Monolithic heterogeneous integrated structure of top-layer p-type diamond MOSFET and GaN HEMT and preparation method of monolithic heterogeneous integrated structure

A diamond and diamond layer technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve problems such as electrical performance degradation, failure, and heat dissipation performance that cannot meet the application of GaN effect transistors. The effect of junction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below with reference to specific embodiments, but the embodiments of the present invention are not limited thereto.

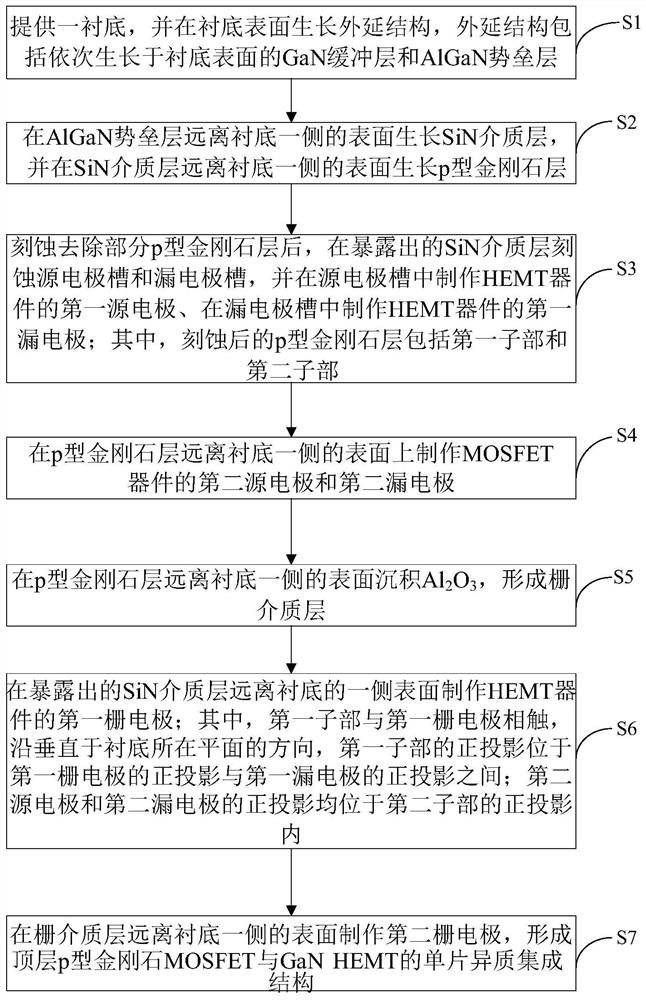

[0038] figure 1 It is a flow chart of the preparation method of the monolithic hetero-integrated structure of the top p-type diamond MOSFET and GaN HEMT provided by the embodiment of the present invention, Figure 2-9 It is a schematic diagram of the preparation method of the monolithic hetero-integrated structure of the top layer p-type diamond MOSFET and GaN HEMT provided by the embodiment of the present invention. See Figure 1-9 , an embodiment of the present invention provides a method for preparing a monolithic hetero-integrated structure of a top p-type diamond MOSFET and a GaN HEMT, including:

[0039] S1, providing a substrate, and growing an epitaxial structure on the surface of the substrate, the epitaxial structure including a GaN buffer layer and an AlGaN barrier layer sequentially ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com