Water hyacinth carboxymethyl cellulose salt-resistant and super absorbent resin and preparation method thereof

A technology of carboxymethyl cellulose and superabsorbent resin, which is applied in the field of water-absorbent resin preparation, can solve the problems of non-degradable water-absorbent resin, occupying land for landfill, and lower water absorption rate, etc., to achieve high repeated water absorption capacity, minimize pollution, and save energy. The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

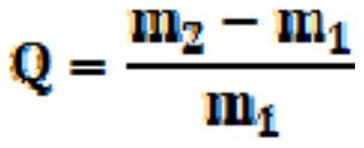

Image

Examples

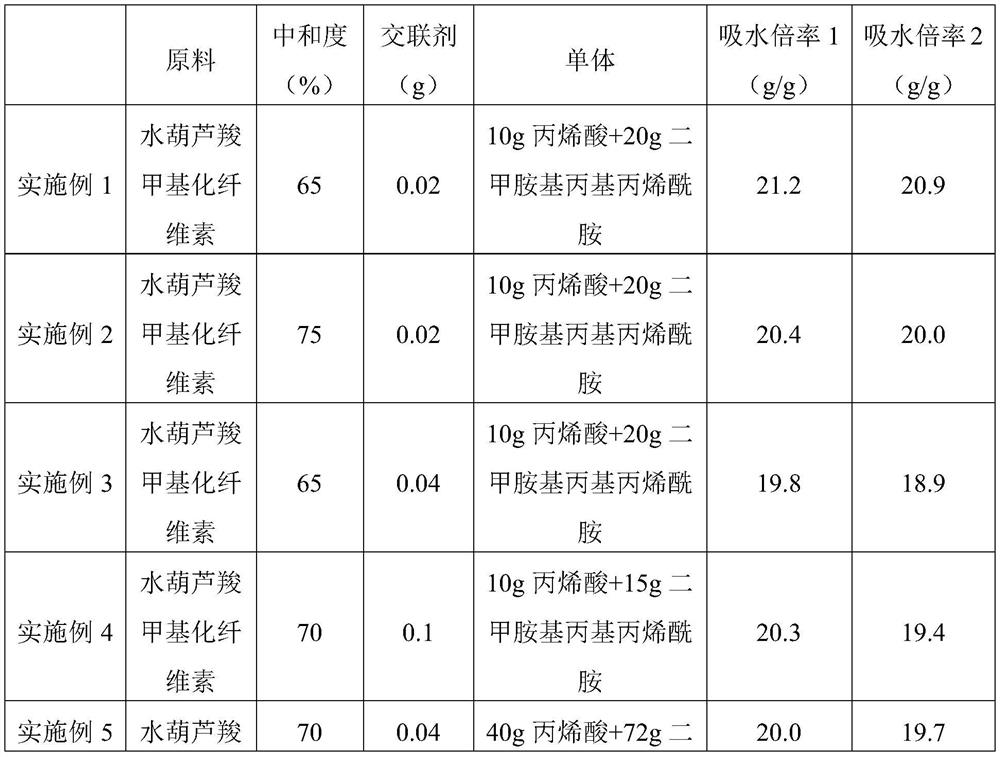

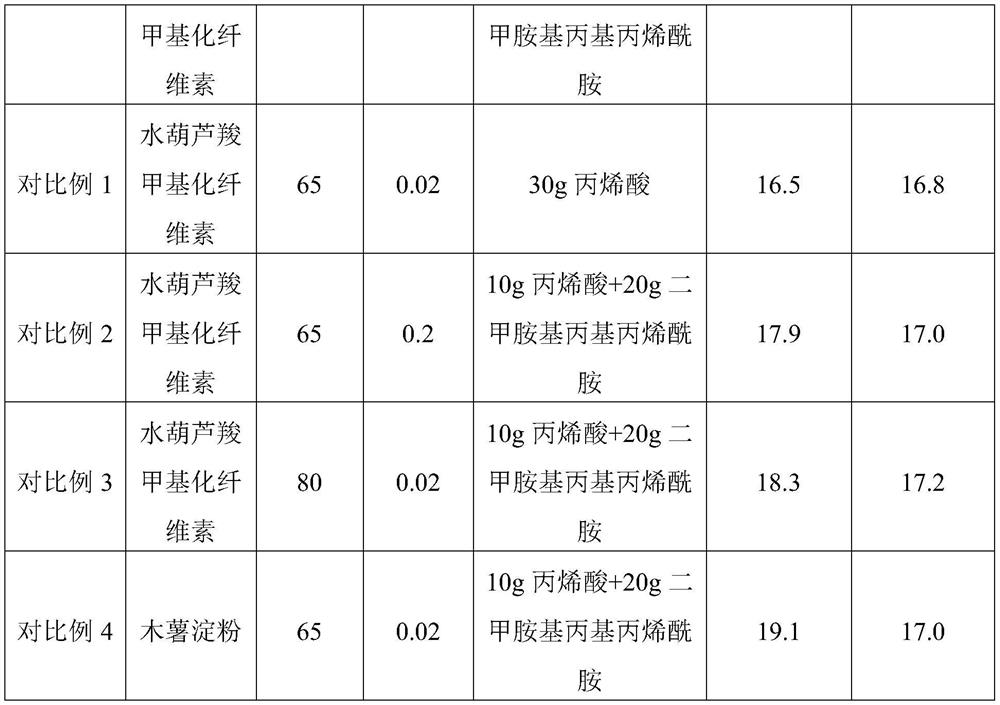

Embodiment 1

[0026] A water hyacinth carboxymethyl cellulose salt-resistant-superabsorbent resin, the preparation method of which comprises the steps of:

[0027] Take 10g of acrylic acid, add sodium hydroxide with a mass fraction of 25% to neutralize the acrylic acid to a neutralization degree of 65%, add 20g of dimethylaminopropyl acrylamide to the neutralized acrylic acid, and keep stirring at 400r / min 0.5h, after mixing evenly, a mixed monomer solution was obtained.

[0028] The sample was prepared by the aqueous solution polymerization method. First, mix 1 g of water hyacinth carboxymethylated cellulose with 20 g of pure water and put it into a three-necked round-bottomed flask. Heat the oil bath to 90 ° C, stir with 400 r / min magnetic force for 0.5 h, condense and reflux for about 1h, cool down to 60°C and keep warm.

[0029] Nitrogen was passed through water hyacinth carboxymethylated cellulose at 15mL / min, and 0.15g potassium persulfate and 0.05g sodium bisulfite were added as ini...

Embodiment 2

[0032] A water hyacinth carboxymethyl cellulose salt-resistant-superabsorbent resin, the preparation method of which comprises the steps of:

