Preparation method of polylactic acid food packaging film with antibacterial property and one-way moisture resistance

A technology of food packaging film and polylactic acid film layer, applied in coating and other directions, can solve the problems of poor heat resistance of natural antibacterial agents, limited promotion and use, long crosslinking time, etc., and achieves high antibacterial activity, easy promotion, and slow migration. the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

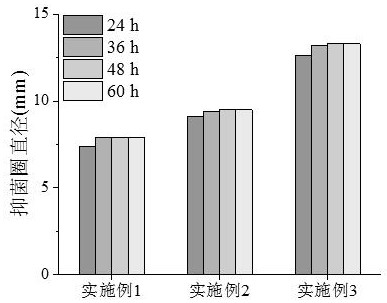

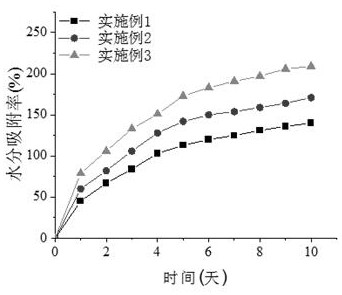

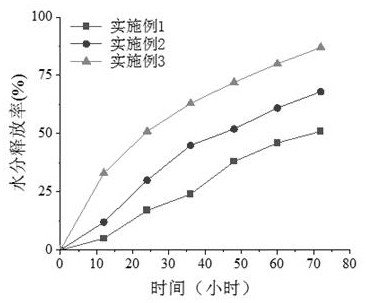

Embodiment 1

[0020] (1) Preparation of the polylactic acid film layer: Weigh 2g of polylactic acid and dissolve it in 100mL of chloroform solution, add 0.6g of glycerin as a plasticizer, stir to dissolve it completely, and ultrasonically degas to obtain a polylactic acid solution. Then pour it into a 20×20cm self-made glass plate, put it in a fume hood, and dry it at room temperature to obtain a polylactic acid film layer;

[0021] (2) Preparation of antibacterial gelatin gel solution: Weigh 2g of gelatin and disperse it in 100mL of water, stir and heat to 70°C to fully dissolve, then cool to 40°C, add 2mg of tannic acid and 1mg of ferric chloride, NaOH was used to adjust the pH value of the solution to 7.0, and continued to stir at 40° C. for 5 minutes to form a gel solution. Add 0.1 g of silver nitrate to the gel solution and stir at 40° C. for 30 minutes to obtain an antibacterial gelatin gel solution.

[0022] (3) Pour the antibacterial gelatin gel solution onto the surface of the poly...

Embodiment 2

[0024] (1) Preparation of polylactic acid film layer: Weigh 3g of polylactic acid and dissolve it in 100mL of chloroform solution, add 0.9g of glycerin as a plasticizer, stir to dissolve it completely, and ultrasonically degas to obtain a polylactic acid solution. Then pour it into a 20×20cm self-made glass plate, put it in a fume hood, and dry it at room temperature to obtain a polylactic acid film layer;

[0025] (2) Preparation of antibacterial gelatin gel solution: Weigh 3g of gelatin and disperse it in 100mL of water, stir and heat to 70°C to fully dissolve, then cool to 40°C, add 4mg of tannic acid and 2mg of ferric chloride, Use NaOH to adjust the pH value of the solution to 7.5, and continue stirring at 40°C for 5 minutes to form a gel solution, add 0.15g of silver nitrate to the gel solution, and stir at 40°C for 75 minutes to obtain an antibacterial gelatin gel solution;

[0026] (3) Pour the antibacterial gelatin gel solution onto the surface of the polylactic acid ...

Embodiment 3

[0028] (1) Preparation of polylactic acid film layer: Weigh 4g of polylactic acid and dissolve it in 100mL of chloroform solution, add 1.2g of glycerin as a plasticizer, stir to dissolve it completely, and ultrasonically degas to obtain a polylactic acid solution. Then pour it into a 20×20cm self-made glass plate, put it in a fume hood, and dry it at room temperature to obtain a polylactic acid film layer;

[0029] (2) Preparation of antibacterial gelatin gel solution: Weigh 4g of gelatin and disperse it in 100mL of water, stir and heat to 70°C to fully dissolve it, then cool to 40°C, add 6mg of tannic acid and 3mg of ferric chloride, Use NaOH to adjust the pH value of the solution to 8.0, and continue stirring at 40°C for 5 minutes to form a gel solution, add 0.2g of silver nitrate to the gel solution, and stir for 120 minutes at 40°C to obtain an antibacterial gelatin gel solution;

[0030] (3) Pour the antibacterial gelatin gel solution onto the surface of the polylactic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com