Graphene modified rubber composite material for tire tread and mixing method thereof

A technology of graphene modification and composite materials, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as poor wear resistance, increase mechanical properties, increase strength and hardness, reduce wear loss and The effect of puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

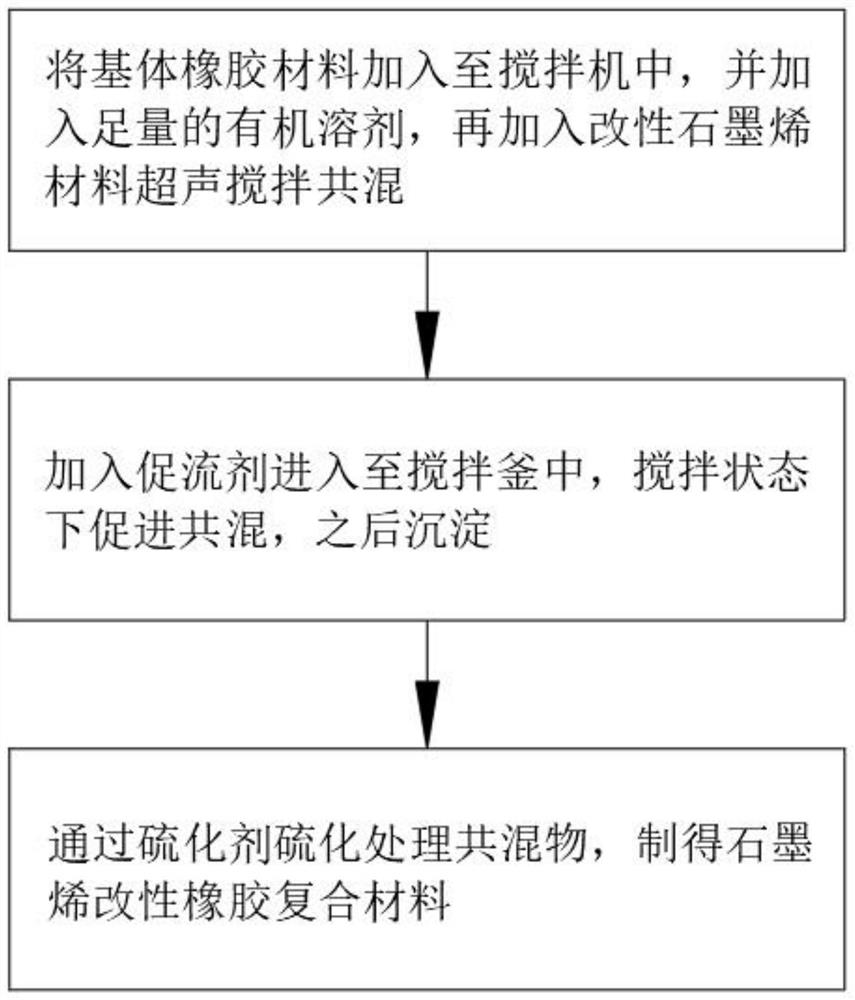

Method used

Image

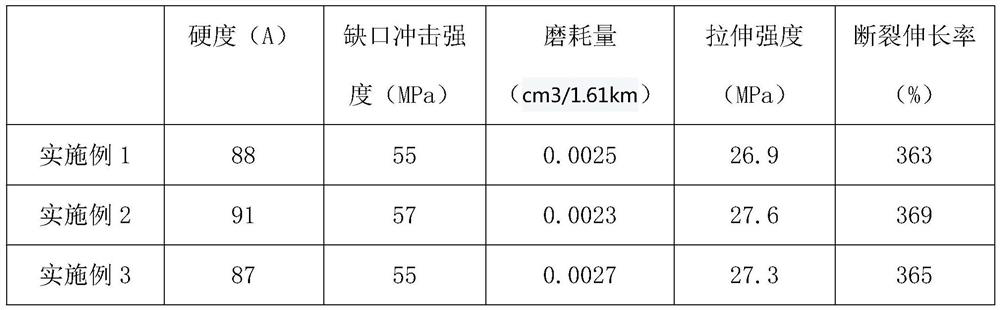

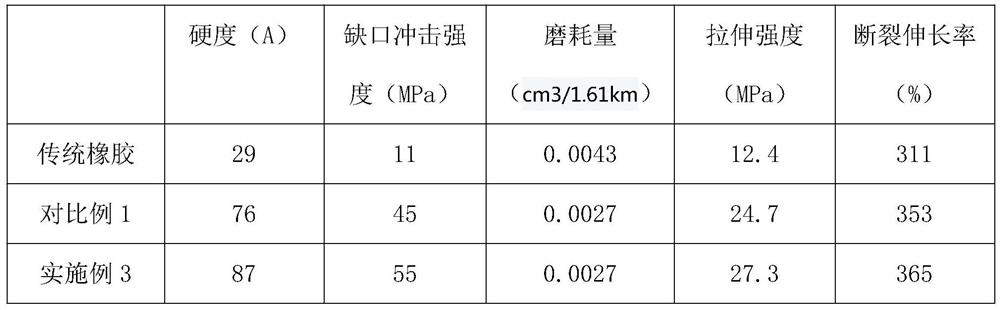

Examples

Embodiment 1

[0026] Embodiment 1 A kind of graphene modified rubber composite material and mixing method thereof for tire tread, comprising:

[0027] 1. Preparation of modified graphene materials

[0028] 1. Add 20 parts of graphene powder and N,N-dimethylamide solution into the stirring tank, stir at room temperature, raise the temperature to 60°C, add water to stir and dilute, and form A liquid;

[0029] 2. Preheat the stirred tank to 80°C, then add 15 parts of polyvinyl chloride powder and keep stirring at 80°C for 5 minutes;

[0030] 3. Add 5 parts of talc powder and 1 part of vinyl acetate, stir for 15 minutes to prepare liquid B, add water to liquid B and raise the temperature to 100°C and reflux for 16 hours to obtain a graphene solution;

[0031] 4. Dry the graphene solution to remove moisture to obtain a dry material, and finally obtain a modified graphene material by grinding or ball milling.

[0032] 2. Preparation of rubber composite materials

[0033] 1. Add 110 parts of th...

Embodiment 2

[0036] Embodiment 2 A kind of graphene modified rubber composite material and mixing method thereof for tire tread, comprising:

[0037] 1. Preparation of modified graphene materials

