Dewatering and drying device for food processing

A technology for dehydration drying and food processing, applied in drying, dryer, food processing and other directions, can solve problems such as large safety and hidden dangers of hanging baskets, and achieve the goal of ensuring recycling efficiency, improving the quality of finished products, and improving drying efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

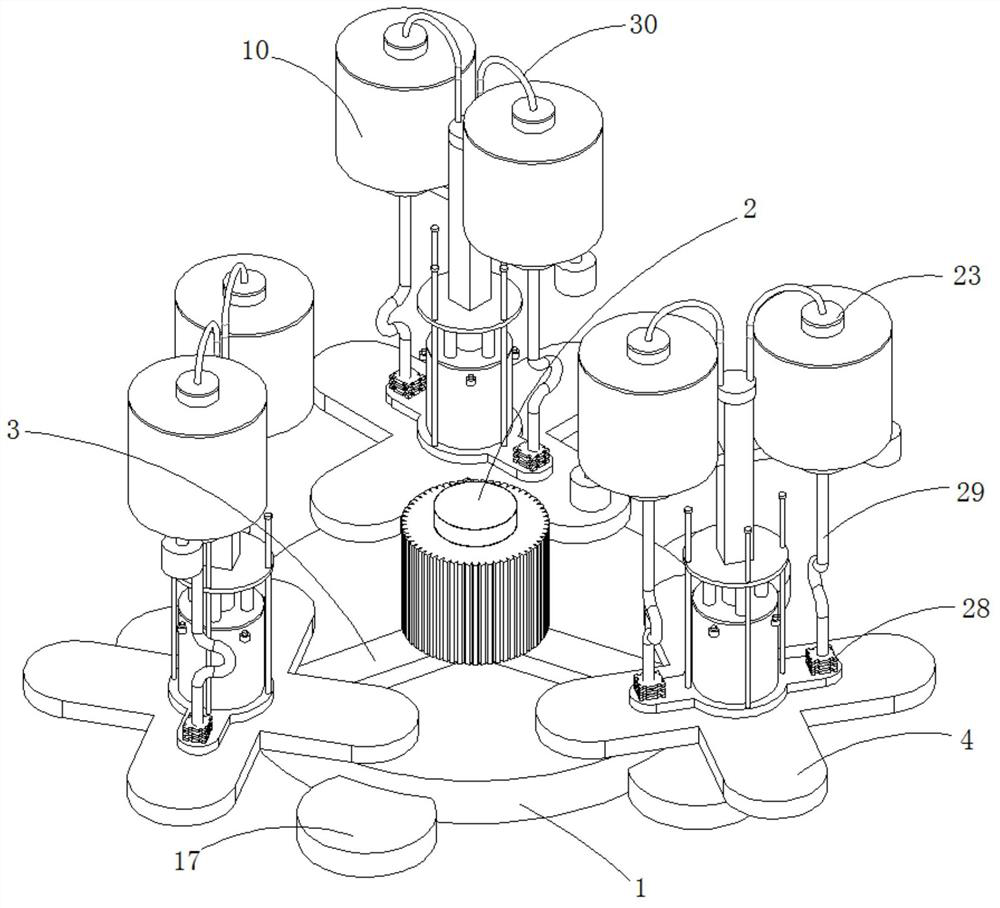

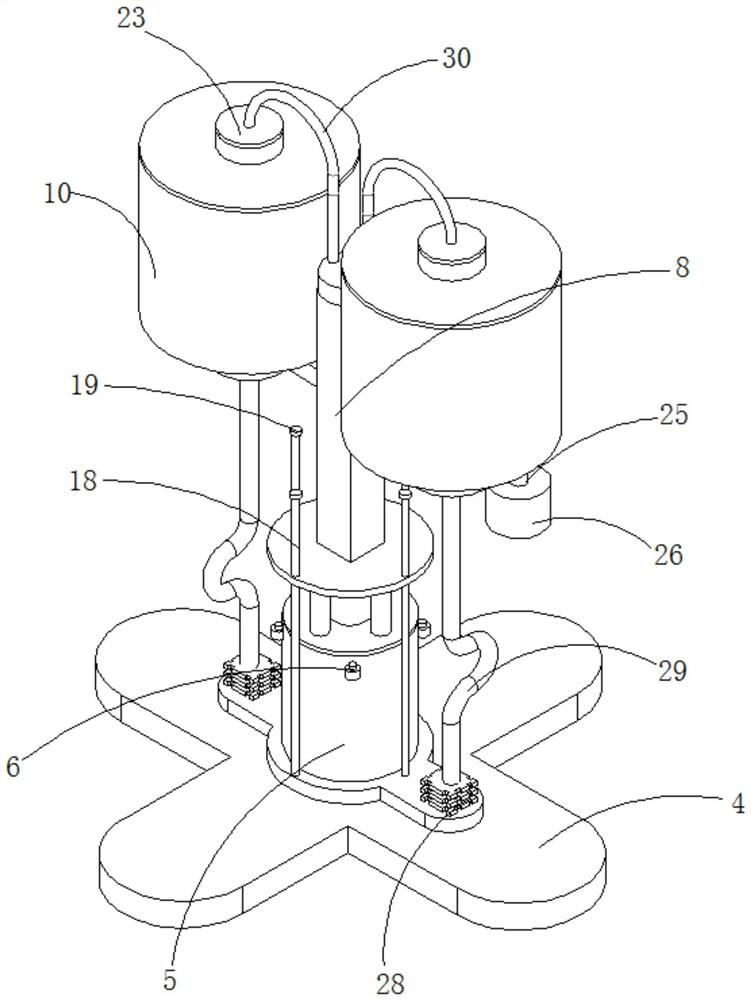

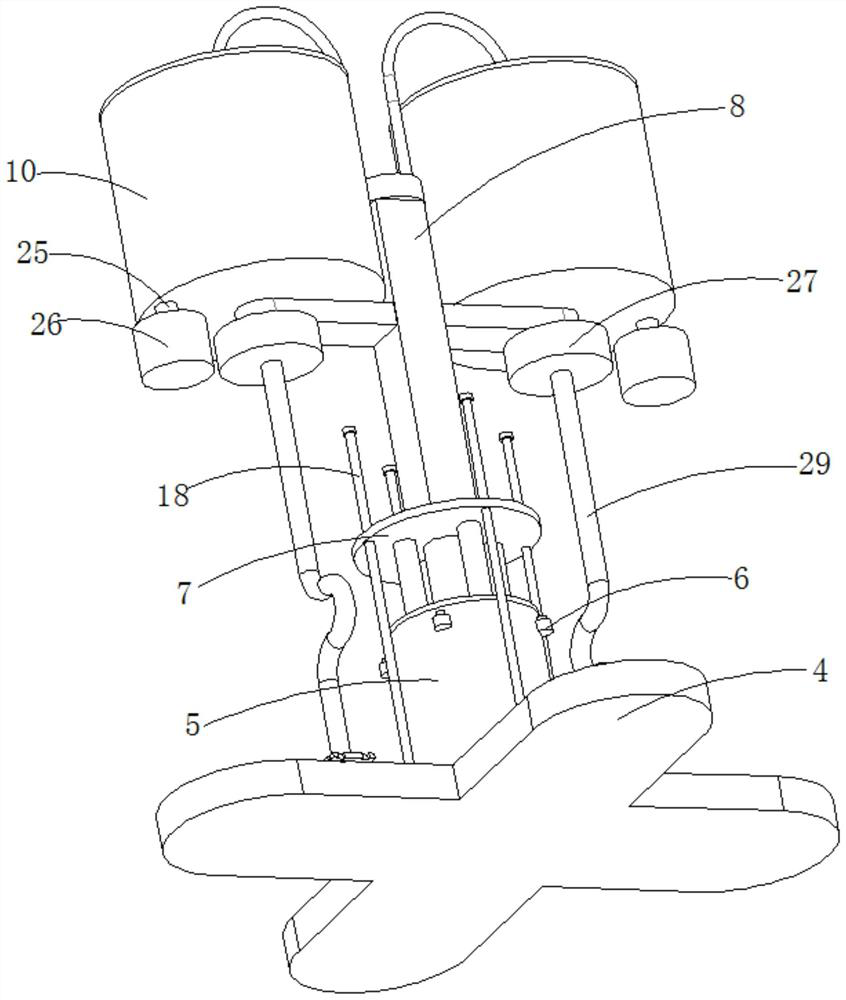

[0033]ReferenceFigure 1-7, A dehydration and drying device for food processing, comprising a base 1, a drive motor 2 is fixedly connected to the top center of the base 1, the drive end of the drive motor 2 is fixedly connected with a connecting frame 3, and the connecting end of the connecting frame 3 is fixed with The evenly distributed mounting plate 4, the top center of the mounting plate 4 is fixedly connected with an air cylinder 5, the outer side wall of the air cylinder 5 near the top is equipped with a pressure relief valve 6, the air cylinder 5 is provided with a reciprocating component, and the reciprocating end of the reciprocating component is connected with The fixing plate 7 is provided with a limit component between the mounting plate 4 and the fixing plate 7. A vertically arranged hollow mounting rod 8 is integrally formed at the top center of the fixing plate 7, and the outer side wall of the hollow mounting rod 8 is fixed with symmetrically distributed The support ...

Embodiment 2

[0046]ReferenceFigure 1-7, A dehydration and drying device for food processing, comprising a base 1, a drive motor 2 is fixedly connected to the top center of the base 1, the drive end of the drive motor 2 is fixedly connected with a connecting frame 3, and the connecting end of the connecting frame 3 is fixed with The evenly distributed mounting plate 4, the top center of the mounting plate 4 is fixedly connected with an air cylinder 5, the outer side wall of the air cylinder 5 near the top is equipped with a pressure relief valve 6, the air cylinder 5 is provided with a reciprocating component, and the reciprocating end of the reciprocating component is connected with The fixing plate 7 is provided with a limit component between the mounting plate 4 and the fixing plate 7. A vertically arranged hollow mounting rod 8 is integrally formed at the top center of the fixing plate 7, and the outer side wall of the hollow mounting rod 8 is fixed with symmetrically distributed The support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com