Liquid metal functional composite film and preparation method thereof

A technology of liquid metal and composite thin film, which is applied in the direction of solar thermal power generation, etc., can solve problems such as inability to endow composite materials with photothermal conversion performance, achieve excellent photothermal performance and shielding performance, simple method, and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a liquid metal functional composite film, comprising the following steps:

[0029] (1) Weigh 5g of polyvinyl alcohol powder and 0.2g of sodium alginate as a surface modifier, add it to a beaker containing 100ml of deionized water, and heat it in an oil bath at 95°C for 2 hours to obtain an aqueous solution of polyvinyl alcohol-sodium alginate .

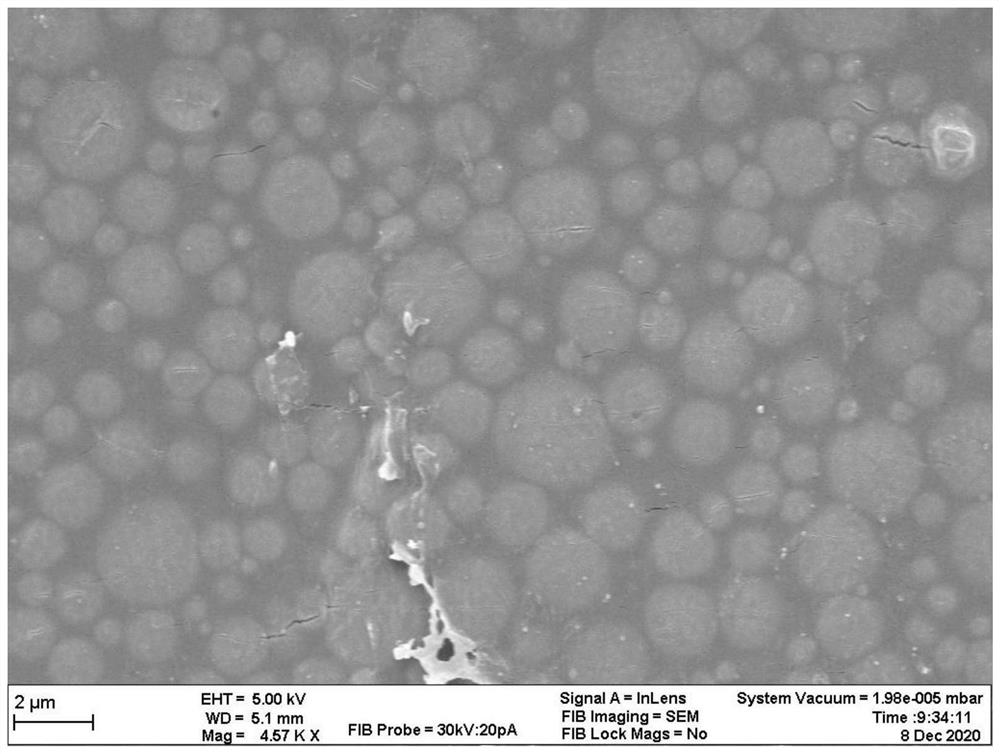

[0030] (2) Weigh 3 g of gallium-indium alloy, add the prepared polyvinyl alcohol-sodium alginate aqueous solution, and ultrasonicate for 5 minutes at 6 KHz to form liquid metal droplets wrapped by sodium alginate to obtain a liquid metal-polyvinyl alcohol solution.

[0031] (3) The liquid metal-polyvinyl alcohol solution was introduced into the prepared mold of 50mm×50mm×4mm, after flat casting, the solvent was evaporated at room temperature of 25°C for 24h, and the liquid metal functional film 1 was obtained after curing.

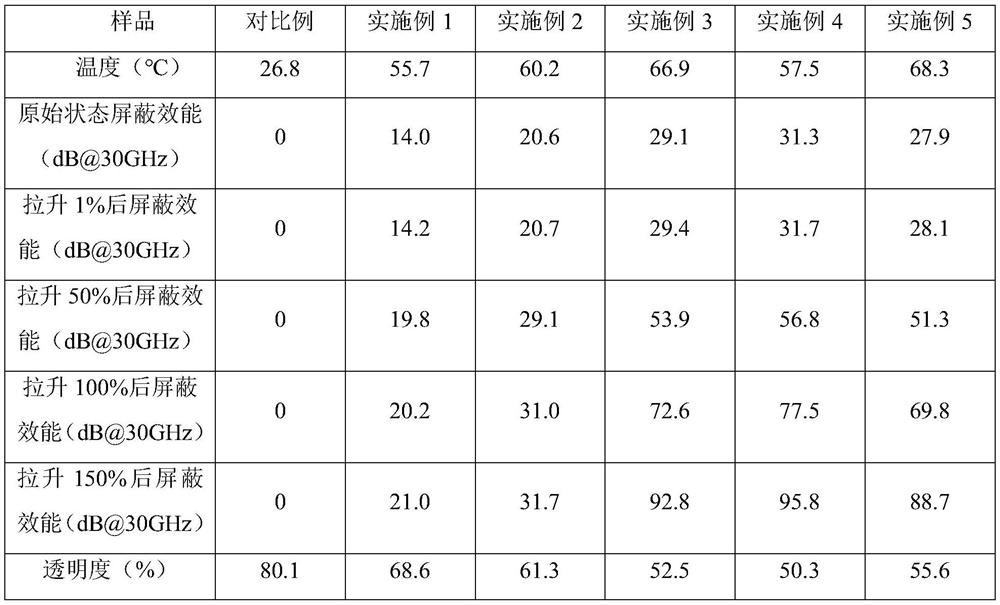

Embodiment 2

[0033] For the preparation method of the liquid metal functional film in this embodiment, refer to Example 1, the difference is only that in step (2) "weigh 4 g of gallium indium alloy" to obtain the liquid metal functional film 3 .

Embodiment 3

[0035] The preparation method of the liquid metal functional film in this embodiment refers to Example 1, and the difference is only that in step (2) "weigh 5 g of gallium indium alloy" to obtain the liquid metal functional film 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com