Water-activated sheet, water-activated label using said sheet, production method for said label, label adhering device using said label, and adherend for said label

A label sticking and water activation technology, applied in chemical instruments and methods, film/sheet adhesives, labels, etc., can solve the problems of sticking work, washing water pollution, label residue, etc., and achieves easy management. , the effect of reducing pollution and reducing residual glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0180] Hereinafter, an Example and a comparative example are given and the characteristics of this invention are demonstrated more concretely. Materials, usage-amounts, ratios, processing contents, processing procedures, and the like shown in the following examples can be appropriately changed as long as they do not deviate from the scope of the present invention. Therefore, the scope of the present invention should not be limitedly interpreted based on the specific examples shown below.

[0181] In the embodiment, the adherend with the label is manufactured according to the following steps: a paper material comprising a water-absorbing layer is manufactured, an adhesive layer is formed on the surface of the water-absorbing layer, and a water-activated sheet is obtained, which is then die-cut into required The size and shape can be used to make water-activated labels, and the labels can be pasted on the adherend using a water-activated label application device.

[0182] Furth...

manufacture example 1)

[0188] Using two extruders set at 250°C, the compound for the water-absorbing layer and the compound for the printable layer described in Table 2 were melt-kneaded separately, and the respective compounds were laminated in the die, and extruded. It is formed into a sheet and cooled to 70° C. by a cooling device to obtain an unstretched multilayer resin film.

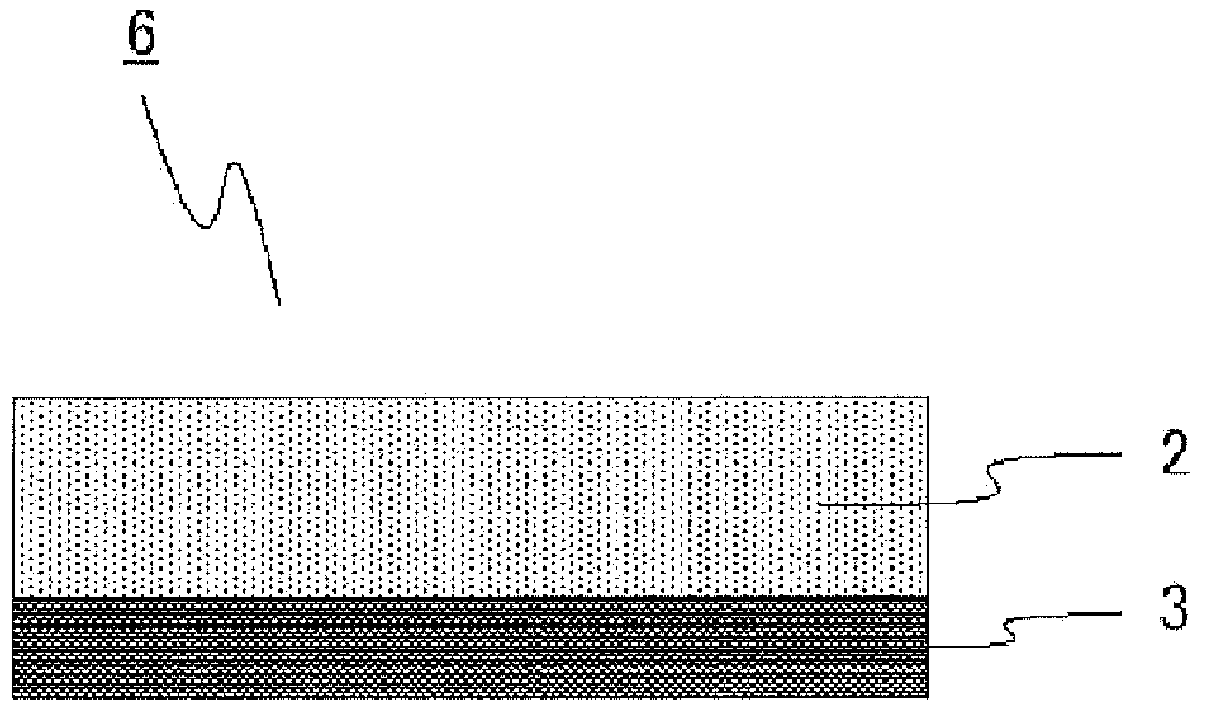

[0189] After heating the film, at the stretching temperature (1) described in Table 2, stretching was performed between rolls in the longitudinal direction at the stretch ratio described in Table 2. Thereafter, heat treatment was performed with a roll set at a temperature 20° C. higher than the stretching temperature (1), followed by cooling to obtain a multilayer resin stretched film. Next, both sides of the obtained multilayer resin stretched film were subjected to 40w / m 2 Minutes of corona treatment to obtain uniaxially stretched / uniaxially stretched paper with thicknesses shown in Table 2 (cf. figure 2 ).

manufacture example 2~4、7~10)

[0191] Melt and knead the compound of the printable layer described in Table 2 using an extruder set at 250°C, extrude it into a sheet, and cool it to 70°C with a cooling device to obtain an unstretched single-layer resin film. After the film was heated to the stretching temperature (1) described in Table 2, it was stretched between rolls in the longitudinal direction at the stretch ratio described in Table 2 to obtain a longitudinally uniaxially stretched film.

[0192] Next, using an extruder set at 250°C, the compound of the water-absorbing layer described in Table 2 was melt-kneaded, laminated on one side of the above-mentioned longitudinal uniaxially stretched film, and then heated to the stretching temperature described in Table 2. temperature (2), and then use a tenter to stretch in the transverse direction according to the stretching ratio recorded in Table 2, heat treatment at a temperature 20°C higher than the stretching temperature (2), and then cool to obtain a mul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com