Reaction heat recycling device for petrochemical industry

A recovery device and industrial technology, applied in the direction of indirect heat exchangers, heat exchanger types, cleaning methods and appliances, etc., can solve the problems of heat energy consumption and inability to be better utilized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

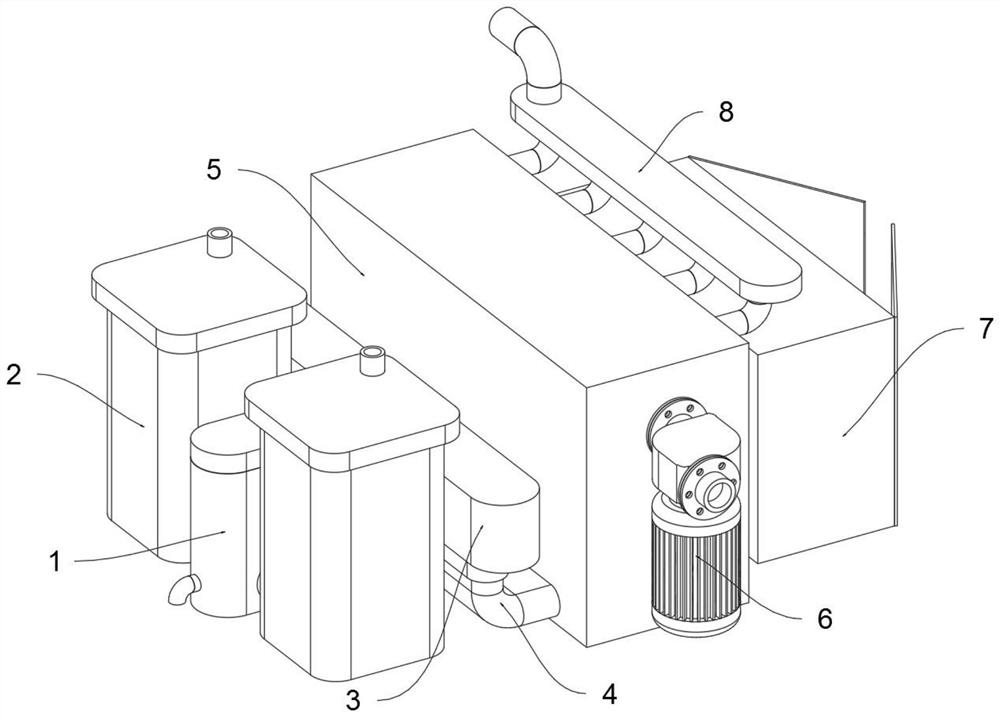

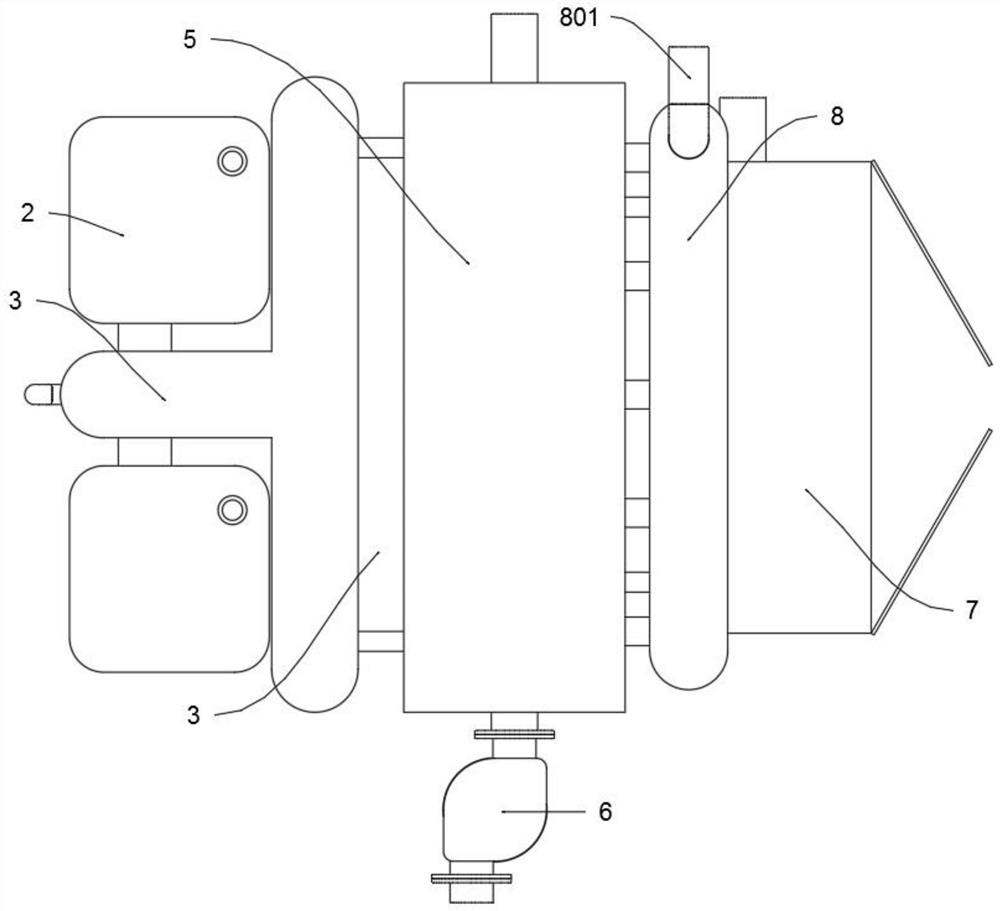

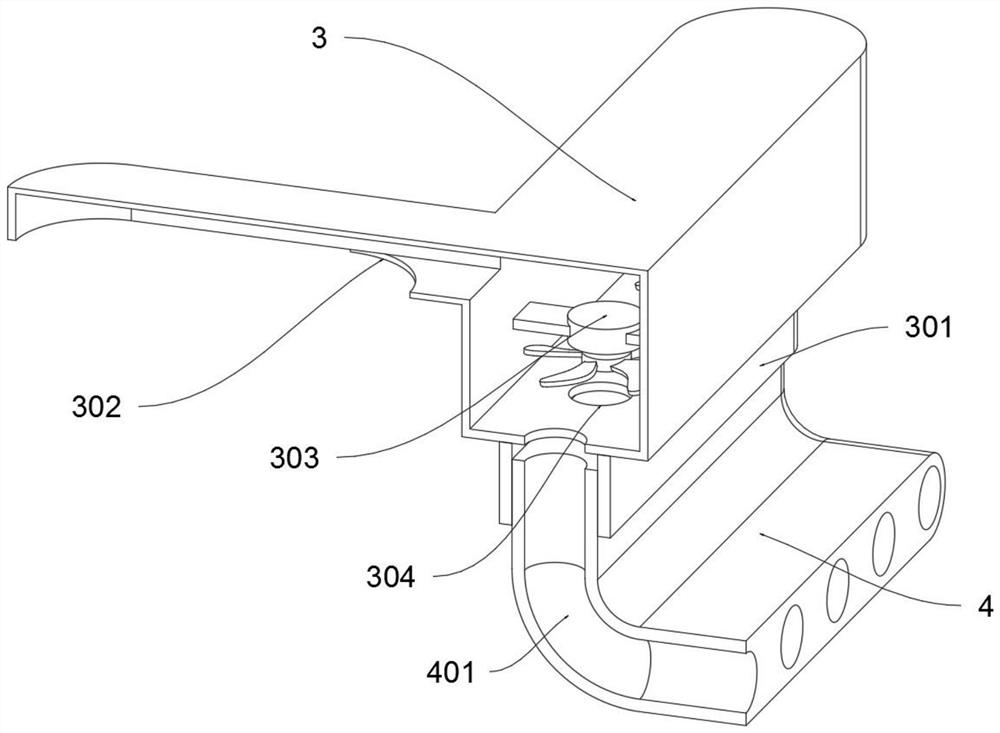

[0032] Append figure 1 Adherent Figure 7 Down:

[0033] The present invention provides a petrochemical reactive heat recovery device including a reactive tank 1, a guide hood 3, a thermostat 4, a heat transfer tank 5, an warming box 7, an exhaust gas collecting cover 8, a heat gas conduit 10; reaction tank 1 Through the catheter, the raw pad 2 is connected; the lower surface of the air cover 3 is fixed to the upper opening of the reaction tank 1 by the bolt; the upper end of the insulation guide 4 is fixedly attached to the bottom of the air exchanger 3; heat transfer box 5 The front side is connected to the flange 6; the right end of the insulation guide 4 is fixed to the heat transfer tank 5, and the heat exchange water pipe 501 of the heat transfer tank 5 is connected to the inside of the insulation guide cylinder 4; the exhaust gas collecting cover 8 is fixed by welding The heat transfer water pipe 501 of the heat transfer tank 5; the left end fixation of the heat gas conduit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com