Amide-containing polysubstituted aromatic diamine monomer and preparation method thereof

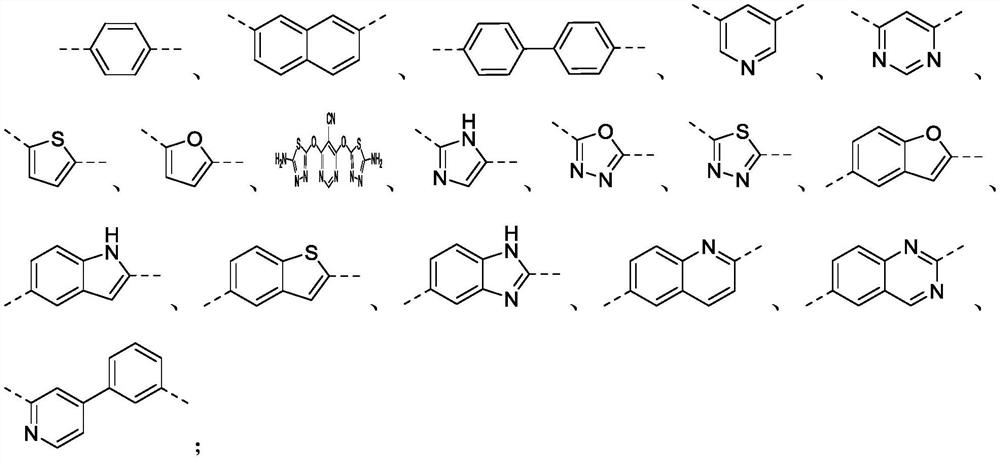

An aromatic diamine and multi-substitution technology, which is applied in the field of diamine monomer preparation, can solve the problems of inorganic alkali mechanical equipment corrosion, release huge heat, environmental pollution, etc., and achieve the effects of good solubility, low energy consumption and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] (1) Under the protection of nitrogen, add the substituent R with a molar ratio of 3.0:1.0 into a three-necked flask equipped with mechanical stirring. 1 The p-aminophenol A and m-dihalobenzamide compound B were further added with an appropriate amount of organic solvent and basic catalyst, stirred at room temperature for half an hour, then heated to 100°C for 10 hours, and then the reaction was terminated.

[0076] (2) White aromatic diamine monomer can be obtained after precipitation, filtration, drying and recrystallization.

[0077] Among them, the organic solvent selected in this embodiment is a mixture of 1,4-dioxane and N,N-dimethylformamide in a mass ratio of 4:6, and its dosage is the same as that of the para-amino The mass ratio of the amount of phenol and the m-dihalobenzamide compound is 3.0:1.0; the basic catalyst is potassium carbonate, and the mass ratio of its amount to the amount of p-aminophenol is 2.0:1.0; The alcohol that adopts during recrystallizat...

Embodiment 2-9

[0081] The specific implementation method is consistent with Example 1, except that the reaction temperature, reaction time and molar ratio of raw materials will be somewhat different. The specific setting parameters and the purity of the target product are shown in Table 1.

Embodiment 10

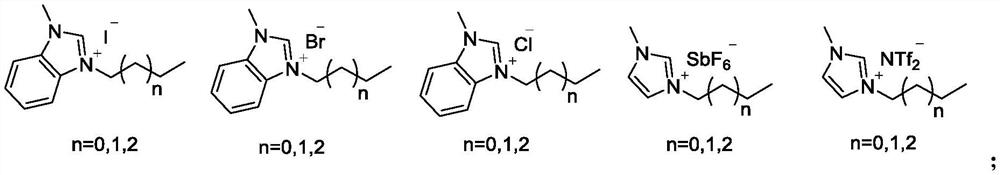

[0083] (1) Under the protection of ammonia gas, in a three-necked flask equipped with mechanical stirring, add a molar ratio of 2.0:1.0 with substituent R 1 The p-aminophenol A and m-dihalobenzamide compound B were further added with ionic liquid catalysts respectively, stirred at room temperature for half an hour, then heated to 60°C for 7 hours, and then the reaction was terminated.

[0084] (2) The product obtained by the reaction is centrifuged, and the solid obtained by the centrifugation is washed, dried and recrystallized to obtain a white aromatic diamine monomer.

[0085] Wherein, the rotating speed of centrifugal is 5000rpm, and the time of centrifugal is 30min, and the ion catalyst selected is ion catalyst 1, and the structural formula of described ion catalyst 1 is The mass ratio of its amount to the amount of the p-aminophenol and the m-dihalobenzamide compound is 2.0:1.0; the alcohol used for recrystallization is methanol; Ar1 Choose as: Ar 2 choose as The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com