Three-dimensional multi-particle finite element simulation method for predicting high-speed pressing forming performance of metal powder

A metal powder, high-speed pressing technology, applied in design optimization/simulation, instrument, image data processing, etc., can solve problems such as error-prone, labor-intensive, time-consuming, and cumbersome process, achieve completeness and correctness, reduce labor and time cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

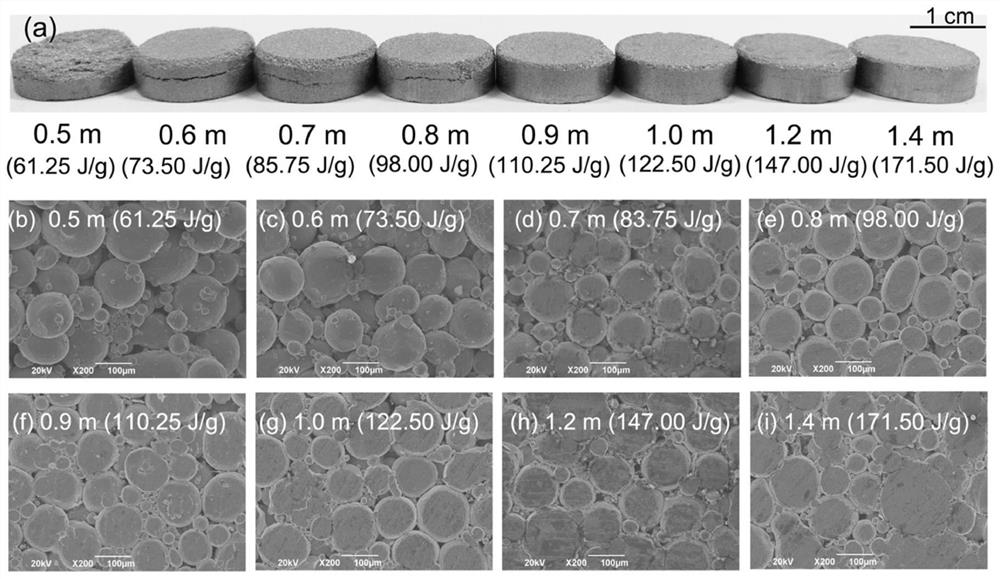

[0054] Embodiment 1 (Ti-6A1-4V powder compaction experiment)

[0055] The experiment is carried out on the high-speed pressing machine built. The experimental device is mainly composed of upper and lower punches, molds, and hammers. The whole high-speed pressing process consists of three steps of powder filling, compaction and discharge. Before powder filling, the die walls were lubricated with zinc stearate dissolved in acetone to facilitate ejection of the compact. The Ti-6Al-4V powder with a mass of 4.0 g was poured into the mold cavity and sandwiched between the upper and lower molds. During compaction, a weight is released at a specific height and then impacts the upper punch to compress the powder. Impact energy density per unit mass E′ in the experiment m defined as:

[0056]

[0057] Where: M=50Kg is the mass of the hammer body, H is the initial hanging height of the hammer, and m=4.0g is the mass of Ti-6A1-4V powder. A strain gauge was installed on the lower p...

Embodiment 2

[0059] Embodiment 2 (Ti-6Al-4V analog analysis experiment)

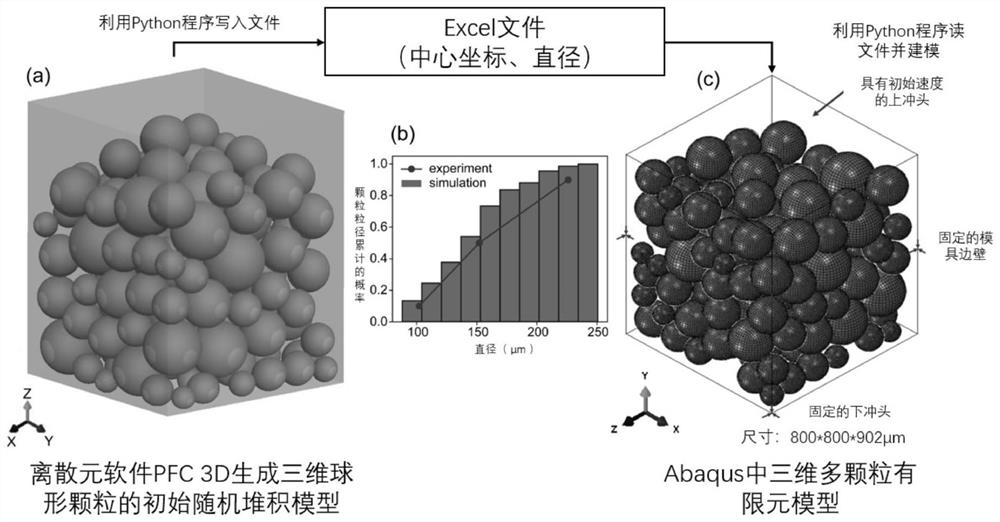

[0060] First, the discrete element software PFC 3D is used to generate the initial random packing model of three-dimensional spherical particles, such as figure 2 As shown, the diameter range of the three-dimensional spherical particles generated in it is 105-250 microns, and the distribution law is close to the Gaussian function, which matches the diameter distribution law of the powder used in the experiment: the container size is 800×800×902 mm, containing 142 spherical particles The porosity of the accumulation model is 0.175, which is consistent with the porosity of the powder used in the experiment; then the data of the center coordinates and diameter of each spherical particle are obtained, and the corresponding finite element model is generated by running the python script in the finite element software Abaqus.

[0061] Set the material properties, where the density of the Ti-6Al-4V material is 4.42g / cm 3 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com