and a movably connected fixing frame 1. A number of stepped blind hole mechanisms 3 are opened on the top of the top of the circuit board body 9 by laser, and The inner cavity of the stepped blind hole mechanism 3 is provided with a drainage channel 302, and the inner cavity of the stepped blind hole mechanism 3 is provided with a tapered groove 305, and the tapered groove 305 is coated with modified paint, and the circuit board main body 9 A number of assembling sets 11 are embedded on the top, and an assembling mechanism 2 is slidably connected to the bottom of the fixing frame 1. The assembling mechanism 2 includes a sliding seat 201, one side of the sliding seat 201 is in contact with one side of the fixing frame 1, and the A sliding slot is provided on one side of the sliding seat 201, and a sliding block 202 is slidably connected in the sliding slot,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com