Nitrogen-phosphorus co-doped carbon fiber loaded CoP composite material, preparation method and application thereof, and aluminum air battery

A composite material and co-doping technology, which is applied in the field of aluminum-air batteries, can solve the problem of unsatisfactory conductivity of transition metal phosphide catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

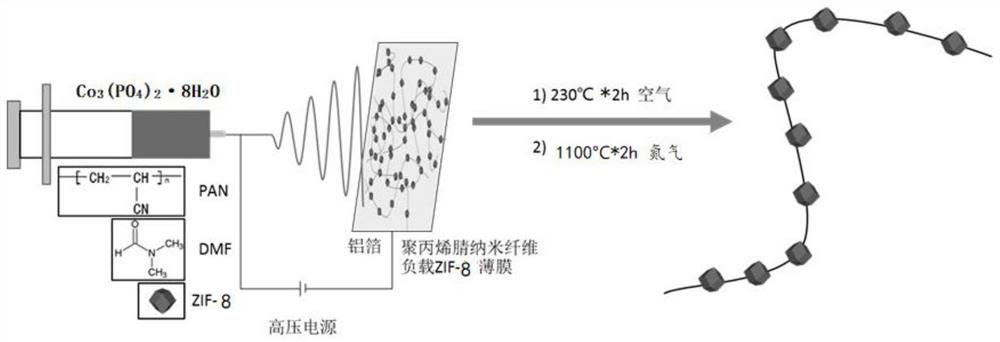

[0028] The present invention also provides a method for preparing a nitrogen-phosphorous co-doped carbon fiber-loaded CoP composite material described in the above technical solution, comprising the following steps:

[0029] Provide ZIF-8 organic solution and polyacrylonitrile organic solution;

[0030] mixing ZIF-8 organic solution, cobalt phosphate and polyacrylonitrile organic solution to obtain spinning precursor;

[0031] Electrospinning the spinning precursor solution to obtain polyacrylonitrile nanofiber loaded ZIF-8 film;

[0032] The polyacrylonitrile nanofiber loaded ZIF-8 film is pre-oxidized to obtain a pre-oxidized product;

[0033] The preoxidized product was placed in N 2 Pyrolysis is carried out in a protective atmosphere to obtain the nitrogen-phosphorus co-doped carbon fiber-loaded CoP composite material.

[0034] In the present invention, unless otherwise specified, each component in the technical solution is a commercially available product well known to...

Embodiment 1

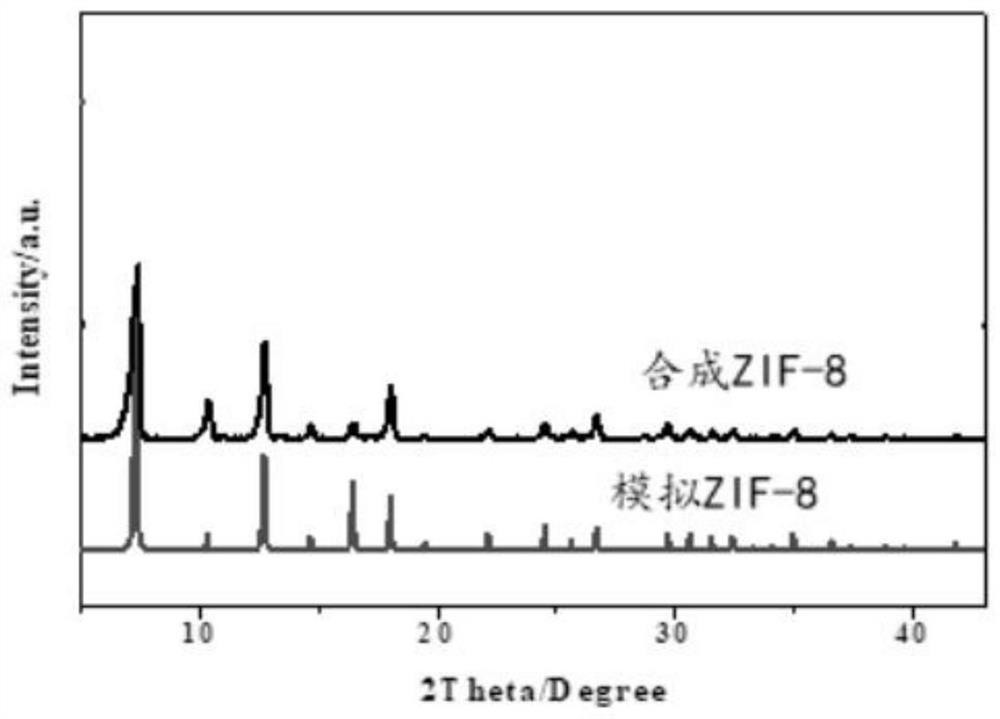

[0088] 2.5mmol of Zn(NO 3 ) 2 ·6H 2 Dissolve O in 50 mL of methanol, 20 mmol of 2-methylimidazole in 50 mL of methanol, then mix the two, stir at room temperature for 1 h, centrifuge to separate the precipitate, wash with methanol several times, and then heat to 60 ° C in a vacuum oven and dry overnight , to obtain ZIF-8 particles with a particle size of ≤1 μm;

[0089] The ZIF-8 particles prepared by 1.9g were washed with methanol and washed with DMF successively, then added 1mL of DMF and stirred evenly to obtain ZIF-8 organic solution; weighing 0.8g mass percentage concentration was 98% reagent pure cobalt phosphate (Co 3 (PO 4 ) 2 ·8H 2 O; 0.5g of PAN (M w =130000~150000) into 4mL of DMF, control the mass ratio of ZIF-8 particles, cobalt phosphate, and PAN to 1.9:0.8:1, and stir at 60°C for 6h, then mix and stir the above three solutions evenly to form spinning Precursor. Inhale the precursor liquid into the needle tube for electrospinning. The specific parameters ...

Embodiment 2

[0127] According to the method of embodiment 1, obtain the ZIF-8 particle of particle diameter≤1 μ m;

[0128] Wash 2.1g of prepared ZIF-8 particles with methanol and DMF successively, then add 1mL of DMF and stir evenly to obtain ZIF-8 organic solution; weigh 1.2g mass percent concentration of 98% reagent pure cobalt phosphate; PAN(M w =130000~150000) into 4mL of DMF, control the mass ratio of ZIF-8 particles, cobalt phosphate, and PAN to 1.1:1.2:1.3, and stir at 60°C for 6h, then mix and stir the above three solutions evenly to form spinning Precursor. Inhale the precursor solution into the needle tube for electrospinning. The specific parameters of the electrospinning are: the voltage is 20kV, the distance between the needle and the receiving plate is 20cm, the advancing speed is 20μL / min, the temperature is 30°C, and the humidity is 40%. Polyacrylonitrile nanofiber loaded ZIF-8 film;

[0129] After the electrospinning is completed, the polyacrylonitrile nanofiber-loaded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com