Coal gas heating method for iron-making blast furnace

A technology for gas heating and iron-smelting blast furnaces, applied in air heaters, blast furnaces, blast furnace details, etc., and can solve problems such as fire, limited heating temperature, and explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

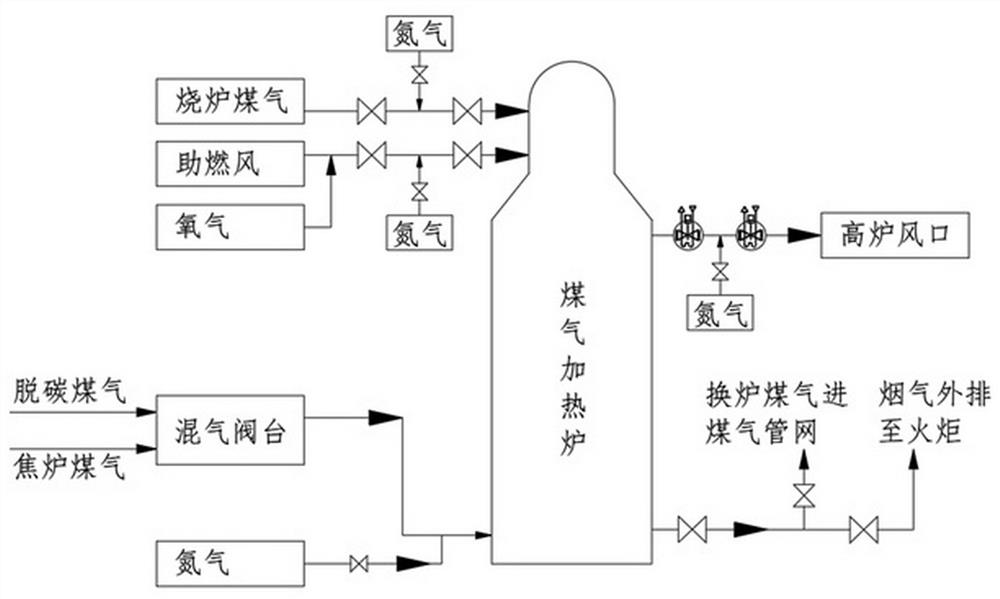

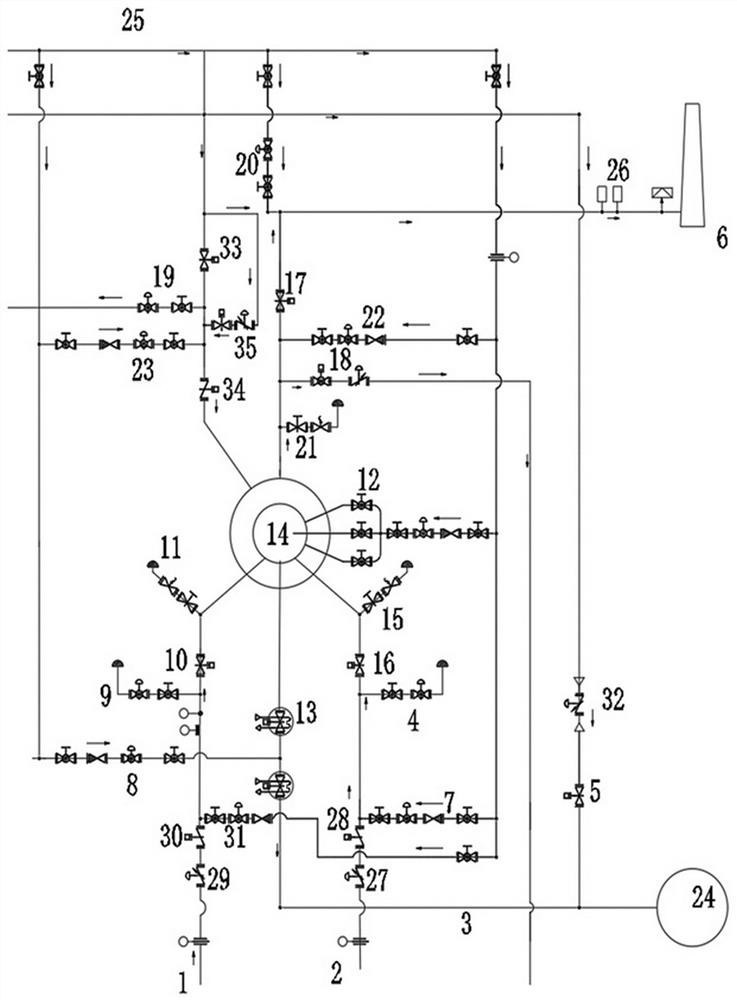

[0023] see Figure 1 to Figure 2 , a gas heating method for ironmaking blast furnaces,

[0024] A gas heating method for an ironmaking blast furnace. After the gas heating furnace is fired, an inert gas is introduced to drive the waste gas out of the flue to the mouth of the flue. 2 , CO is lower than 1%, the metallurgical normal temperature pressurized gas is introduced into the inlet of the gas heating furnace, and it is sent out from the outlet after heating. -1300°C mixed gas, and then inject the mixed gas into the blast furnace, when the temperature of the mixed gas is lower than 1200°C, replace other fired furnaces to feed gas to the gas heating furnace. Close the inlet valve and outlet valve of the gas heating furnace after the gas supply is completed, open the residual gas recovery valve in the furnace, discharge the residual high-pressure gas in the furnace to the low-pressure gas main pipe, and introduce inert gas after the pressure in the furnace drops to the press...

Embodiment

[0036] In September 2019, the 2500m³ blast furnace of Bayi Iron and Steel Co., Ltd. was repaired, and the three top-fired gas heating furnaces used in the blast furnace were simultaneously transformed, and the gas heating furnace low-pressure gas discharge channel, double hot air valve and nitrogen sealing mechanism were installed, and the safety control system was installed. Added CO, O 2 The on-line monitoring chain control system, after the intermediate repair, coke oven gas was blown into the gas heating furnace for the test, and the gas was successfully heated to 1100°C through the gas heating furnace and injected into the blast furnace.

[0037] In this process, first use the 1# gas heating furnace to supply air, first open its flue valve, and pass the furnace gas and combustion-supporting air into the 1# gas heating furnace, and the fed gas and air are in the combustion chamber of the 1# gas heating furnace Combustion, when the temperature of the vault of the 1# gas hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com