Yolk-shell type carbon-coated silicon composite negative electrode material and preparation method thereof

A negative electrode material, carbon coating technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of low initial charge and discharge efficiency, electrode structure deterioration, capacity decline, etc., to achieve integrity and avoid hydrogen Bubble, reduce the effect of extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

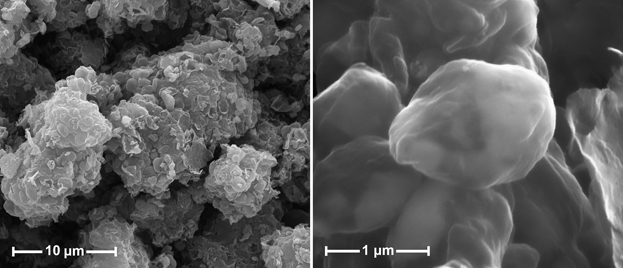

[0036] A method for preparing a yolk-shell carbon-coated silicon composite negative electrode material, comprising the following steps:

[0037] (1) 60 g of silicon-aluminum alloy powder (1 μm, 21wt.% Si) and ethanol solution (50 wt.%) containing 6 g of acrylonitrile-acrylic acid copolymer were mixed and ball-milled for 6 h, and 74 g of graphite powder (2000 mesh), ball milled for 12 h, dried in vacuum at 40°C to remove ethanol, and ball milled for 12 h after completely removing ethanol.

[0038] (2) Use a 300-mesh sieve to sieve out the composite particle fine powder, and heat-treat the composite powder in a tube furnace at 550 °C in a nitrogen atmosphere for 5 h.

[0039](3) Slowly add the heat-treated composite powder in step (2) into 3mol / L copper dichloride aqueous solution in batches and stir to disperse. As the blue copper dichloride is reduced to colorless cuprous chloride by aluminum, The color of the solution gradually becomes lighter (the reaction may produce brown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com