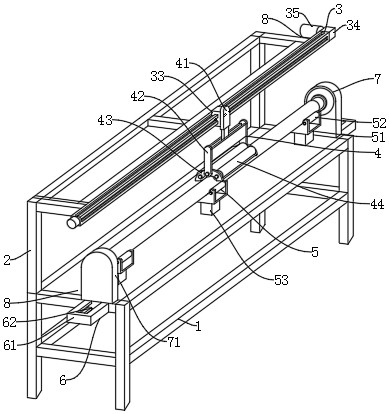

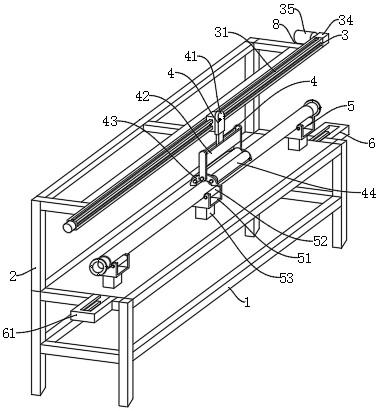

Back pipe indium preparation device

A technology of back tube and accessories, applied in the field of back tube indium preparation device, can solve the problems of unable to ensure uniform and stable rotation of back tube, restricted size of clamping, poor application compatibility, etc., so as to improve stability and performance, Convenient and quick stop and take off, easy to apply effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

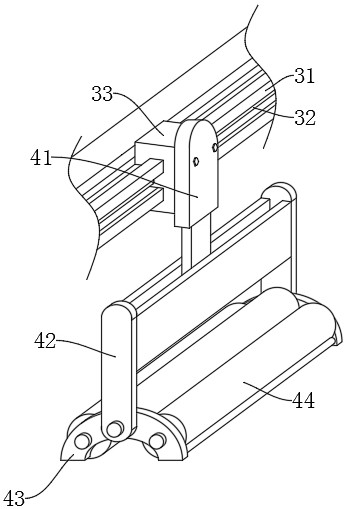

Examples

Embodiment approach

[0081] The specific embodiment is as follows: the external power supply of the device is turned on, and the stepping motor 35 is pulled into the square mouth of the second casing 86 by the lifting device and the rigging through the external control device control device, and then the stepping motor 35 is removed. Therefore, the motor has a downward effect on the second casing 86, and the cylindrical carrying bar 84 moves downward. Because the tooth bar 831 on the wall surface of the cylindrical carrying bar 84 is engaged with the worm gear 832 on the rotating roller 89, it is pulled in turn. The worm wheel 832 rotates, the rotating roller 89 rotates, and the rotating roller 89 pulls the translation piece 884 on its peripheral wall to move at the outer thread opening 891 of the rotating roller 89. Because the outer thread openings 891 at the two places are reversed, so a pair of The translation pieces 884 are facing each other, and the receiving bar 883 moves toward the first st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com