Method for producing coaxial cable having thin-walled, radially closed outer conductor

A technology for coaxial cables and outer conductors, which is used in the manufacture of coaxial cables, insulating conductors/cables, and forming corrugations on conductors/cables, and can solve problems such as reducing wall thickness and drawing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

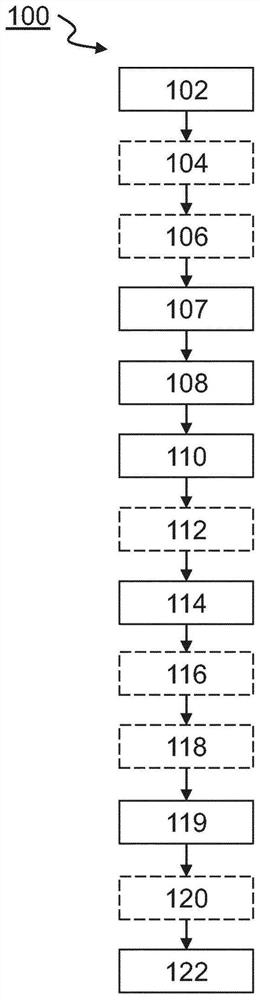

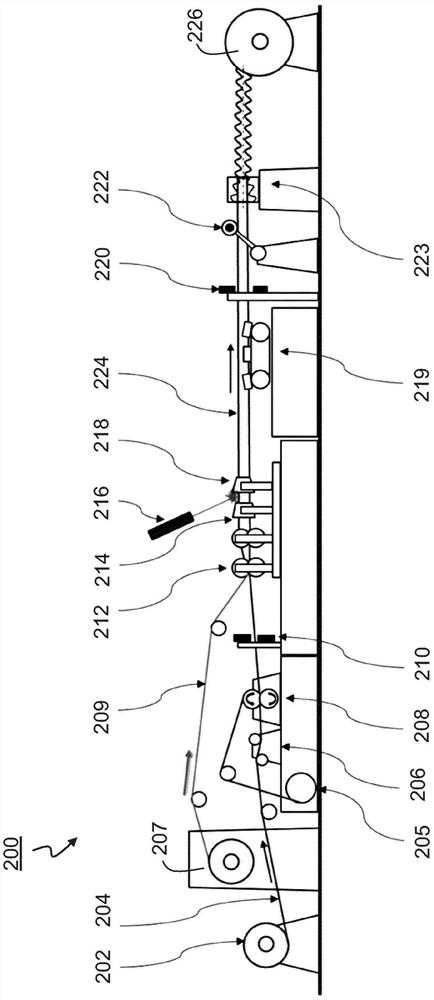

[0045] figure 1 The steps of a method 100 for producing a coaxial cable with a thin-walled, radially closed outer conductor are shown in accordance with one aspect of the present invention. In step 102 of the method, a flat strip made of a non-ferrous metal is supplied to a forming apparatus at a first supply speed. For example, flat copper strip is unwound from a reel. In the forming device, in step 108, the supplied flat strip is shaped into the form corresponding to the desired hollow profile of the outer conductor. For example, shaping can be achieved by means of roll forming tools.

[0046] During shaping, before the hollow profile forming the outer conductor is completely closed, the cable core is supplied comprising the inner conductor sheathed by dielectric and further layers, if appropriate. For example, a cable core has already been supplied in step 107 immediately before the first forming stage.

[0047] Before shaping, an optional step 104 may be performed in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com