Aluminum alloy core photovoltaic cable convenient to disassemble and assemble

A technology of photovoltaic cables and aluminum alloys, which is applied in the dismantling/armouring of cable equipment, insulated cables, cable installation, etc., can solve problems such as corrosion and cracking, and achieve the effect of improving efficiency and increasing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

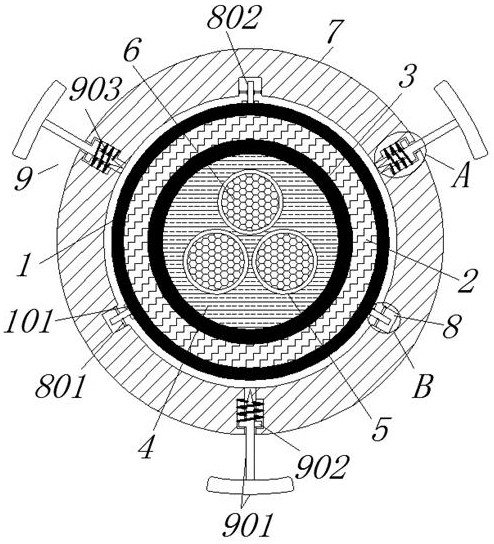

[0027] see figure 1 The sliding mechanism 8 includes a movable shaft 801 bearing connected to the inner side of the slider 7, and a pulley 802 is fixed on the outer side of the movable shaft 801. The cutting mechanism 9 includes a cutting bar 901 engaged in the inner side of the slider 7 through an inner groove, and the cutting bar 901 A movable block 902 is fixed on the outer side, a spring 903 is engaged on the outer side of the cutting strip 901, and a chute 101 is distributed on the outer side of the outer sheath 1, and the chute 101 and the pulley 802 form a front and rear sliding structure. Cutting strip 901, then forcefully cooperate with spring 903 and movable block 902 to press cutting strip 901, after pressing cutting strip 901 to the inner side of outer sheath 1, fire insulation layer 2, temperature insulation layer 3 and high temperature resistant filling 4, with this Simultaneously, push the cutting bar 901 on the chute 101 in cooperation with the movable shaft 80...

Embodiment 2

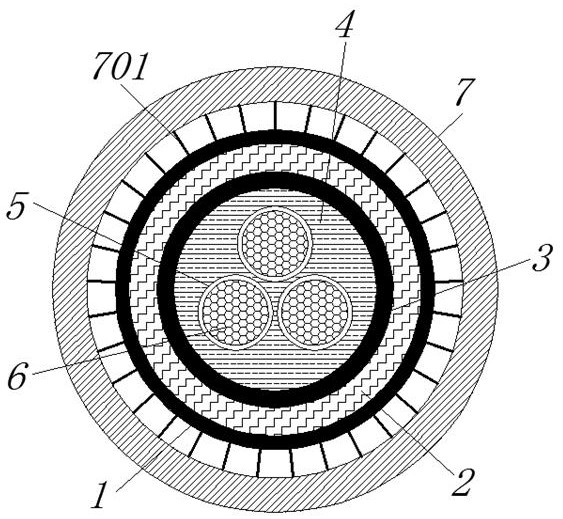

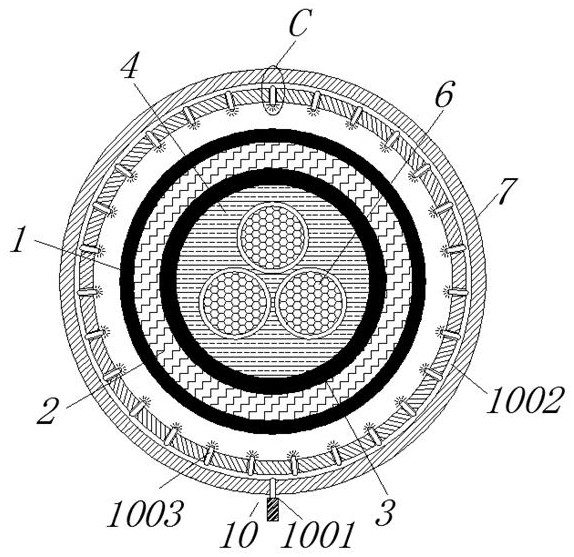

[0029] see Figure 1-6 The difference from Embodiment 1 is that the maintenance mechanism 10 includes a joint 1001 fixed below the slider 7, and an inner pipe 1002 is connected through the upper part of the joint 1001, and the inside of the inner pipe 1002 is welded with a nozzle 1003, and the outer side of the joint 1001 is threaded. shape, the inner pipe 1002 is in the shape of a ring, and a brush 701 is installed on the inside of the slider 7. Firstly, the paint inlet pipe connected by the micro paint pump is threaded and sealed with the joint 1001, and then the slider 7 is manually slid, so that the slider 7 The inner brush 701 can effectively brush the dust adhered to the outer surface of the aluminum alloy core photovoltaic cable, and at the same time start the micro paint pump connected to the outer side, so that the maintenance paint enters the inner tube 1002 and the The inner side of the nozzle 1003, and then evenly spray the outer sheath 1 of the aluminum alloy core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com