Variable-spiral unequal-pitch end mill with surface microtexture

A technology of micro-texture and end mills, which is applied in the field of tooth pitch end mills, can solve the problems affecting the surface quality of workpieces that affect the machining accuracy, reduce the service life of tools, and vibration of the milling system, so as to improve processing stability and reduce milling. Heat, the effect of enhancing processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

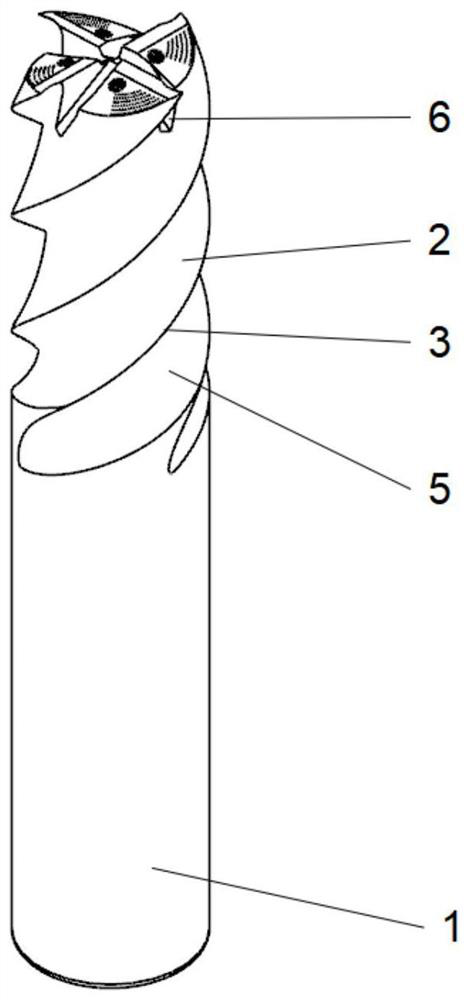

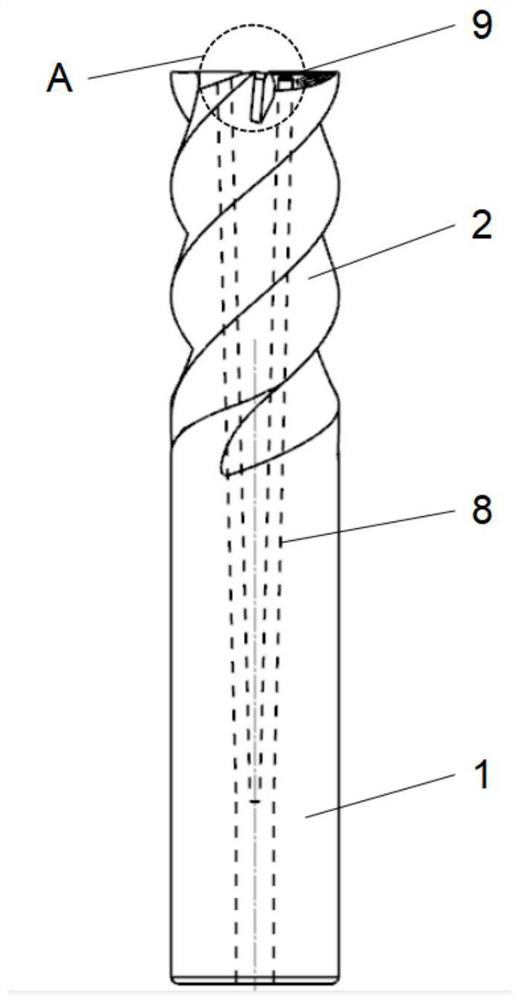

[0023] reference Figure 1-Figure 4 , a variable spiral unequal pitch end milling cutter with surface microwoven, including a shank (1) and a milling head (2), milling bit (2) with four perimeter milling edges (3) and four bottom milling edges (4), a spiral chip groove (5) and a crescent groove (6) between the perimeter cutter (3) and a bottom milling edge (4), a multi-row circular microwoven with a fan arrangement on the end face of the milling cutter (7), and multiple cooling channels (8) inside the milling cutter.

[0024] reference Figure 1 The circumferential milling edge (3) of the end mill adopts a variable spiral structure, and the square sum of the spectral amplitude deviation of the milling force is used as the target function for global optimization, and the optimization result is the β of the first tooth helix angle 1 and the third tooth helix angle β 3 40°, the second tooth helix angle β 2 and the fourth tooth helix angle β 4 It is 41° and has a spiral chip evacuation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com