A Combustion Chamber Boiler

A combustion chamber, mother-in-law technology, applied in the field of boilers, can solve the problems of increased harmful gas emissions, insufficient fuel combustion, and inability to fully burn the fuel in the boiler, and achieves the effect of improving the burning rate and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

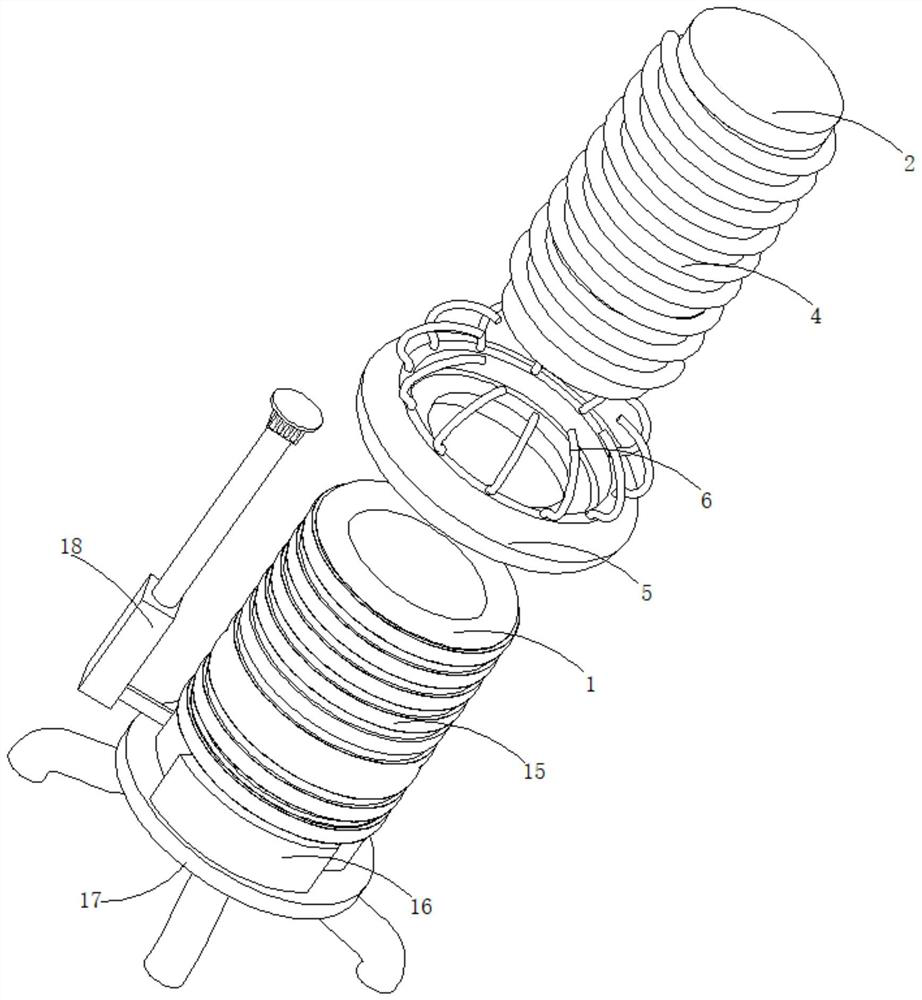

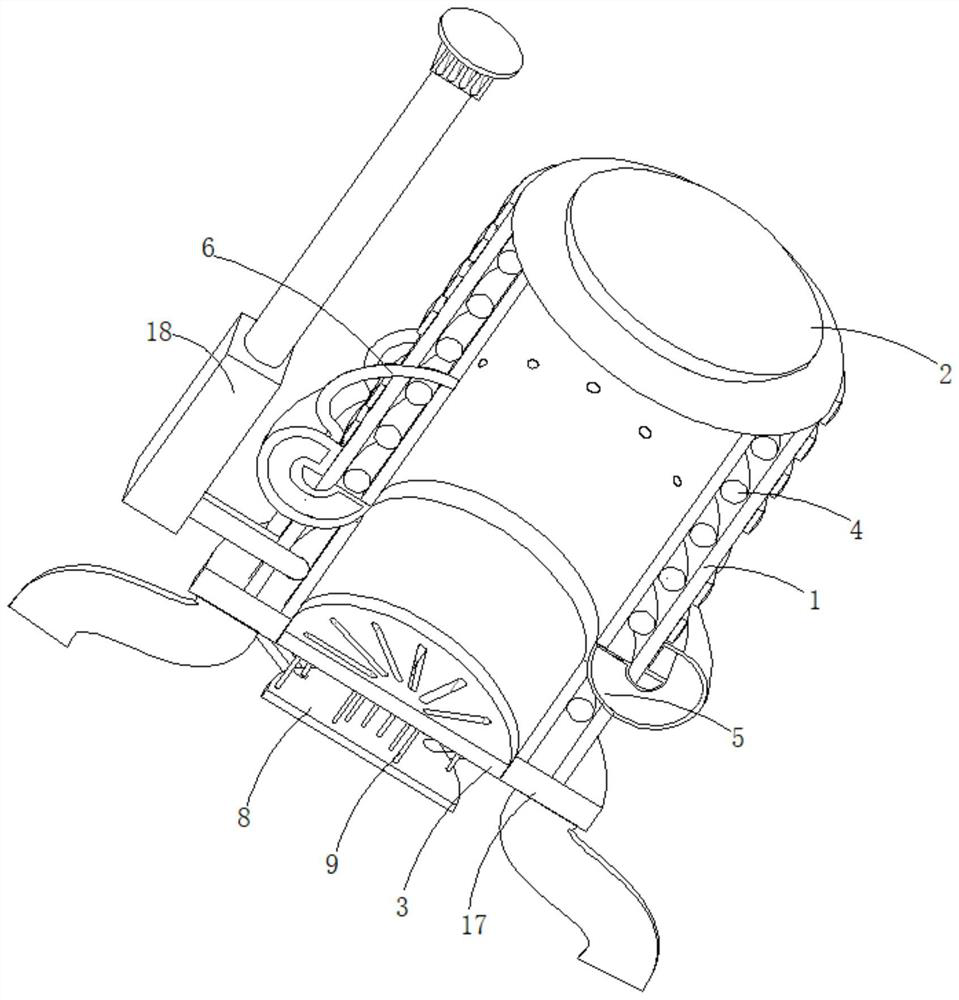

[0032] refer to Figure 1-5 , a mother-combustion boiler, comprising a main furnace body 1, a sub-furnace body 2 and a fire grate 3, the sub-furnace body 2 is sealed and connected in the main furnace body 1, and the outer wall of the sub-furnace body 2 is connected with a spirally wound smoke exhaust Pipe 4, the outer wall of the sub-furnace body 2 is also covered with a water storage member 5, the top edge of the water storage member 5 is connected with a first gas delivery pipe 6 and a second gas delivery pipe 7, the first gas delivery pipe 6 is far away from the water storage member 5 One end of the second gas pipe 7 extends inwardly through the sub-furnace body 2, and the end of the second gas delivery pipe 7 away from the water storage member 5 is connected to a transmission assembly, and the transmission end of the transmission assembly is connected to a cleaning rod 9 through a mounting plate 8;

[0033] A combustion chamber is provided in the sub-furnace body 2, and th...

Embodiment 2

[0039] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 6, a mother-combustion boiler, comprising a main furnace body 1, a sub-furnace body 2 and a fire grate 3, the sub-furnace body 2 is sealed and connected in the main furnace body 1, and the outer wall of the sub-furnace body 2 is connected with a spirally wound smoke exhaust Pipe 4, the outer wall of the sub-furnace body 2 is also covered with a water storage member 5, the top edge of the water storage member 5 is connected with a first gas delivery pipe 6 and a second gas delivery pipe 7, the first gas delivery pipe 6 is far away from the water storage member 5 One end of the second gas pipe 7 extends inwardly through the sub-furnace body 2, and the end of the second gas delivery pipe 7 away from the water storage member 5 is connected to a transmission assembly, and the transmission end of the transmission assembly is connected to a cleaning rod 9 through a mounting plate 8;

[0040] One end of the sm...

Embodiment 3

[0044] refer to Figure 6 , a master-combustion boiler, which is basically the same as Embodiment 2, and furthermore, the inner wall of the flue gas filter tower 18 is dug with a chute 22, and the coarse-pore filter plate 20 and the fine-pore filter plate 19 are all slidably connected On the inner wall of the flue gas filtering tower 18; the detachable structure realizes the function of easy replacement and improves the performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com