Fly ash melting vitrification pretreatment system and method

A melting vitrification and pretreatment technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of many irregular sections, poor thermal strength, easy to be extracted, etc., and achieve environmental benefits and Significant economic benefits, improve molding rate and strength, solve the effect of wasting energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

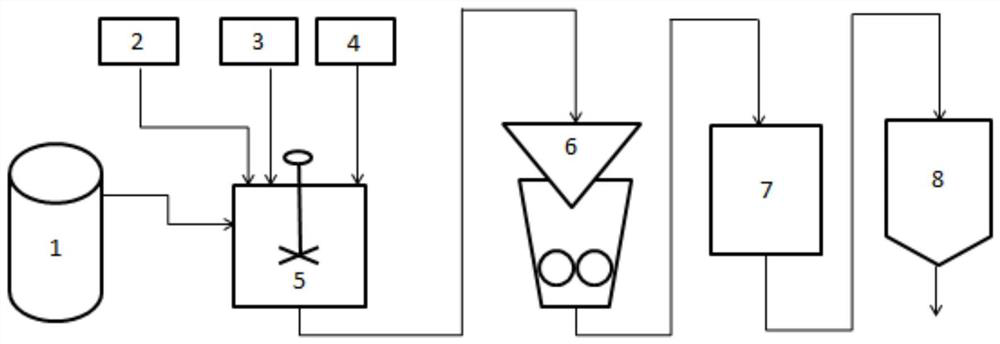

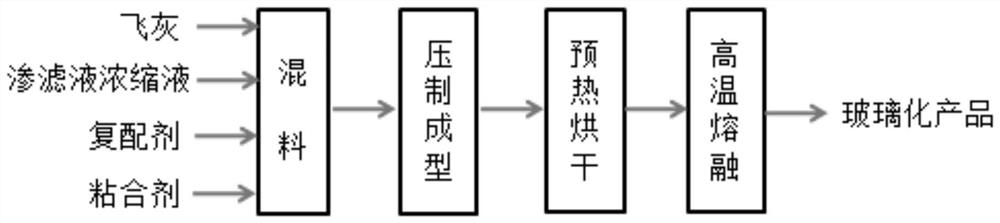

[0086] The present embodiment provides a method for pretreatment of fly ash melting and vitrification, using the pretreatment system of the present invention, comprising the following steps:

[0087] Step 1, use the mixing unit 5 to mix and stir the domestic waste incineration fly ash, leachate concentrate, compounding agent, and binder into a mixture; wherein, the addition of the domestic waste incineration fly ash is 65wt%, The addition amount of the domestic garbage leachate concentrate is 20wt%, the addition amount of the compounding agent is 11wt%, and the addition amount of the binder is 4wt%;

[0088] Step 2, using the molding unit 6 to extrude the mixture obtained in step 1 into an ellipsoidal raw material under an extrusion pressure of 23 MPa;

[0089] In step 3, the ellipsoid-shaped raw material obtained in step 2 is dried at 120° C. by the drying unit 7, and the raw material for high temperature molten vitrification with a moisture content of 8 wt% is obtained after...

Embodiment 2

[0092] The present embodiment provides a fly ash fusion vitrification pretreatment method, using the pretreatment system of the present invention, comprising the following steps:

[0093] Step 1, use the mixing unit 5 to mix and stir the medical waste incineration fly ash, leachate concentrate, compounding agent, binder, etc. in a certain place in Anhui into a mixture; wherein, the addition of the medical waste incineration fly ash is 70wt% , the addition amount of the domestic garbage leachate concentrate is 20wt%, the addition amount of the compounding agent is 7wt%, and the addition amount of the binder is 3wt%;

[0094] Step 2, using the molding unit 6 to extrude the mixture obtained in step 1 into an ellipsoidal raw material under an extrusion pressure of 23 MPa; preferably, the molding unit 6 adopts a high-pressure molding machine;

[0095] In step 3, the ellipsoid-shaped raw material obtained in step 2 is dried by the drying unit 7 to become the raw material for high te...

Embodiment 3

[0098] The present embodiment provides a fly ash fusion vitrification pretreatment method, using the pretreatment system of the present invention, comprising the following steps:

[0099] Step 1, use the mixing unit 5 to mix and stir the hazardous waste incineration fly ash, leachate concentrate, compounding agent, binder, etc. in a certain place in Inner Mongolia into a mixture; wherein, the addition amount of the hazardous waste incineration fly ash is 75wt% , the addition amount of the domestic garbage leachate concentrate is 16wt%, the addition amount of the compounding agent is 5wt%, and the addition amount of the binder is 4wt%;

[0100] Step 2, using the molding unit 6 to extrude the mixture obtained in step 1 into an ellipsoidal raw material under an extrusion pressure of 20 MPa;

[0101] In step 3, drying unit 7 is used to dry the ellipsoid raw material obtained in step 2 at 125° C., and after drying, a raw material for high temperature molten vitrification with a moi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com