[0038] 1. Add 25 parts of graphene powder and N,N-dimethylamide solution into the stirring tank, stir at room temperature, raise the temperature to 60°C, add water to stir and dilute, and form A liquid;

[0039] 2. Preheat the stirred tank to 80°C, then add 17 parts of polyvinyl chloride powder and keep the temperature at 90°C and stir for 7 minutes;

[0040] 3. Add 7 parts of talcum powder and 2 parts of vinyl acetate, stir for 17 minutes to prepare liquid B, add water to liquid B and raise the temperature to 100°C and reflux for 20 hours to obtain graphene solution;

[0041] 4. Dry the graphene solution to remove moisture to obtain a dry material, and finally obtain a modified graphene material by grinding or ball milling.

[0042] 2. Preparation of rubber composite materials

[0043] 1. Ad...

Embodiment 3

[0046] Embodiment 3 A kind of graphene modified rubber composite material and mixing method thereof for tire tread, comprising:

[0047] 1. Preparation of modified graphene materials

[0048] 1. Add 30 parts of graphene powder and N,N-dimethylamide solution into the stirring tank, stir at room temperature, raise the temperature to 60°C, add water to stir and dilute, and form A liquid;

[0049] 2. Preheat the stirring tank to 80°C, then add 20 parts of polyvinyl chloride powder and keep stirring at 100°C for 10 minutes;

[0050] 3. Add 9 parts of talc powder and 3 parts of vinyl acetate, stir for 20 minutes to prepare liquid B, add water to liquid B and raise the temperature to 100°C and reflux for 24 hours to obtain a graphene solution;

[0051] 4. Dry the graphene solution to remove moisture to obtain a dry material, and finally obtain a modified graphene material by grinding or ball milling.

[0052] 2. Preparation of rubber composite materials

[0053] 1. Add 80 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com