Extraction device of pressure-type coffee machine

An extraction device, coffee machine technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of wasting materials and space, laborious and complicated operation, and achieve the effects of reducing pressure requirements, saving materials, and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

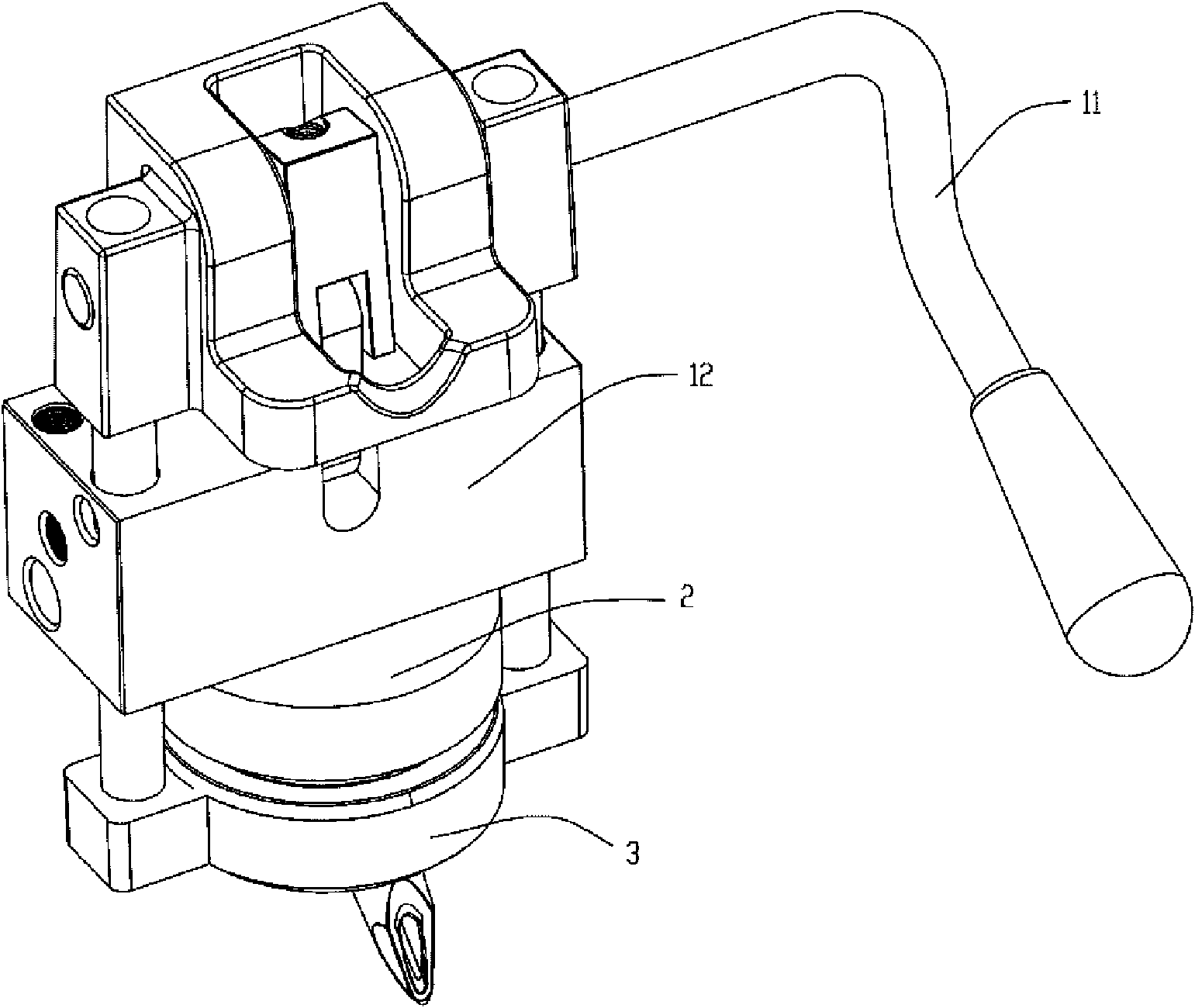

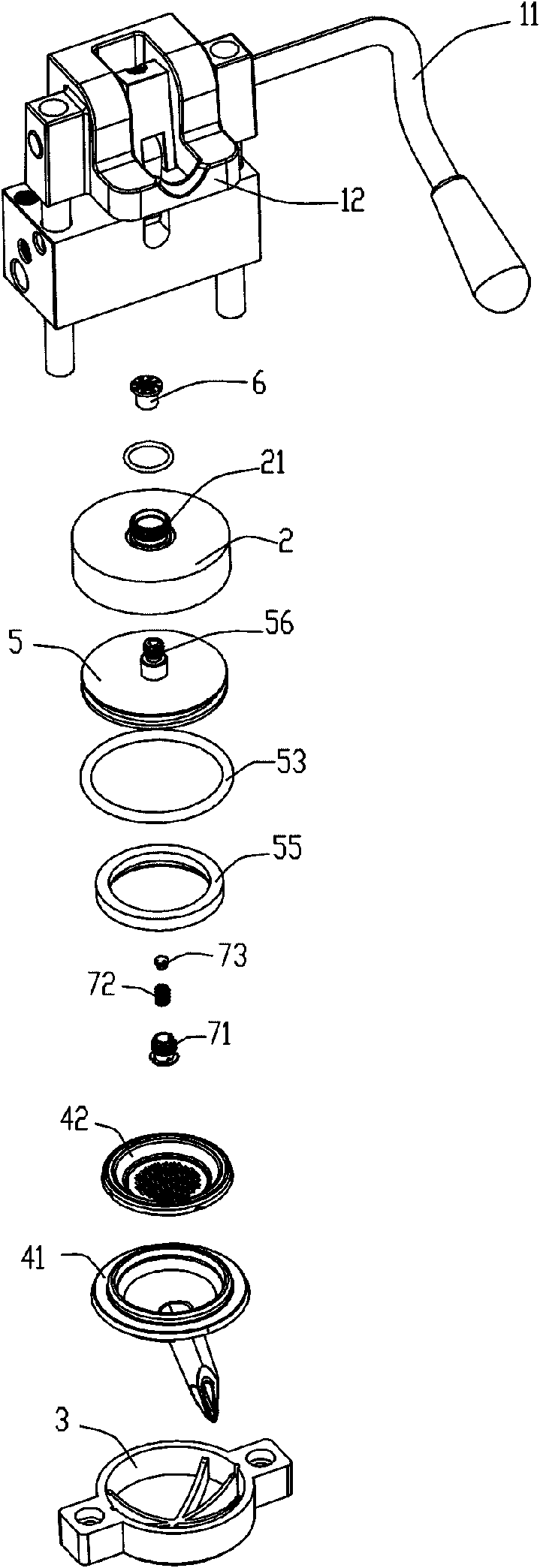

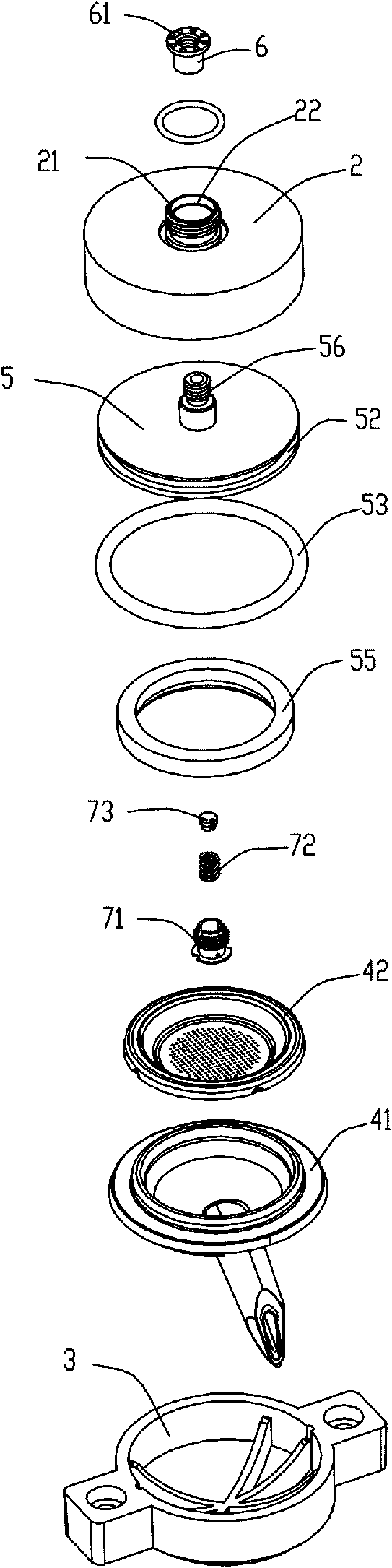

[0018] refer to Figure 1 to Figure 7 As shown, the extraction device of the pressure coffee machine includes a pressing assembly 12 driven by the handle 11 and can move up and down. The bottom of the pressing assembly 12 is equipped with a water outlet pressure block 2, and the middle part of the water outlet pressure block 2 extends upwards. There is a water inlet 21, and the coffee machine is provided with a fixed seat 3 corresponding to the water outlet pressure block 2, and a coffee collector 41 and a filter screen 42 are arranged in the fixed seat 3, and an inner concave cavity is arranged at the bottom of the water outlet pressure block 2 22. The inner concave cavity 22 is equipped with an auxiliary pressing block 5 that can be moved downward by water pressure, and there is a limit between the water outlet pressing block 2 and the auxiliary pressing block 5 that limits the maximum downward movement distance of the auxiliary pressing block 5 device, the middle of the aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com