Metallurgical gas electric heating device and heating system

An electric heating device and heating system technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., to reduce carbon consumption and ensure long-term safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

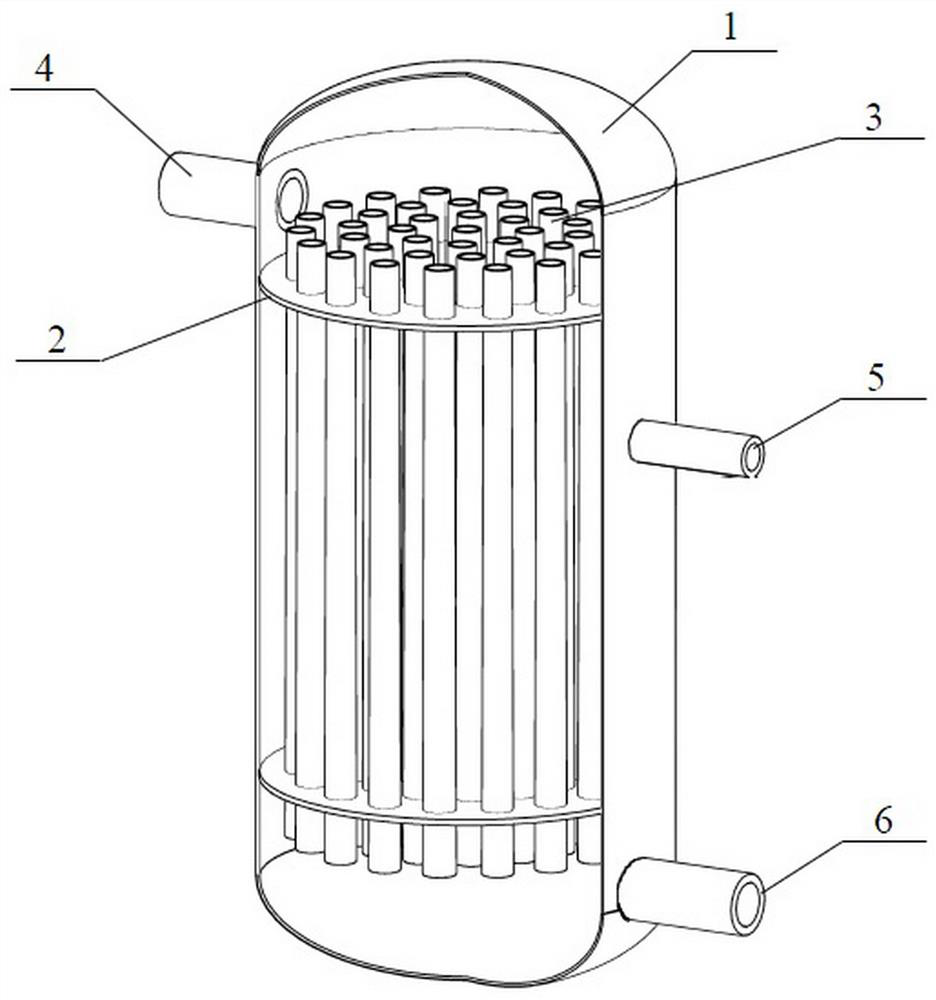

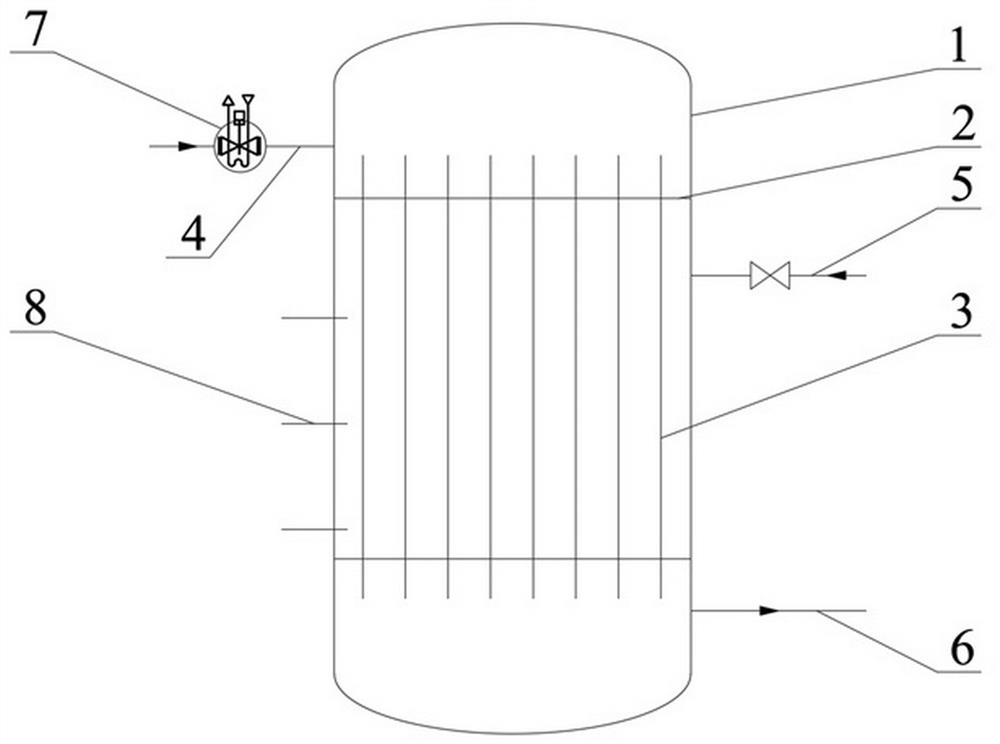

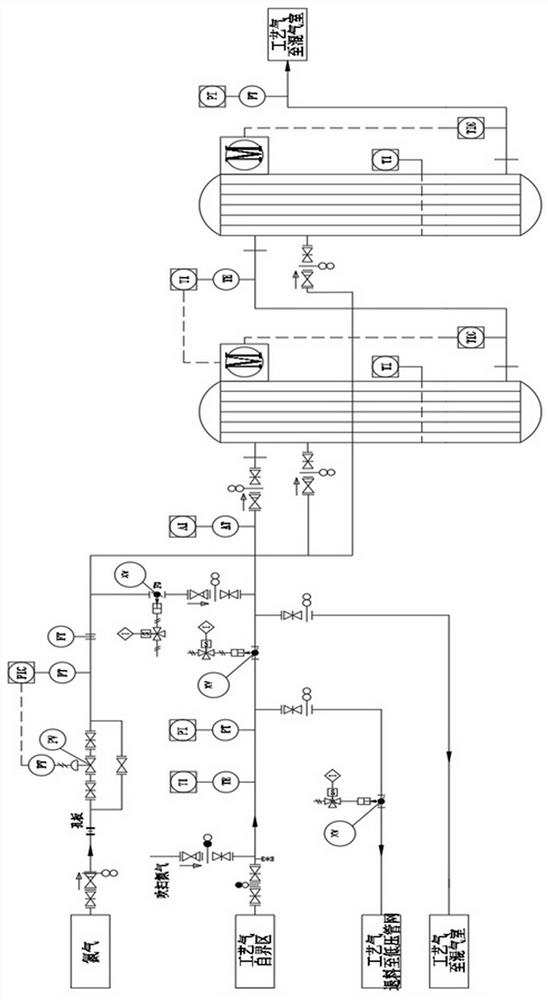

[0028] see Figure 1-2 , a metallurgical gas electric heating device, comprising a vertical tank body 1, the upper and lower ends of the tank body 1 are elliptical heads, the upper and lower ends of the tank body 1 are provided with baffles 2, and several resistors are arranged between the baffles 2 The two ends of the tube 3 and the resistance tube 3 pass through the baffles 2 at the upper and lower ends respectively, the upper end of the side of the tank body 1 is provided with a gas inlet pipe 4, the lower end is provided with a gas outlet pipe 6, and the side of the tank body 1 is provided between the upper and lower baffle plates 2 Nitrogen gas enters the pipe 5.

[0029] Further, the gas inlet pipe 4 is provided with a flow regulating valve 7 for adjusting the amount of gas entering the heater.

[0030] Further, electrodes and resistance tubes 3 are provided on the baffle plate 2, and the electrodes are used to energize the resistance tubes and heat the gas.

[0031] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com