Installation method for inner support of lock catch steel pipe or steel sheet pile cofferdam

A technology of steel sheet pile cofferdam and installation method, which is applied to sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of difficult construction quality control, difficult control of locking steel pipe or steel sheet pile insertion precision, and high safety risk. Achieve the effect of shortening mechanical operation time, convenient and quick assembly, and less material input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

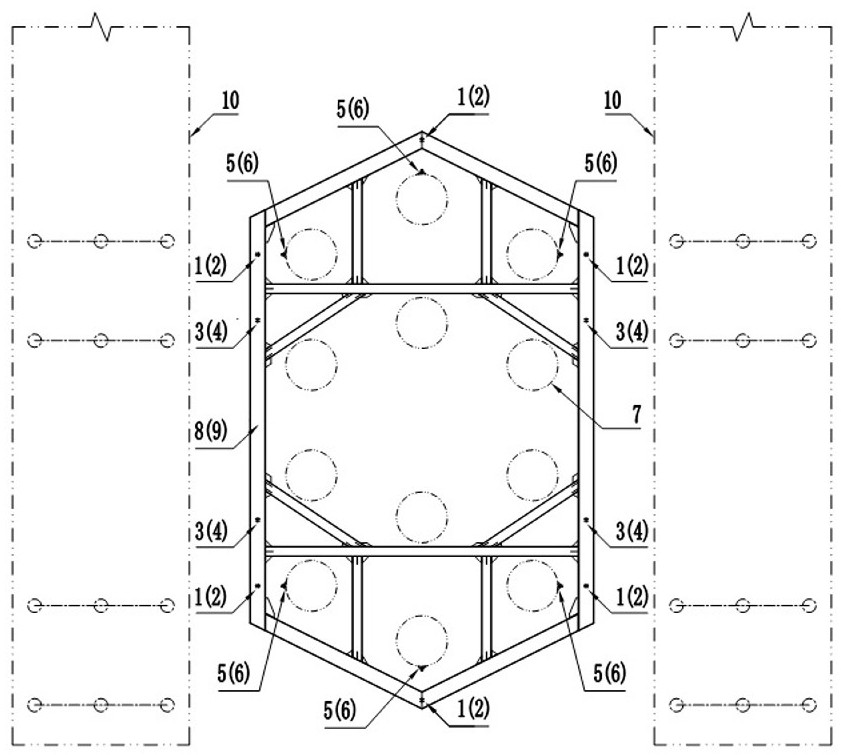

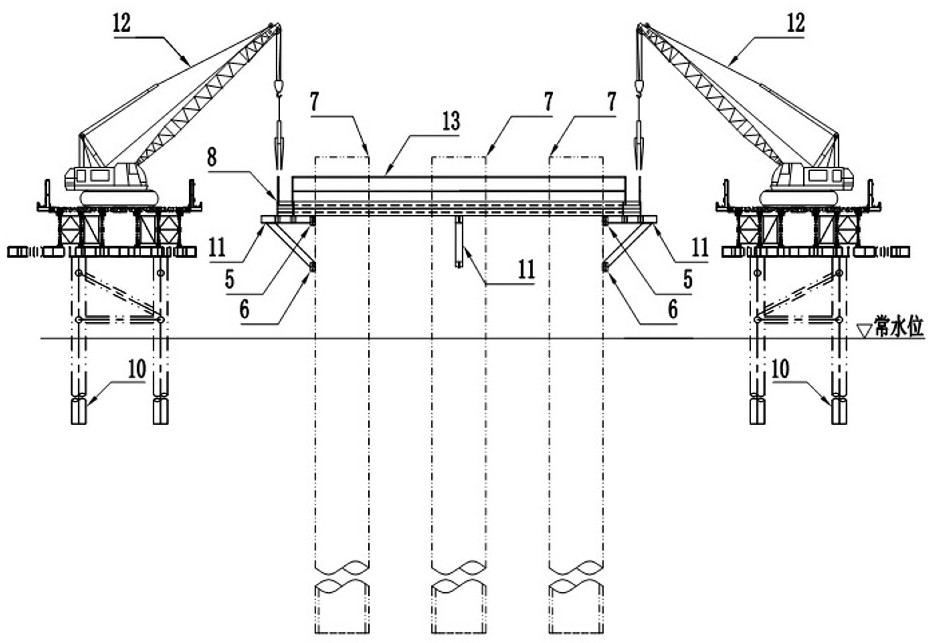

[0047] The present invention is further described in detail below in conjunction with examples of embodiments and against the accompanying drawings.

[0048] Embodiments of the present invention provides a method of mounting support within a locked steel pipe or steel sheet pile cofferdam, comprising the following steps:

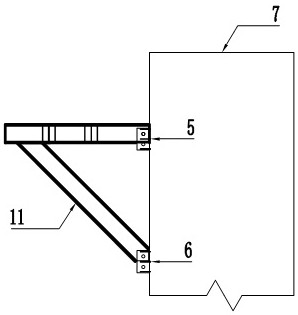

[0049] A. Before the implementation of the support construction in the locking steel pipe or steel sheet pile cofferdam, the drilling platform is dismantled, the trestle 10 on both sides is reserved as the operating platform, and the cutting steel guard cylinder is 7 to the unified elevation as the foundation of the bottom sealing platform;

[0050] B. Under the premise of ensuring hoisting and transportation, the lower inner support 8 and the upper inner support 9 are reasonably divided into several large sections, reducing the amount of on-site operation, and when processing in the factory, the matching processing between the sections is carried out, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com