A treatment method for recycling dyeing residue

A technology for dyeing residue and treatment method, applied in the field of wastewater treatment in the printing and dyeing industry, can solve the problems of complex equipment, complex treatment process, and high treatment costs, and achieve the effect of reducing operating costs, easily reaching discharge standards, and achieving discharge standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a treatment method for recycling the dyeing residue, adding an organic liquid to the acidic dyeing residue, so that the color-developing substances in the dyeing residue are separated into the organic liquid, thereby decolorizing the dyeing residue ; The dyeing residue after decolorization treatment is reused according to the dyeing process.

[0048] The method specifically comprises: collecting 6000 ml of dyeing residue in a reactor, slowly adding sulfuric acid to make the pH of the residue 3-4. Mix tributyl phosphate and aviation kerosene at a volume ratio of 2:8 to obtain an organic liquid, take 200ml of the organic liquid and add it to the dyeing residue with adjusted pH for decolorization treatment, react for 30 minutes, let it stand for 30 minutes, and separate the lower layer for decolorization Nearly colorless dyeing residue after treatment and loaded organic liquid loaded with dyes. Add 35ml of sodium hydroxide solution with a mass con...

Embodiment 2

[0055] This embodiment provides a treatment method for recycling the dyeing residue, adding an organic liquid to the acidic dyeing residue, so that the color-developing substances in the dyeing residue are separated into the organic liquid, thereby decolorizing the dyeing residue ; The dyeing residue after decolorization treatment is reused according to the dyeing process.

[0056] The method specifically comprises: collecting 6000 ml of dyeing residue in a reactor, slowly adding sulfuric acid to make the pH of the residue 3-4. Mix trioctyl phosphate and aviation kerosene in a volume ratio of 3:7 to obtain an organic liquid. Take 160ml of the organic liquid and add it to the dyeing residue with adjusted pH for decolorization treatment. After reacting for 45 minutes, let it stand for 45 minutes, and separate the lower layer for decolorization. After treatment, the near-colorless dyeing residue and the loaded organic liquid loaded with dyes. Add 40ml of potassium hydroxide solu...

Embodiment 3

[0060] This embodiment provides a treatment method for recycling the dyeing residue, adding an organic liquid to the acidic dyeing residue, so that the color-developing substances in the dyeing residue are separated into the organic liquid, thereby decolorizing the dyeing residue ; The dyeing residue after decolorization treatment is reused according to the dyeing process.

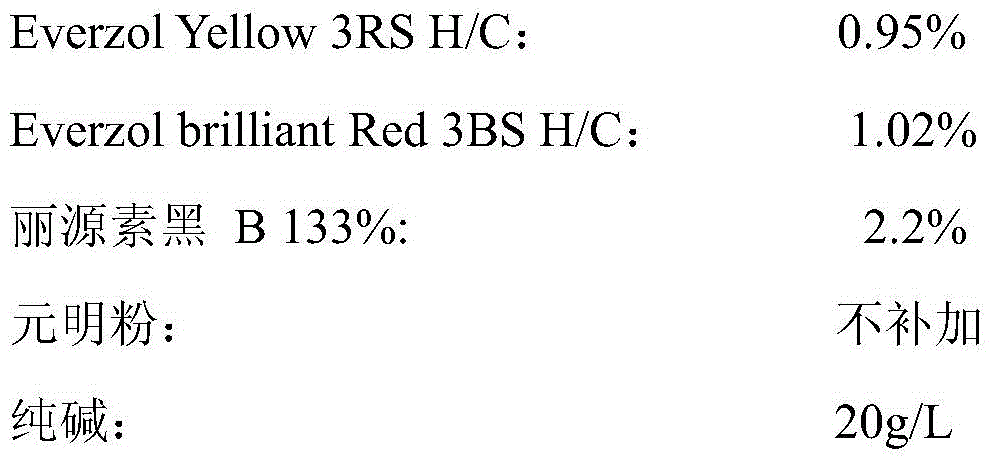

[0061] The method specifically comprises: collecting 6000 ml of the raffinate in a reactor, and slowly adding sulfuric acid to make the pH of the raffinate 3-4. Mix trioctylphosphine and sulfonated kerosene evenly at a volume ratio of 4:6 to obtain an organic liquid, take 150ml of the organic liquid and add it to the dyeing residue with adjusted pH for decolorization treatment, react for 60 minutes, let it stand for 60 minutes, and separate The near-colorless dyeing residue after the decolorization treatment of the lower layer and the loaded organic liquid loaded with dyes. Add 30ml of sodium carbonate so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com