Liquid crystal polymer composition and preparation method thereof

A technology of liquid crystal polymers and compositions, applied in the field of materials, can solve problems such as large lifting range and high dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 Liquid crystal polymer resin 1

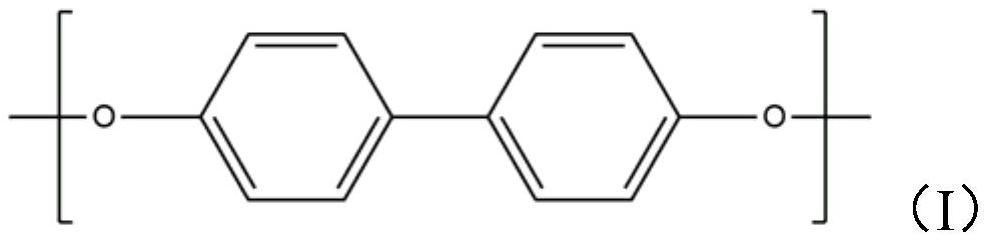

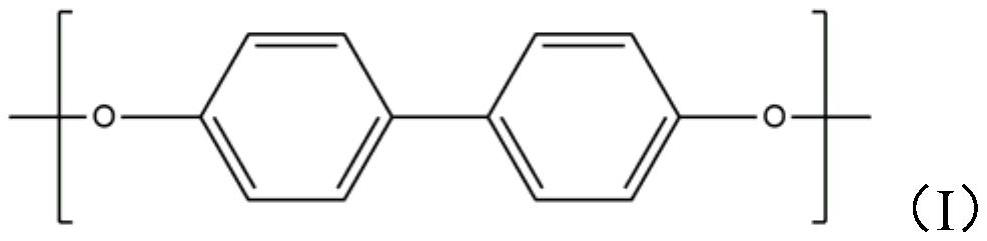

[0035] A liquid crystal polymer resin, comprising a structural unit shown in formula (I),

[0036]

[0037] In the liquid crystal polymer resin, the structural unit represented by formula (I) accounts for 20% by mole of all structural units.

[0038] The preparation method of the present embodiment liquid crystal polymer resin is as follows:

[0039]In a 100 liter reactor equipped with a nitrogen inlet and a stirrer with a stirring power display, add 61.2395 kg of p-hydroxybenzoic acid (HBA), 27.5200 kg of biphenol (BP), and 18.4146 kg of terephthalic acid (TPA) , 6.1382 kg isophthalic acid (IA) and 76.1938 kg acetic anhydride (AA) and 15.06 g magnesium acetate. After replacing the nitrogen, raise the reaction temperature to 145°C under a nitrogen atmosphere and reflux for 3 hours; then raise the temperature to 360°C at a rate of 60°C / hour, keep the reaction at this temperature for 30 minutes, and then evacuate to withi...

Embodiment 2

[0041] Embodiment 2 liquid crystal polymer resin 2

[0042] A liquid crystal polymer resin, comprising a structural unit shown in formula (I),

[0043]

[0044] In the liquid crystal polymer resin, the structural unit represented by formula (I) accounts for 25% by mole of all structural units.

[0045] The preparation method of the present embodiment liquid crystal polymer resin is as follows:

[0046] In a 100-liter reactor equipped with a nitrogen inlet and a stirrer with a stirring power display, add 1.6869 kg of p-hydroxybenzoic acid (HBA), 60.9038 kg of 2-hydroxy-6-naphthoic acid (HNA), 25.5844 kg of biphenyl diphenyl Phenol (BP), 22.8259 kg terephthalic acid (TPA) and 62.9641 kg acetic anhydride (AA) and 15.06 g magnesium acetate. After replacing the nitrogen, raise the reaction temperature to 145°C under a nitrogen atmosphere and reflux for 3 hours; then raise the temperature to 358°C (the highest pre-polymerization reaction temperature) at a rate of 60°C / hour, and...

Embodiment 3

[0048] Embodiment 3 liquid crystal polymer resin 3

[0049] A liquid crystal polymer resin, comprising a structural unit shown in formula (I),

[0050]

[0051] In the liquid crystal polymer resin, the structural unit represented by formula (I) accounts for 11.2% by mole of all structural units.

[0052] The preparation method of the present embodiment liquid crystal polymer resin is as follows:

[0053] In a 100-liter reactor equipped with a nitrogen inlet and a stirrer with a stirring power display, add 65.9614 kg of p-hydroxybenzoic acid (HBA), 7.1779 kg of 2-hydroxy-6-naphthoic acid (HNA), 15.9100 kg of biphenyl diphenyl Phenol (BP), 20.5315 kg terephthalic acid (TPA), 5.7658 kg para-acetaminophen (APAP) and 75.8369 kg acetic anhydride (AA) and 15.06 g magnesium acetate. After replacing the nitrogen, raise the reaction temperature to 145°C under a nitrogen atmosphere and reflux for 3 hours; then raise the temperature to 350°C at a rate of 60°C / hour, keep the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com