Solid waste incinerator without emission of flue gas

A solid waste and incinerator technology, applied in the direction of incinerators, emission prevention, combustion methods, etc., can solve the problems of low thermal efficiency of incinerators, unstable furnace temperature, waste of resources, etc., and achieve significant emission reduction and energy saving effects , The effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail by the following examples.

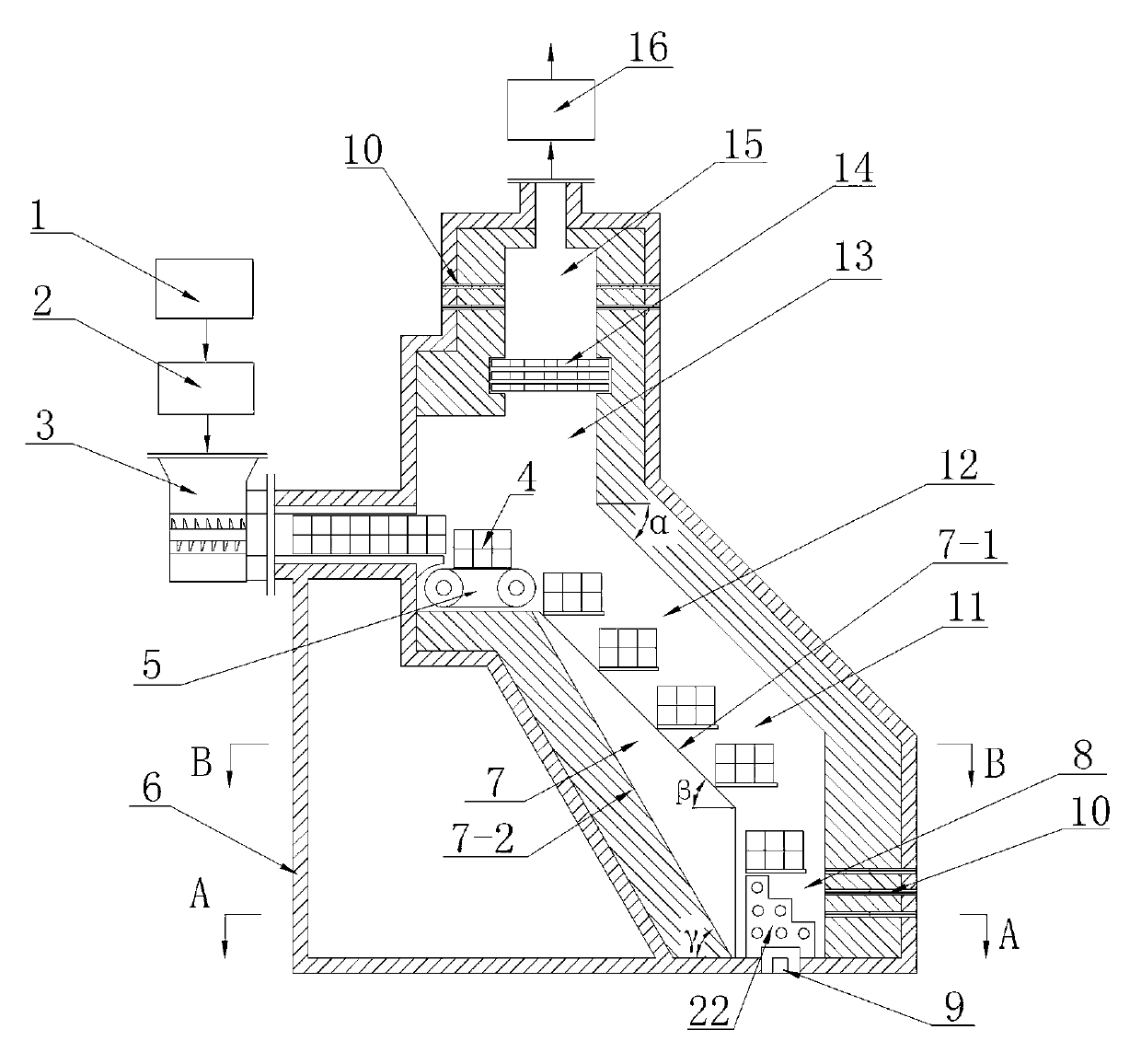

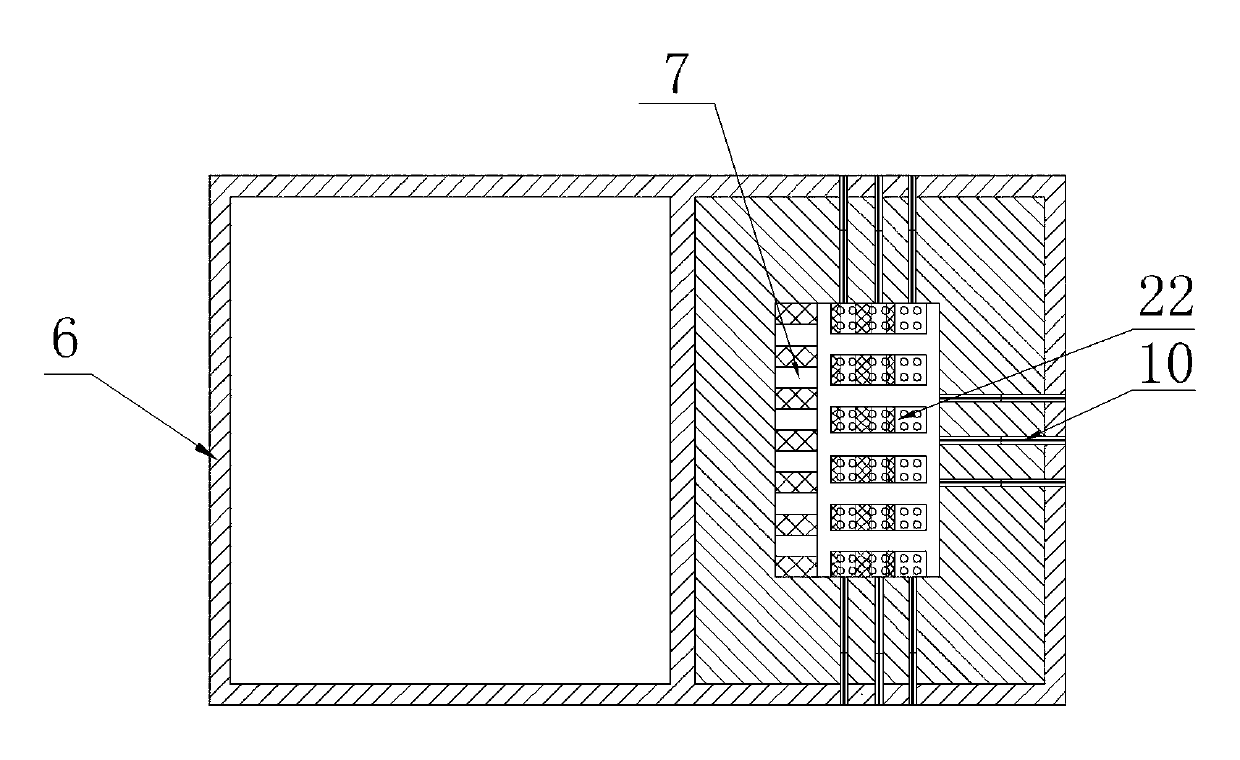

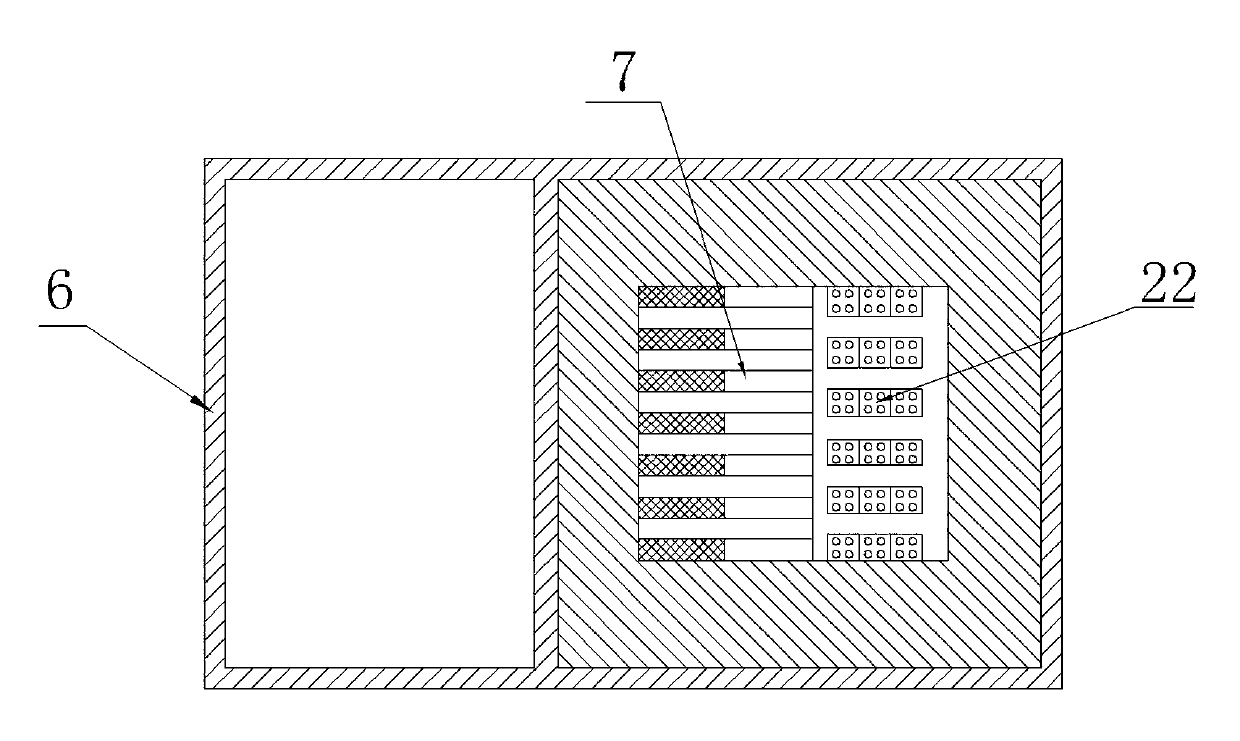

[0025] see figure 1 — Figure 4 As shown, a solid waste incinerator without flue gas emission consists of an incinerator body 6, a vertically structured incinerator hearth 13, a crusher 1, a mixing mixer 2, a compression molding machine 3, and a high temperature resistant belt conveyor 5, boiler furnace 15, induced draft fan 16, heat exchanger 17, desulfurization device 18, purification device 19, carbon dioxide separation device 20, gas mixer 21. The furnace 13 of the incinerator is provided with a drying area 12 , a pyrolysis area 11 and a combustion area 8 sequentially from top to bottom. The bottom of the combustion area 8 is provided with an ash outlet 9 , and the ash outlet 9 is provided with a grid 22 . The cross-section of the incinerator hearth 13 is square, and on the left side of the drying zone 12, the pyrolysis zone 11, and the combustion zone 8 of the incinerator hearth 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com