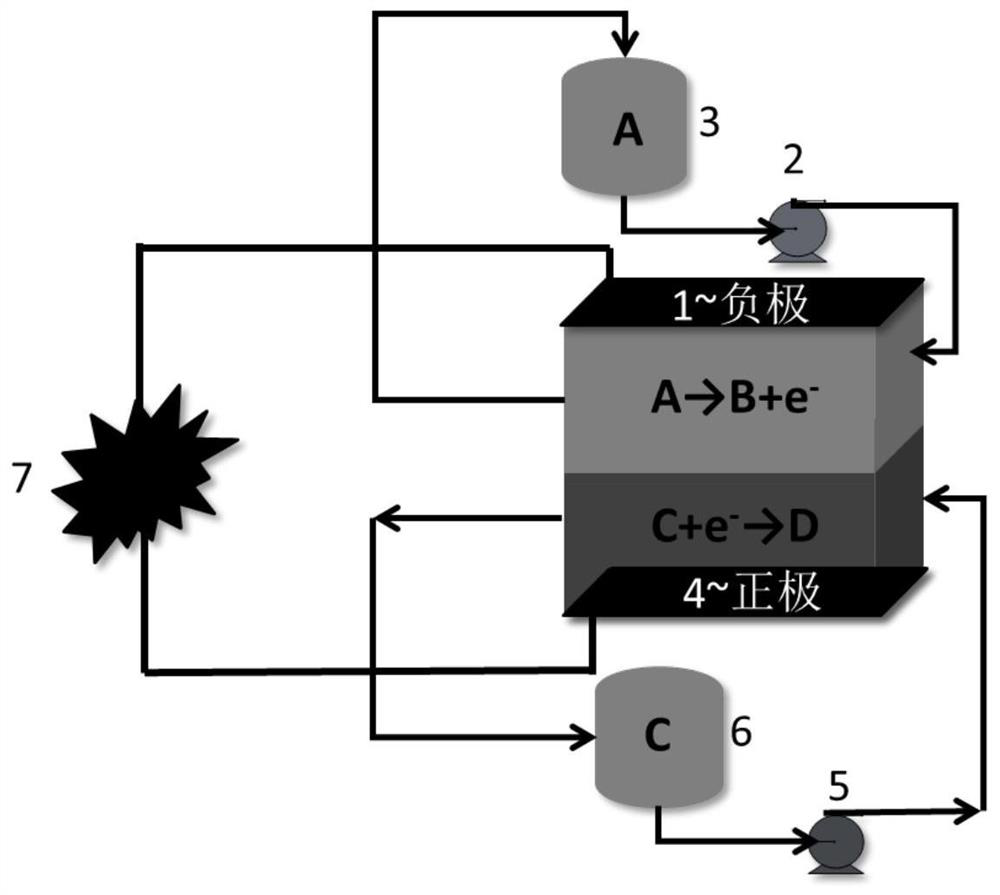

Positive electrode catalyst of flow battery and preparation method and application of positive electrode catalyst

A technology for flow batteries and catalysts, applied in battery electrodes, fuel cells, regenerative fuel cells, etc., can solve the problems of low selectivity and expensive cathode materials, and achieve high catalytic efficiency, low cost and high selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Positive electrode catalyst: prepare 0.25mol / L Mn(NO 3 ) 2 , 0.25mol / L Cu(NO 3 ) 2 With 1mol / L Co(NO 3 ) 2 0.05L of the mixed solution, add 4g co-precipitant ammonium sulfate (mass concentration is 5%) and 5g stabilizer polyvinyl alcohol (molecular weight is 18000), at a temperature of 180 ℃, time 8h, pH is 10 conditions to prepare the active group Divide the precursor suspension. The specific surface area of 17g is 300m 2 / g of carbon nanotubes at a temperature of 450 ° C, NH 3 , gas volume space velocity 5h -1 , contacted for 10h to prepare the modified carbon material. The modified carbon material was placed in the active component precursor suspension, treated with ultrasound at 60°C for 6h, then dried at 120°C for 4h under nitrogen atmosphere, and calcined at 400°C for 5h under nitrogen atmosphere to obtain the positive electrode of the flow battery catalyst.

[0057] Negative electrode catalyst: prepare 1mol / L H 4 PtCl 6 with 1mol / L FeCl 3 Equal vol...

Embodiment 2

[0061] Positive electrode catalyst: prepare 0.5mol / L Mn(NO 3 ) 2 , 0.25mol / L Cu(NO 3 ) 2 With 1mol / L Co(NO 3 ) 2 0.05L of the mixed solution, add 4g co-precipitant ammonium sulfate (mass concentration is 3%) and 5g stabilizer polyvinyl alcohol (molecular weight is 18000), at a temperature of 150 ℃, time 4h, pH is 8 conditions to prepare the active group Divide the precursor suspension. The specific surface area of 8g is 300m 2 / g of carbon nanotubes at a temperature of 450 ° C, through H 2 S, gas volume space velocity 5h -1 , contacted for 10h to prepare the modified carbon material. The modified carbon material was placed in the active component precursor suspension, treated with ultrasound at 60°C for 6h, then dried at 120°C for 4h under nitrogen atmosphere, and calcined at 400°C for 5h under nitrogen atmosphere to obtain the positive electrode of the flow battery catalyst.

[0062] Negative electrode catalyst: prepare 1mol / L H 4 PtCl 6 with 1mol / L FeCl 3 Equa...

Embodiment 3

[0066] Positive electrode catalyst: prepare 0.05mol / L Fe 2 (NO 3 ) 3 , 0.5mol / L Mn(NO 3 ) 2 , 0.15mol / L Cu(NO 3 ) 2 With 1mol / L Co(NO 3 ) 2 0.05L of the mixed solution, add 5g co-precipitant ammonium sulfate (mass concentration is 10%) and 5g stabilizer hexadecyltrimethylammonium bromide, at a temperature of 180 ° C, time 12h, pH 12 conditions Active component precursor suspension; 10g specific surface area 300m 2 / g of carbon nanotubes at a temperature of 450 ° C, through H 2 S, gas volume space velocity 5h -1 , and contacted for 10 hours to obtain the modified carbon material; the modified carbon material was placed in the active component precursor suspension, treated with ultrasound at 60°C for 6h, then dried at 120°C for 4h, and calcined at 400°C under a nitrogen atmosphere 5h, the positive electrode catalyst of the liquid flow battery was prepared.

[0067] Negative electrode catalyst: prepare 1mol / L H 4 PtCl 6 with 1mol / L FeCl 3 Equal volume mixed solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com