[0033] Take 10g of acrylic acid, add sodium hydroxide with a mass fraction of 25% to neutralize the acrylic acid to a neutralization degree of 75%, add 20g of dimethylaminopropyl acrylamide to the neutralized acrylic acid, and keep stirring at 200r / min 0.8h, after mixing uniformly, a mixed monomer solution was obtained.

[0034] The sample was prepared by the aqueous solution polymerization method. First, mix 1 g of water hyacinth carboxymethylated cellulose with 20 g of pure water and put it into a three-necked round-bottomed flask. Heat the oil bath to 90 ° C, stir with 300 r / min magnetic force for 1 h, and condense and reflux for about 1 h. , cooled to 60°C and kept warm.

[0035] Nitrogen gas was passed through water hyacinth carboxymethylated cellulose at 10mL / min, and 0.15g potassium persulfate and 0.05g sodium bisulfite were add...

Embodiment 3

[0038] A water hyacinth carboxymethyl cellulose salt-resistant-superabsorbent resin, the preparation method of which comprises the steps of:

[0039] Take 10g of acrylic acid, add sodium hydroxide with a mass fraction of 25% to neutralize the acrylic acid to a neutralization degree of 65%, add 20g of dimethylaminopropyl acrylamide to the neutralized acrylic acid, and keep stirring at 300r / min 1h, after mixing uniformly, a mixed monomer solution was obtained.

[0040] The sample was prepared by the aqueous solution polymerization method. First, mix 1 g of water hyacinth carboxymethylated cellulose with 20 g of pure water and put it into a three-necked round-bottomed flask. Heat the oil bath to 90 ° C, continue stirring at 200 r / min for 0.8 h, condense and reflux for about 1h, cool down to 60°C and keep warm.

[0041] Nitrogen was passed through water hyacinth carboxymethylated cellulose at 12mL / min, and 0.15g potassium persulfate and 0.05g sodium bisulfite were added as initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com