Evaporation-boiling longitudinal coexistence composite structure for enhancing boiling heat transfer

A composite structure and enhanced boiling technology, applied in indirect heat exchangers, lighting and heating equipment, semiconductor devices, etc., can solve problems such as occupation, achieve heat transfer area expansion, strengthen disturbance, improve heat transfer performance and critical heat flux density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

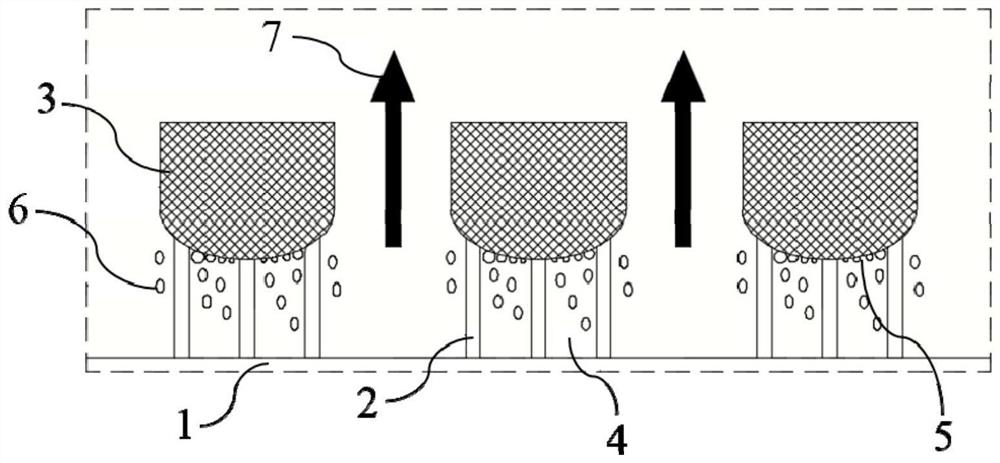

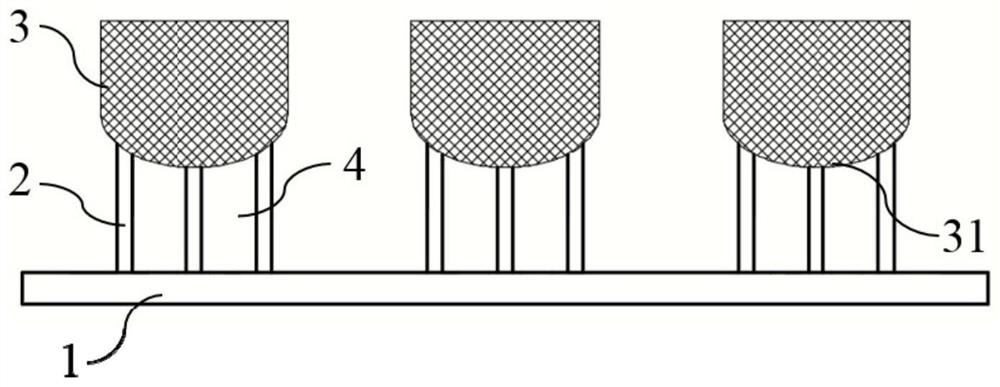

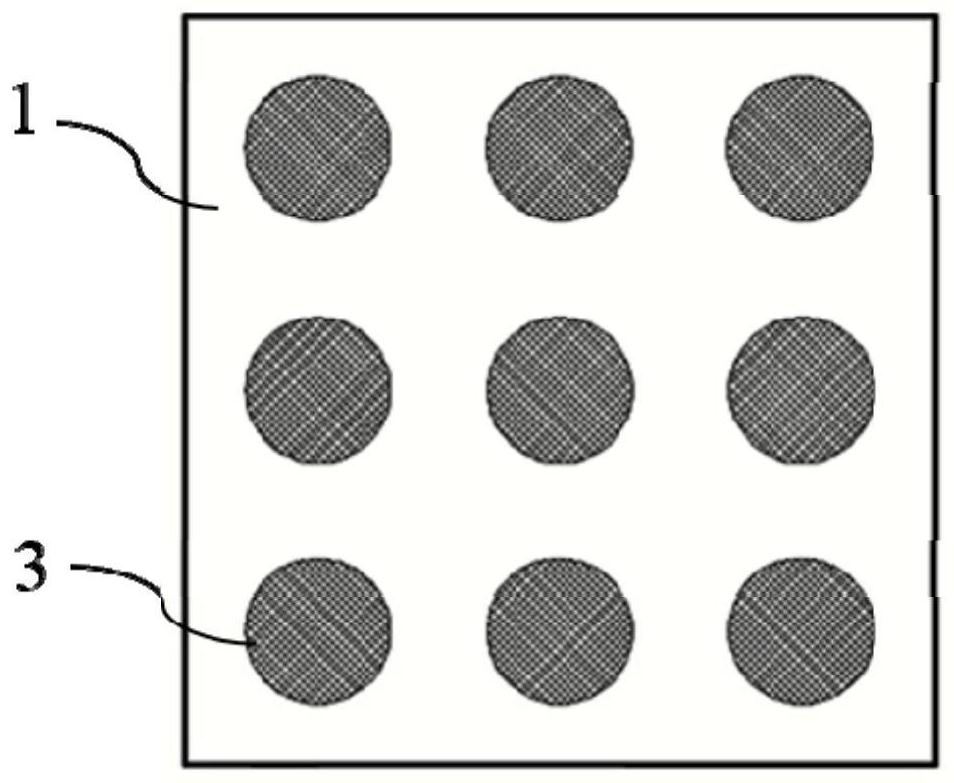

[0030] An evaporation-boiling vertical coexistence composite structure for enhancing boiling heat transfer in this embodiment, such as figure 2 As shown, it includes a horizontally arranged heating substrate 1, the upper surface of the heating substrate 1 is fixedly installed with a porous capillary core 3 through a vertically arranged thermally conductive micro-column 2, and the lower surface of the porous capillary core 3 is provided with a protrusion 31. There is a superheated fluid working medium region 4 between 1 and the porous capillary core 3. The upper surface of the thermally conductive micropillars 2 and the lower surface of the porous capillary core 3 are connected by a sintering method to form a composite structure, and channels are formed between the composite structures.

[0031] In the composite structure of the present invention, the thermally conductive micropillars 2 are selected from materials with high thermal conductivity, such as copper, aluminum or gold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com