Zero-discharge sewage treatment process in nano-powder industry

A nano-powder and sewage treatment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, heating water/sewage treatment, etc., can solve the problems of water body secondary pollution, environmental pollution, immaturity, etc., to achieve The effect of zero sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

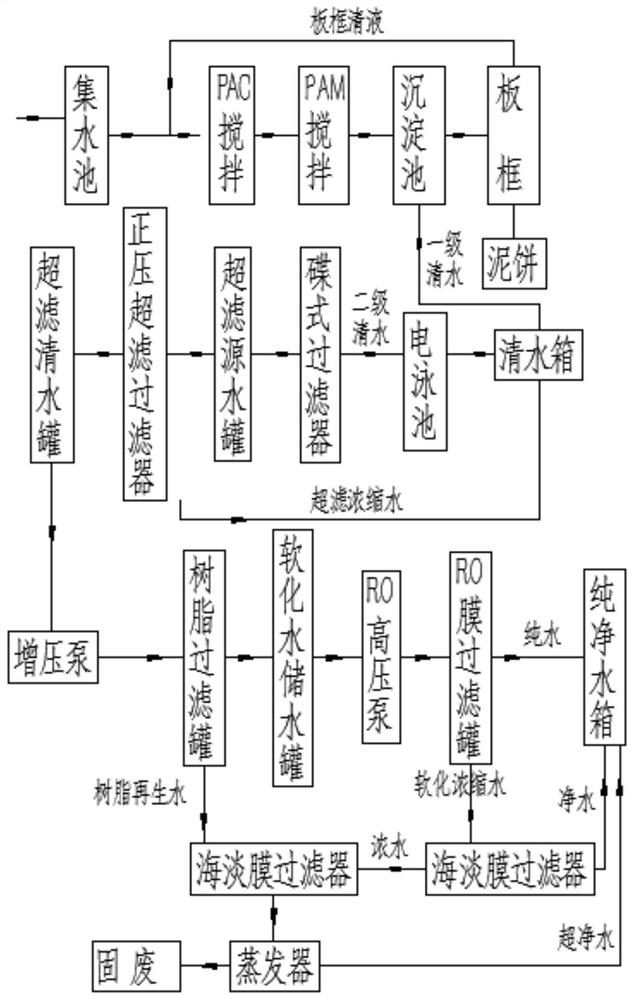

[0013] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will now be further described with reference to the accompanying drawings.

[0014] The technical scheme of the present invention is a zero-discharge sewage treatment process in the nano-powder industry, including a first-level flocculation tank, a second-level flocculation tank, a sedimentation tank, a battery pool, a disc filter, a positive pressure ultrafiltration filter, Resin filter tanks, RO membrane filter tanks, desalination membrane filters and evaporators. PAC and PAM flocculants are respectively added in the first-level flocculation tank and the second-level flocculation tank to flocculate and settle the nano-powder in the sewage; First class clean water. The first-grade clean water enters the disc filter for filtration to obtain ultrafiltration source water; the ultrafiltration source water is filtere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com