Open type double-column fixed type press machine for punching processing of anchoring ratchet wheel base of contact network

A catenary and anchor ratchet technology, which is applied in the field of presses, can solve the problems of reducing material processing accuracy, reducing pressure and use safety, shaking and offsetting, etc., and achieves the effects of improving processing efficiency, improving safety, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

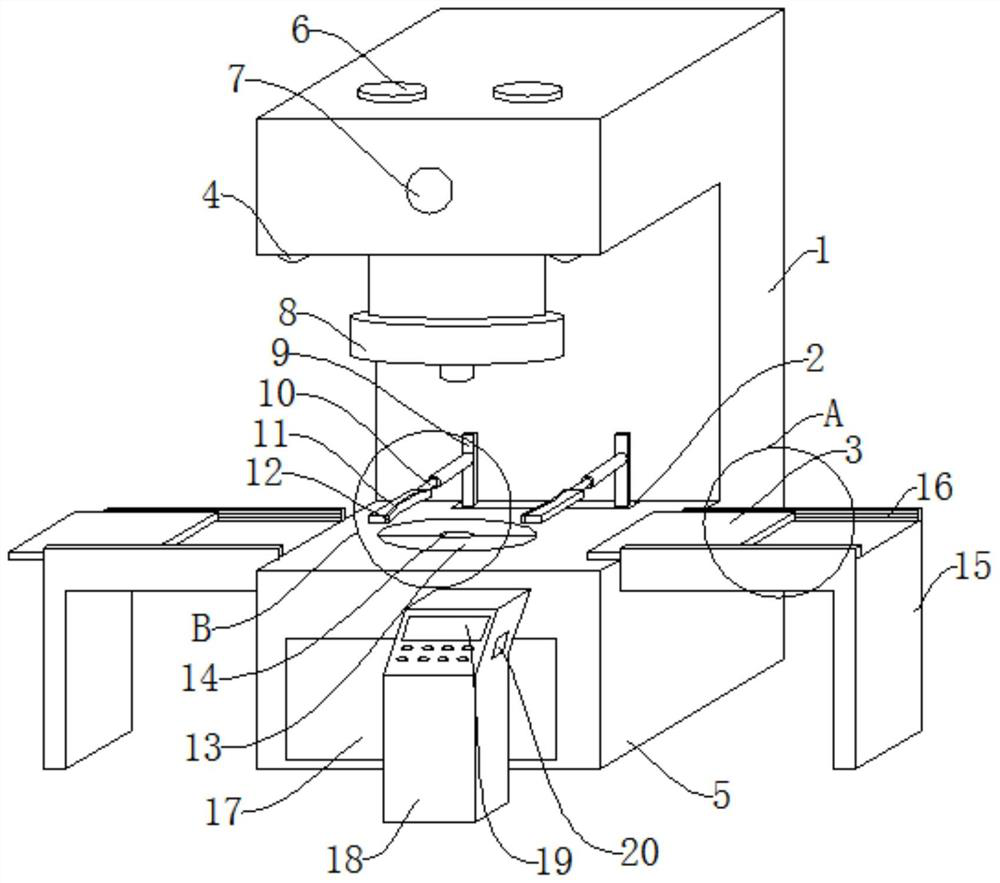

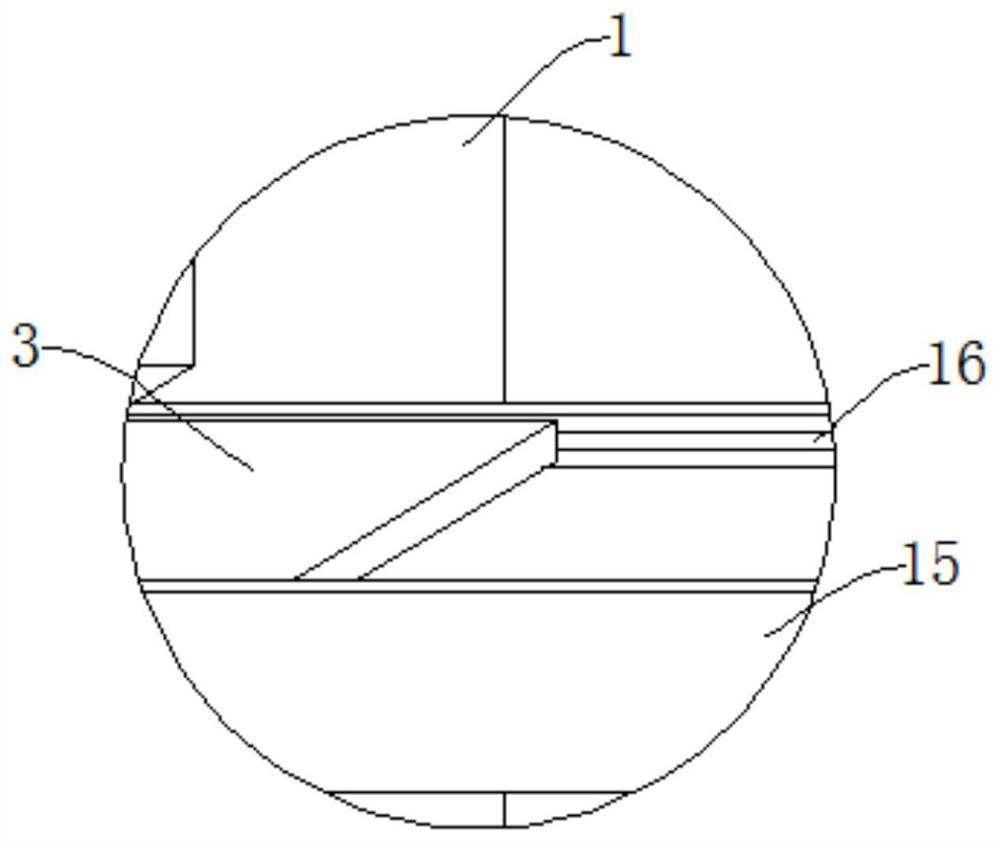

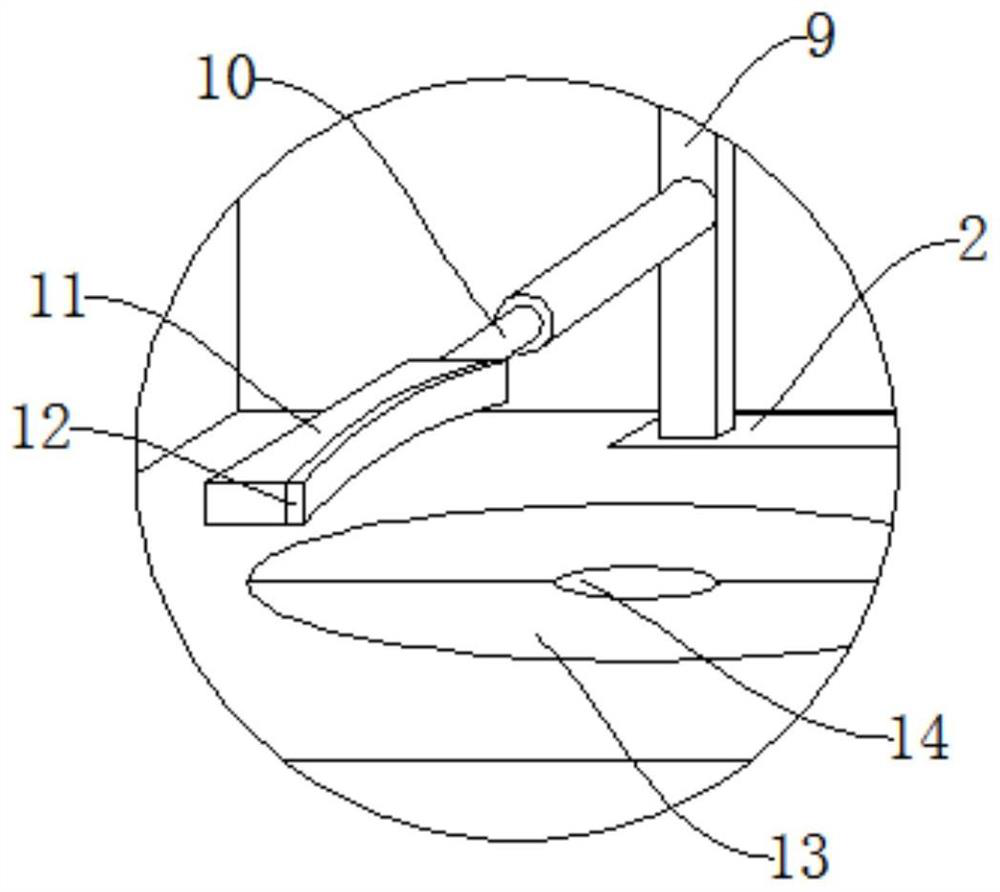

[0038] Such as Figure 1-Figure 4 As shown, the open double-column fixed press for punching the anchor ratchet base of the catenary includes a body 1, an electric sliding table 2 and a material plate 3, the bottom of the body 1 is provided with a base 5, and the base 5 A waste box 17 is installed on the top, an alarm 7 is arranged on the side wall of the body 1, two hydraulic presses 6 are installed on the top side of the body 1, and a stamping seat 8 is provided at the bottom end of the hydraulic press 6. Two human body sensors 4 are symmetrically arranged on the bottom end of one side of the body 1, and the human body sensor 4 can automatically detect whether there are people in the working area. Holes 14, the electric slide table 2 is arranged on one side of the deck 13, and two electric slide rails 9 are installed on the electric slide table 2, and the electric slide t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com