Preparation method of green and environment-friendly polyether polyurethane material

A polyether polyurethane, green and environmental protection technology, applied in the field of polyurethane, can solve the problems of reducing the flexibility of the molecular chain, high price, many solvents, etc., and achieve the effect of abundant stock and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

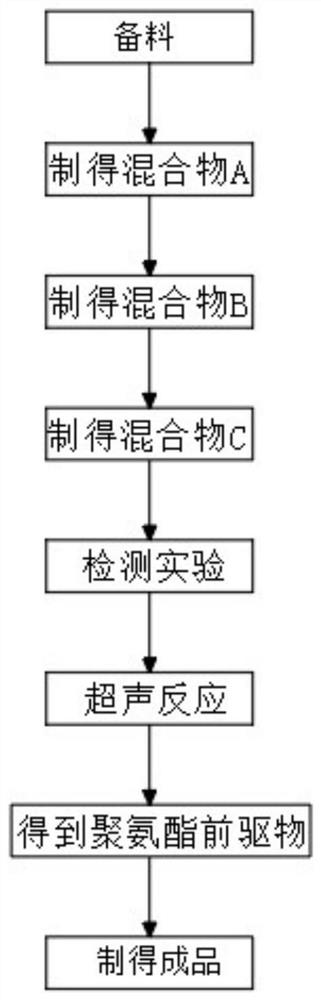

[0036] Such as figure 1 As shown, the embodiment of the present invention provides a kind of manufacturing method of the polyether type polyurethane material of environment-friendly type, comprises the following steps:

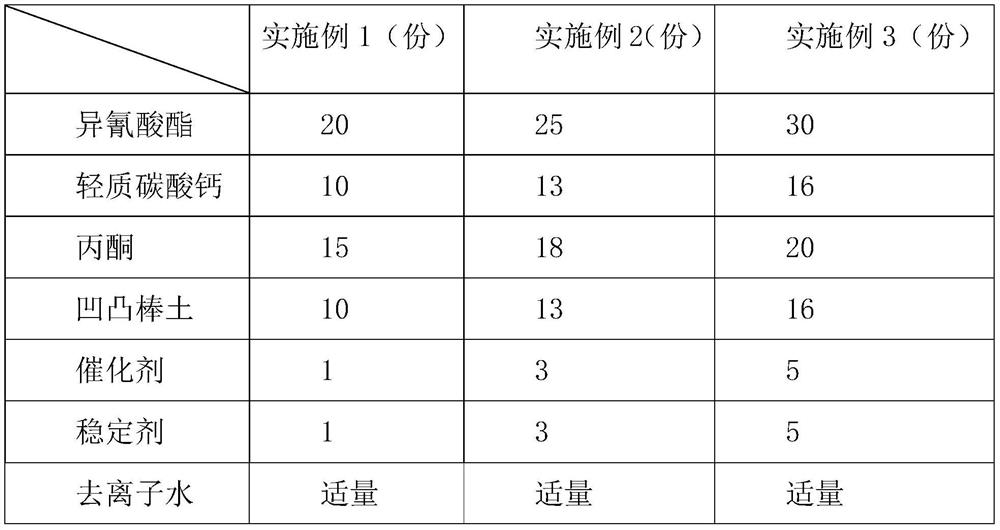

[0037] Treat the raw materials of polyether polyurethane materials, and weigh 20 parts of isocyanate, 10 parts of light calcium carbonate, 15 parts of acetone, 10 parts of attapulgite, 1 part of catalyst, 1 part of stabilizer, deionized water Appropriate amount, reserve;

[0038] The processing step of described light calcium carbonate is as follows:

[0039] Preliminary screening of coarse light calcium carbonate to remove impurities and larger particles;

[0040] Grinding the light calcium carbonate after screening;

[0041] The ground light calcium carbonate is sieved to obtain a particle size of 400-500 mesh.

[0042] The processing step of described attapulgite is as follows:

[0043] mixing attapulgite with deionized water equivalent to 8-10 times t...

Embodiment 2

[0057] Such as figure 1 As shown, the embodiment of the present invention provides a kind of manufacturing method of the polyether type polyurethane material of environment-friendly type, comprises the following steps:

[0058] Treat the raw materials of polyether polyurethane materials, and weigh 25 parts of isocyanate, 13 parts of light calcium carbonate, 18 parts of acetone, 13 parts of attapulgite, 3 parts of catalyst, 3 parts of stabilizer, deionized water Appropriate amount, reserve;

[0059] The processing step of described light calcium carbonate is as follows:

[0060] Preliminary screening of coarse light calcium carbonate to remove impurities and larger particles;

[0061] Grinding the light calcium carbonate after screening;

[0062] The ground light calcium carbonate is sieved to obtain a particle size of 400-500 mesh.

[0063] The processing step of described attapulgite is as follows:

[0064] mixing attapulgite with deionized water equivalent to 8-10 times...

Embodiment 3

[0078] Such as figure 1 As shown, the embodiment of the present invention provides a kind of manufacturing method of the polyether type polyurethane material of environment-friendly type, comprises the following steps:

[0079] Process the raw materials of polyether polyurethane materials, and weigh 30 parts of isocyanate, 16 parts of light calcium carbonate, 20 parts of acetone, 16 parts of attapulgite, 5 parts of catalyst, 5 parts of stabilizer, deionized water Appropriate amount, reserve;

[0080] The processing step of described light calcium carbonate is as follows:

[0081] Preliminary screening of coarse light calcium carbonate to remove impurities and larger particles;

[0082] Grinding the light calcium carbonate after screening;

[0083] The ground light calcium carbonate is sieved to obtain a particle size of 400-500 mesh.

[0084] The processing step of described attapulgite is as follows:

[0085] mixing attapulgite with deionized water equivalent to 8-10 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com