Exhaust gas diffuser of a gas turbine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

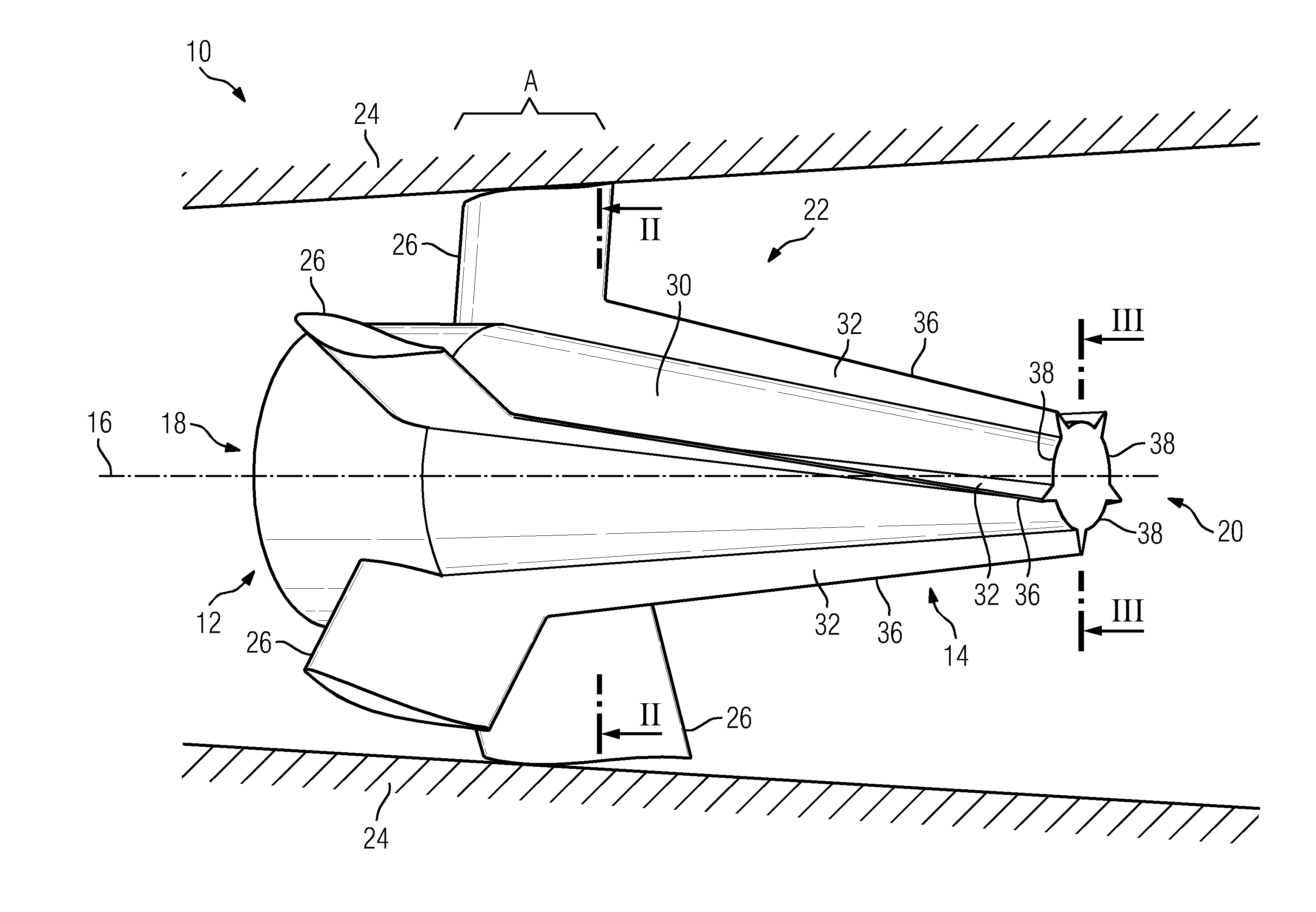

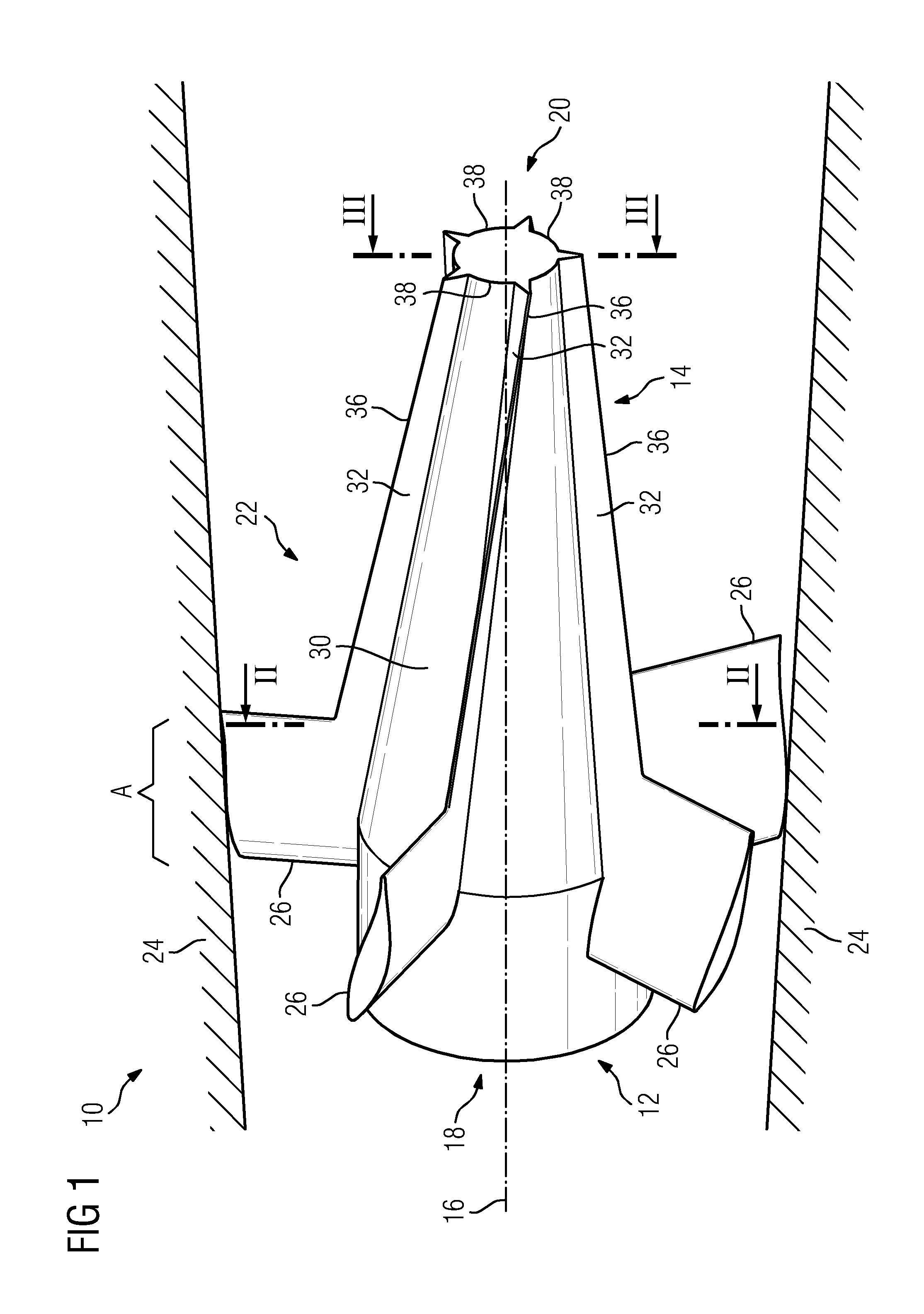

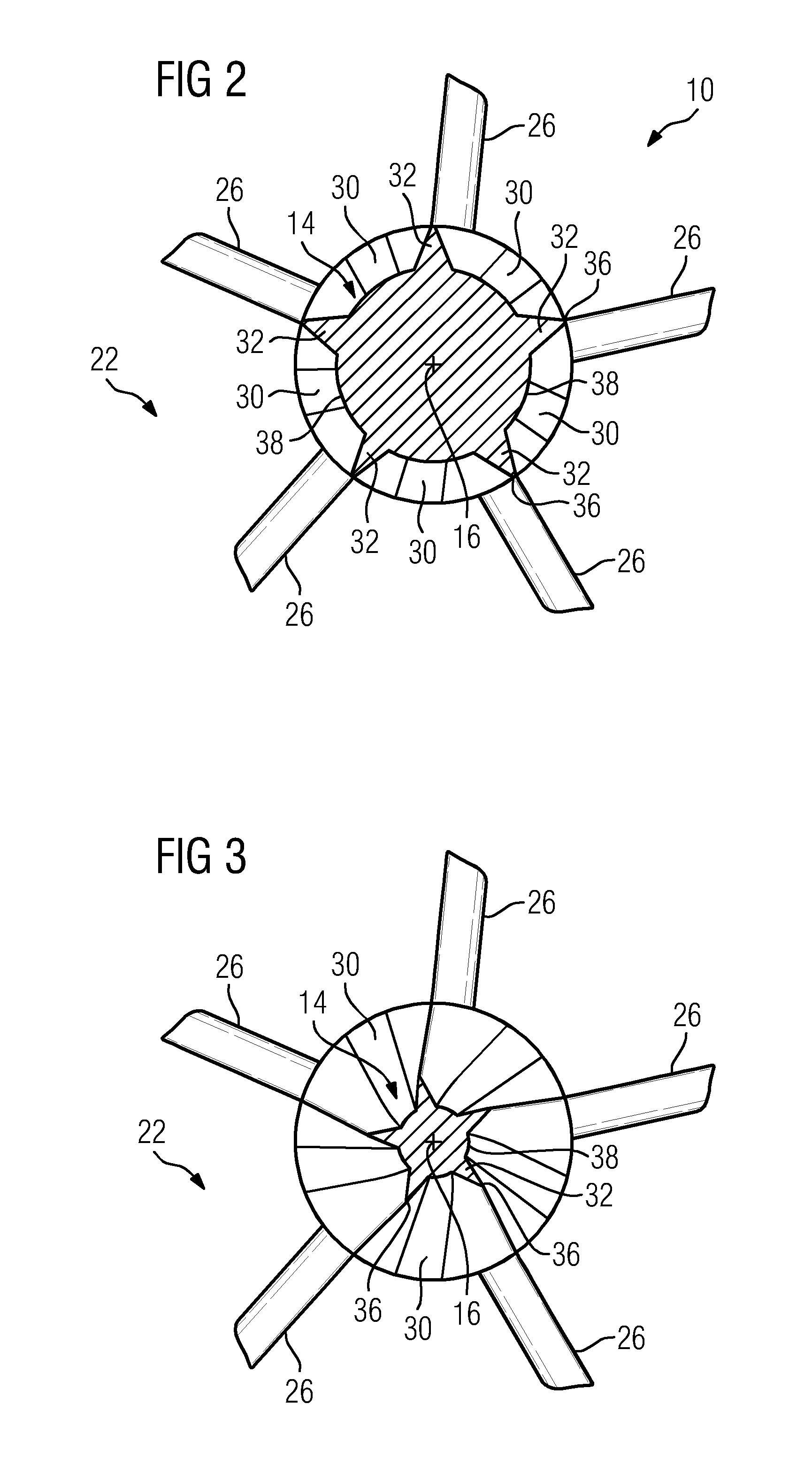

[0017]Shown in FIG. 1 is an exhaust gas diffuser 10 for a gas turbine in a longitudinal section, wherein the bearing star 12, which is arranged in the center of the exhaust gas diffuser 10, for the turbine-side support of the gas turbine rotor and of the guide body 14 which is arranged on the bearing star, is shown in perspective view. The exhaust gas diffuser 10 has a center axis 16 lying in its center, which extends from an inlet-side end 18 to an outlet-side end 20. Provision is made in the exhaust gas diffuser 10 for a flow duct 22, the cross section of which, being perpendicular to the center axis, has an annular contour. The flow duct 22 is delimited in this case by a radially outward disposed outer wall 24. The guide body 14 is arranged in the center of the exhaust gas diffuser 10, that is to say in the region of its center axis 16, and in this case constitutes the radially inward disposed boundary of the flow duct 22. The guide body 14 is supported in this case by five suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com